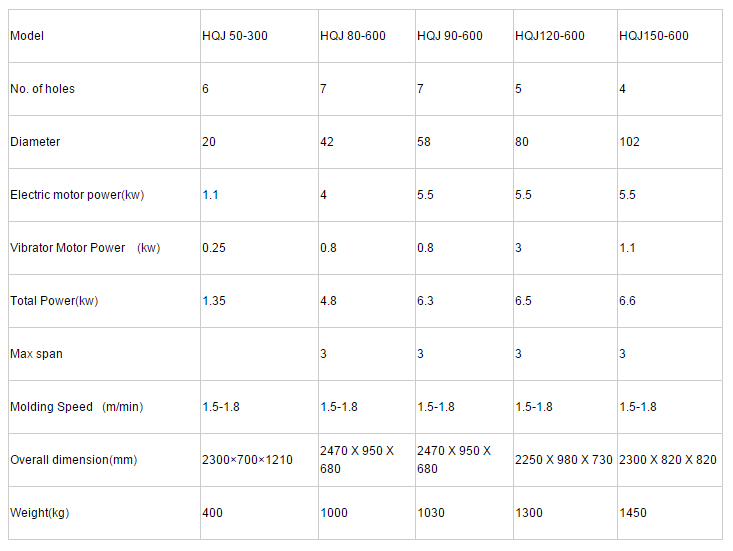

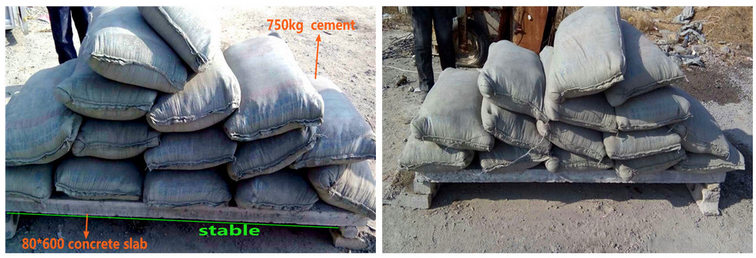

HQJ 90-600 Lightweight concrete wall panel forming machine

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 5 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details

· Condition: New

· Application: prefab building

· Automatic Grade: Automatic

· Production Capacity: 60-70m/h

· Place of Origin: Shandong, China (Mainland)

· Brand Name: LING FENG

· Model Number: SL80*600

· Voltage: 360v

· Power(W): 4.5-8.0kw

· Dimension(L*W*H): 2.5*1.0*1.0m

· Weight: 2.0T

· Features: high efficiency

· Certification: ISO9001/CE

· Warranty: 12 months

· After-sales Service Provided: Engineers available to service machinery overseas

· Main frame: 2.0*1.4m

· Color steel thickness: 0.3-0.8 mm

· Insulation: first class

· Shaft axis: diameter 80

· Brick Raw Material: Cement, sand, stone.

· Strength: water proof, fireproof, sound proof

· Vibrator type: ZW type 3.0kw

· Motor model: YEZ132S-4-B5

· Color: yellow or custom

· OEM: available

Products

Quality

Packaging & Delivery

Packaging Details: Wooden case and wood flour into the bottom of the box.

Delivery Detail: Within 15 days

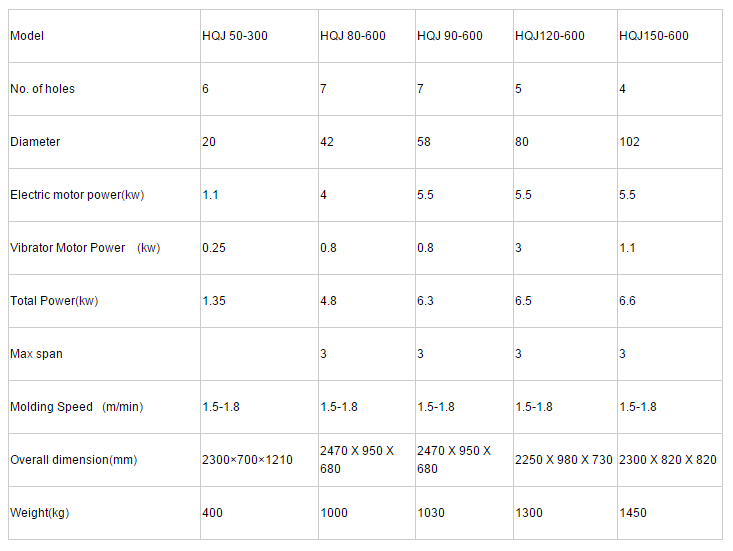

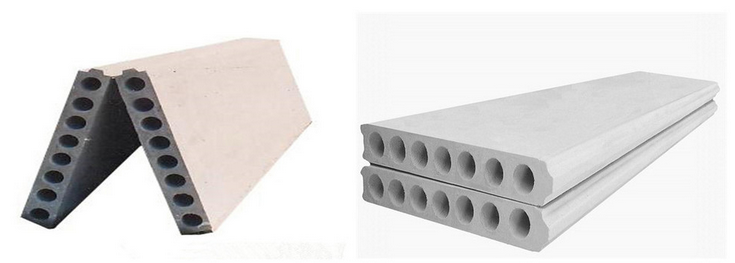

Major Parts and advantage of lightweight wall panel machine

Features:

I. Anti-corrosion and wear-resistant.

The machine frame is made of manganese steel whose quality is better than normal steel. The interior side of the mould is made of stainless steel (its thickness can be 2.2mm) which can stand repeated use and corrosive materials. It can be used for over 10 years. Besides, panels made by this kind of machine have better quality than other kinds. The panel will not be deformed. Its surface is smoother than others.

II. High capacity

Normal hollow core wall panel machine can make only ten panels in one mould, but this machine can make 14 panels at one time.

III. Energy-saving

The machine uses storage battery as power which can save a lot of electricity and is safe to use. Besides, if there is something wrong with the machine in the production line, it will not influence the use of other machines.

IV. Lower the cost of production

We use stainless steel for the mould instead of traditional steel. Steel mould machines need brushing de-molding agent or the panels can't be taken out. Stainless steel machines need a little de-molding agent, this can save both labor and material cost for manufacturers.

V. Hydraulic mould closing and opening

The mould is opened and closed by hydraulic. Its moving is very smooth and stable. All the four sides of the mould can be opened together, so it is very easy to use and it can save labor and cost.

VI. Unique design

We have special design not only for the single machine, but also for the whole production line. Our mixer can be customized for the customer according to their requirement. We also have special equipment to get rid of the dust so that the production is very clean.

Our Services

Interests in the good faith, interests in quality, interests in the service

Customer visits and technical guidance provides 24-hour service and lifetime maintenance services, supply of spare parts. Site church consumer operation, teach operating essentials, equipment maintenance and production experience, considerations.

Our factory can produce all kinds of equipment and prefabricated factory accessories according to customer demand.

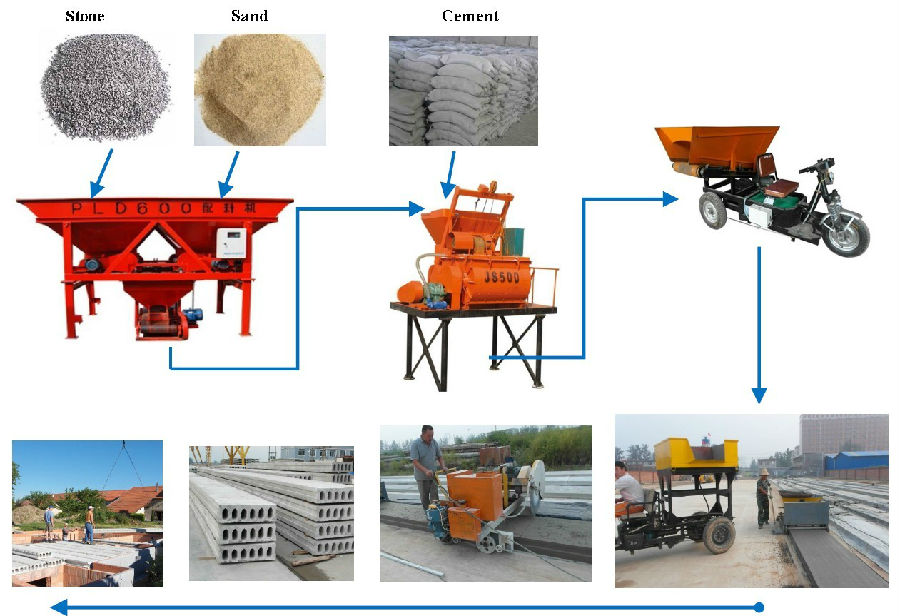

Flow chart:

Other available machines:

- Q:electrical machineries

- For large or largish generators steam turbines gas turbines wind turbines water turbines diesel engines

- Q:Bally Manufacturing sent Intel Corporation an invoice for machinery with a $20,000 list price. Bally dated the invoice July 23 with 2/10 EOM terms. Intel receives a 40% trade discount. Intel pays the invoice on August 5.

- Yeah, so what's the question really? (You don't really state what you want answered). But anyways, Intel missed the 10 day discount period on the payment terms, so they can't take that. ------------------------ It's also hard to tell if the trade discount is already included in the invoice amount (which it should be).

- Q:Do you know how to handle heavy machinery?

- Yes especially on weekends

- Q:car, machinery diagnostic type person.

- right!!!!!!!

- Q:Can anybody knows the Journal entry of purchase Plant & Machinery?

- They are fixed assets/plant assets. The assets include equipment, machinery, buildings, and land. They all depreciate over a period of time except land.

- Q:Classification of materials in machinery industry

- Machinery industry materials are divided into two categories of metal materials and non-metallic materials, metal materials are divided into ferrous and non-ferrous metals; non-metallic materials can be divided into two categories of inorganic materials and organic materials. In mechanical engineering, there are many varieties which are more frequently used.

- Q:Explain why machinery used on a.c supply is usually rated in kVA instead of kW.?

- Because most machinery present an inductive load and so has a less-than-unity power factor. The current peak lags the voltage peak in the two waveforms. However, as the current is drawn at a lower voltage (away from the peak), the load current is higher to get the same overall power to the machine. eg. if it took 20% more current to make up for the voltage phase offset, a 1000W load would be taking the same current as a 1200W load at unity power factor. That's the VA rating, it's equivalent to watts at unity power factor.

- Q:Hello! We are a firm located in Nasik, India. A company from Texas, USA wants to buy 4 of our used machines and transport them to the USA. My questions are:What is the procedure to be followed for this purchase? What all documents or agreements need to be signed? Do we need Law signatures on the purchase agreement both from India and USA or just any one?Your replies are appreciate.

- 1. The question has an Exchange Control angle, apart from other things. The shipping documents have to be rounted through a bank in India(authorised dealer in foreign exchange). Remittance from USA to India will also have to be routed through a bank(authorised dealer in foreign exchange). 2. A bank, being an Authorised Dealer in Foreign Exchange (SBI, BOI, BOB, ICICI Bank, HDFC Bank, etc., etc.) will give necessary guidance in the matter, including the documentation part. 3. Reserve Bank of India has delegated many powers under Foreign Exchange Management Act to Authorised Dealers in Foreign Exchang (banks). 4. Please visit a bank and enquire. .

- Q:he is married to a cuban

- i think i saw him stealing a car down my road last night

- Q:replacement battery and charger for gmc (global machinery company) 18v mag cordless drill?

- === batteries plus === that is your store to buy the replacement ....go to the store or go online and order == describe the old battery well so the order taker gets it right ..... the Global Machinery Company is located in the UK and they build high quali

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

HQJ 90-600 Lightweight concrete wall panel forming machine

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 5 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords