Household Foil Household Foils Using Aluminum Foils

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3 m.t.

- Supply Capability:

- 300 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Description:

Aluminium foil (or aluminum foil) is aluminium prepared in thin metal leaves with a thickness less than 0.2 millimetres (8 mils); thinner gauges down to 6 micrometres (0.24 mils) are also commonly used.In the United States, foils are commonly gauged in thousandths of an inch or mils. Standard household foil is typically 0.016 mm (0.63 mils) thick, and heavy duty household foil is typically 0.024 mm (0.94 mils). Thefoil is pliable, and can be readily bent or wrapped around objects. Thin foils are fragile and are sometimeslaminated to other materials such as plastics or paper to make them more useful. Aluminium foil supplantedtin foil in the mid 20th century.

2.Why you choose us?

Our quotation is more attractive!

3.Specification

Annual production of aluminium foil was approximately 800,000 tonnes (880,000 tons) in Europe and 600,000 tonnes (660,000 tons) in the U.S. in 2003. Approximately 75% of aluminium foil is used for packaging offoods, cosmetics, and chemical products, and 25% used for industrial applications (e.g. thermal insulation, cables and electronics).

Household Foil Household Foils Using ALUMINIUM

Application: Household packages

Alloy: 8011/ 1235

Temper: 0.009mm-0.04mm (±6%)

Width: 200mm-720mm

Mechanical Properties: Tensile Strength (U.T.S)≥ 50Mpa, Elongation≥ 1%

Standard: GB/ T3198 / ASTM-B209/EN 546

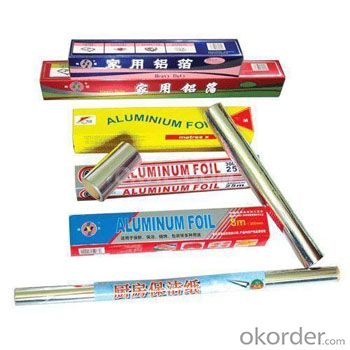

4.Pictures:

5.FAQ:

1)What's kind of payment term we can supply?

CIF,CFR, FOB and other.

2)Can we supply samples?

Yes, we can!

3)What can you do if you have other quastions?

You can contact us freely at any time!

- Q:They said something about ironing it with aluminum foil on the design before washing it.? and wash it inside out in cold water.? Does this sound right.? Also how do I dry it.?

- isopropyl alcohol and coarse grain saltstick it in a ziplock and shake it upIfyou want to keep your rez though,scrape it out with a small pointy object

- Q:Hi, I work at a gas station and people come in to buy all these at the same time.I suspect that they are used to make some time of illegal drugs, does anyone know what?

- Pompero is a very soft yarn made from 30% new wool, 50% acrylic and 20% polyamidePatterns for this yarn can be found in Patons Leaflet 3733, Leaflet 3734, and Booklet 3782This yarn is discontinuedRecommended Needles: 5.50mm Tension: 16 sts, 22 rows, 10cmBall size: 50g, approx 75mMachine washable So, now find another yarn with the same tension (gauge) and length of yarn.

- Q:I have a friend who wants to bake someYou basically pre heat the oven to 250 degrees and then add marijuana in a aluminum bowl for 15 min to crumble it upThen sprinkle on nutella covered crackers and cover the crackers in aluminum foil and then put in the oven for 20 min at 300 degreesMy friend wants to know will it smell up the oven and the houseHe can't let his parents find outHe would only be using around .3 grams of marijuanaAnd would hve a couple hours to air it outWill the house and oven smell really bad of weed or will it not smell, or smell a bit then go away a little while later???

- UmyeahThe entire house will reek of it for a long time, even with the windows openPlus, it will be nasty! Just smoke it, or infuse some oil for brownies.

- Q:My husband seems to think if we leave extra food out, my grown cat will be okayI'm worried because his litter box is cleaned daily and I'm afraid that he may get into somethingWe have never left him alone for so longI went ahead and scheduled him to board him with my other pets but my husband thinks it's not necessaryWhat do you think? Am I just a worry-wort?

- I'm gonna list some stuff from my iPod.I've got a lot more than this but I'm sure you don't want to be too overwhelmedAdelitas Way (Invincible, Last Stand) AFI (Medicate, Miss Murder) Apocalyptica (I Don't Care, Not Strong Enough) Bullet For My Valentine (Your Betrayal, All These Things I Hate) Deepfield (Don't Let Go, Nothing Left To Lose) Deftones (Change, Minerva) Five Finger Death Punch (Bad Company, Coming Down) Hoobastank (Crawling In The Dark, Out Of Control) Jimmy Eat World (Pain, Bleed American) Korn (Coming Undone, Get Up) I'm gonna stop here, but that should be enough to start withGood luck! EDIT: By overwhelmed, I mean that I'm sure you'll be spending enough time looking up what other people have also suggested so I don't want to put too many moreYou might want to try making a Pandora station, by the way.

- Q:I'm 18 and leaving for the Coast Guard at the end of this summerBefore that though my father is handing down his 12 ft aluminum starcraftIt has a 8 hp evinrude motor on it and I want to purchase an electric motorCould I have some guidance on how to or maybe some suggestions on a good budget electric (trolling) motor?

- Mosaic Tile Table Top

- Q:HiWhen I used to send money orders or cash in the mail I usually sent them with foil wrapped around them in an envelope, but I was recently told to stop doing that because the post office might think I was trying to send anthrax samples in the mail? What does anthrax have to do with wrapping things in an envelope with foil?I can simply cover cash or money orders with paper, a few sheets, so people can't see the cash or the money order in the envelope when they hold the envelope up to the light, which is what I usually do anyway.Please help- thank you.

- HiThis one is awesome and relatively easyBrown a pound or so of ground beef with onion, green peppers, one clove of garlic minced, and salt and pepper to tasteWhen brown, drain grease and add 1 small can tomato paste and 1 large can diced tomatoesGet that all stirred up then add about a teaspoon of Italian SeasoningLet that simmer for about 15 minutes, and you have your sauceTo prepare the noodles, put about twelve of them into boiling water with a dash of salt and about a tablespoon of oil in itIf they don't fit into the pan, it's okay, they will get soft quickly and you can then manipulate them into the panWhen they are done, drain them and rinse them with cold water to prevent them from sticking together Then, you take your pan(For this recipe, use a 9 by 13) Put half the noodles in the bottom after spraying with PAMthen, you take a tub of ricotta cheese (not cottage cheese, it is runny and gross) and mix it with an eggput half the ricotta cheese on top of the noodles (I use a spoon and spread it because it is a little tricky)Then put half of a one pound package of shredded mozzarella cheese on top of thatThen put half of your sauceSprinkle the top with a good amount of grated Parmesan, some Italian seasoning, salt, and pepperCover this layer with the rest of the noodlesIf the noodles are too long, on the first layer let them go up the sides, but on the second layer you need to cut them to fitThen, put on the rest of the ricotta mixture, the rest of the mozzarella, then the rest of the sauceThen sprinkle the top with a liberal amount of parmesan, and some Italian seasoning, salt, and pepper Then put in a 350 oven for about a half an hour, or until everything is really bubblyServe with some good garlic bread and a tossed saladAfter assembly and before baking, you can store the lasagna in the fridge for a day or so if necessary, and many cooks feel this actually enhances the flavor of the lasagna.

- Q:I am holding a bake sale to raise $ for the American Cancer Society on Saturday 6/15I am planning on baking cookies for itHow long can they keep for? Is it possible to freeze them, or will that impact the taste?

- Store each type of cookie separately in air tight containers or Ziploc bagsCrisp cookies can become soft if stored with soft cookies and mixing cookie varieties can also cause the cookies to take on the flavor of other cookiesStore delicate cookies like shortbread , spritz etcin airtight containers and separate cookie layers with waxed paperMost unfrosted cookies will fine at room temperature for 3 daysHowever, keep cookies with cream cheese frosting (such as pumpkin bars) in the fridge for up to a week Cookies may be stored in the freezer for 3 to 4 months if wrapped in heavy-duty aluminum foil and then placed in heavy-duty freezer bags To recrisp cookies, preheat oven to 300°FBake 5 minutesCool on wire rack.

- Q:An element has 3 valence electrons in 3rd shellName the element and give its atomic number.?

- Aluminum has 3 electrons in its 3rd shell and atomic number 13 Hope this Helps! :D

- Q:I adopted a 10 week old kitten back in JulyHe was a tiny little thing and cute as can beNow he's a BIG HOLY TERRORHis two favorite games are playing with the slat of the metal mini blinds in the MIDDLE OF THE NIGHT and sitting in the window when my two, very large dobermans are outside to torment themThey try to get him through the window and I'm afraid they are going to break the glassI've taken to leaving the mini blinds raised all of the time just so he won't be able to paw at the slats and make noise, but I CANNOT keep him out of the window sillI've tried everythingEven spraying him with water in a spray bottle, but he LIKES it! Nothing worksHow in the HECK do you train a cat?! I'm a dog person, my boyfriend is the cat personThe cat makes me so mad sometimes that I want to scream, then he comes up to me purring, and rubs against me, and he's so cute that I forget I was mad at himI know how to train dogs, I have experience with themCats are WAY outside of my area of expertiseCan somebody help me?

- similar questions here before, put aluminium foil on the sill, that irritates their feet you could put fly paper down, I bet he won't try that twice my favorite would be strips of thumbtacks.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Household Foil Household Foils Using Aluminum Foils

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3 m.t.

- Supply Capability:

- 300 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords