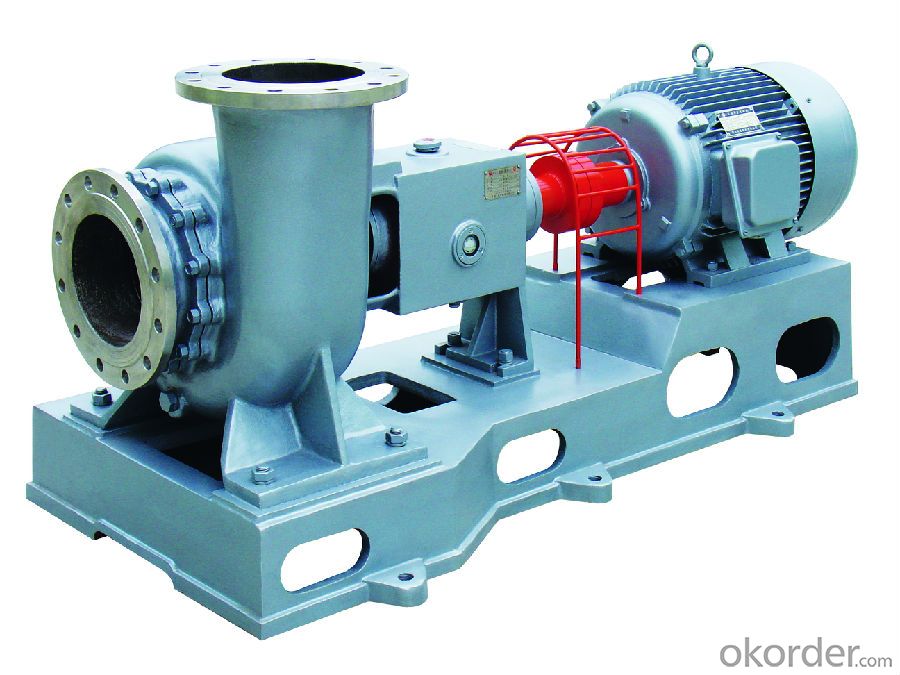

HPY Series Oil Slurry pump as per API610

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 1000 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Description

Conform to API610 standard

Max operating pressure 5.0Mpa

Range of capacity 10~350m3/h

Total head 80~220m

Range of operating temperature -45~450oC

2. Application

Low/high temperature, neutral, corrosive liquid

Industries of petroleum catalytic cracking, coal liquefaction and coal vaporization, synthetic fuel, electric slag plant conveyance etc.

3. Materials

For wetted parts in contact with medium, the common materials are as following,

ZG1Cr13Ni, KmTBCr26, KmTBCr15Mo2

4. Pump Structure

5. FAQ

1 If I increase the power of the motor, must I also increase the power of the inverter?

You must select the size of converter that allows maximum absorption of the electric motor.

2 Do you have pumps with grinders?

Yes, the WQ models.

3 How long is your warranty?

Unless otherwise expressly authorized in writing, by specifying a longer period or different conditions, CNBM states that, for a period of twelve (12) months from delivery date, all Products supplied are free from defects in materials and workmanship, and conform to the applicable specifications. Either the delivery documentation or the invoice must be provided to prove delivery date. In absence of such documents, the production date appearing on the product label may suffice.

- Q:I got my oil changed yesterday and took like a 3 hour drive and back home and had no issues.. today I was at my work visiting and I noticed smoke coming from the engine [sort of more of steam] and a lot of smoke coming from the exhaust. The light on the gauge inside the car for the engine temp isn't working but all the other ones are. A mechanic told me it was a bad water pump, but I just want some more opinions. Or if the oil change could of effected that.. My engine coolant wasn't that low but a greenish liquid was really leaking from underneath the car.

- water pump ,hoses or freezeout plugs,cracked block

- Q:What will the water pump reversal situation?

- The same will reverse pump water, but the head and the pressure greatly reduced, I just finished debugging a pumping station, Stephen multi-stage pump, installation of equipment: multistage water pump motor power 4 75KW 76% head 100 meters, frequency control, motor nameplate nominal current of 143. According to the direction of the motor steering pump mark OK set the start time of 28 seconds after 5HZ boot head start frequency can reach 50 meters (at that time did not install the pressure gauge cannot observe the water pressure of current) in early 118 about 3-5 minutes after the current is reduced to about 97, there are inspection found no problems, suspected pump problems, suspected foot valve not completely open, the reason cannot exclude the end of valve, almost in despair when the thought is not marked in the direction of the pump, re set to restart the current 129.5A to observe that later installed capacity reached 0.55MPa duct pressure gauge head close to the design requirements, the problem on the manufacturer's mark is reverse.

- Q:where is water pump tempertuer sensor in ford focus 2002

- Water-pumps do not have temperature sensors. They're (temperature sensors) always located in the water-jacket of the hottest part of the engine which is the cylinder head. The water-pump coolant temperature is by far the coolest. It's located to the right of the alternator, a few inches facing forward screwed into the cylinder head. The little manual in the glove compartment will not explain where the coolant temperature sensor is.

- Q:1.where is it located and what would I have to remove 1st to get to it. And would I need a torque wrench if so what # would it have to be at when re-installing water pump

- 1990 Toyota Celica

- Q:my marine engine doesnt pump water can you tell me some faults can be thanks vic

- year, make and model. regardless of what it is, most likely answer is the impeller has failed completely because it was not serviced regularly as it should of been. if you were out motoring around and it stalled out before you noticed it, you overheated the engine and it probably needs work for it to run again, if its even repairable. outboard the impeller is located just on top of the lower unit. pretty simple to change, but the exact procedure varies depending on year, make and model. sterndrives can be very similiar and just as easy, or different and even easier. depends on year, make and model. inboards the impeller is belt driven. look for the part dirven by the engine belt(s) with two hoses attached, probably down low on one side.

- Q:What's so good about having a water pump on my stand alone ice maker?What exactly does it do?

- How should the discharge hose be routed to the drain of the ice maker?

- Q:What is the meaning of "ETA" in pump selection table, the unit is%; and what does "NPSH" mean? The unit is m. Is in the south water pump performance curve appeared, please refer to the master, and now thank you.

- Water pump selection table "ETA" is the meaning of efficiency. NPSH refers to the pump's cavitation margin.ETA is abbreviated as "efficient ratio", and Chinese means "water efficiency". The efficiency of the pump here is generally referred to as the efficiency of the pump design point because the actual efficiency of the pump varies with the pump operating conditions. The efficiency of the ETA can also be interpreted as the efficiency of the pump at the rated lift (or rated flow).

- Q:what makes pump come on every 10 seconds when water is on

- Most likely the check-valve is failing to stop flow back to the well. Replace the check valve. It's the metal cylinder just between the pump and the water pipe coming to it from the well.

- Q:I have a leak coming from the water pump that flows down on the side of the AC compressor before landing on the ground. I cannot verify exactly where the leak is coming from on the pump, but I am sure it is the pump leaking because it also sounds bad like rattling. My question is do I have to remove any other components, such as the AC compressor to be able to remove the water pump. I would be great full for any suggestions.Regards,Steph

- 1. Disconnect the Ground Cable. 2. Drain the Coolant. 3. Remove Fan Shroud. 4. Remove Fan Visco Clutch. 5. Remove Radiator Hoses and Thermostat Housing. 6. Remove the Serpentine Belt, pay close attention to the path of the serpentine belt. Suggestion draw a diagram as to it's path, before removing. 7. Remove the Water Pump Pulley and Power Steering Pulley. 8. Remove the Tension Adjuster Mechanism. 9. Loosen the Power Steering Pump and move it to the right a little. 10. Remove the Water Pump, and you're done. Tools Needed .... A nice Stereo, plenty of Beer, and a couple of friends to keep you company. Good Luck !

- Q:need step by step on how to change water pump

- steps okorder /

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

HPY Series Oil Slurry pump as per API610

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 1000 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords