Hot selling pp non woven fabric (TNT) with good price

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 kg

- Supply Capability:

- 10000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

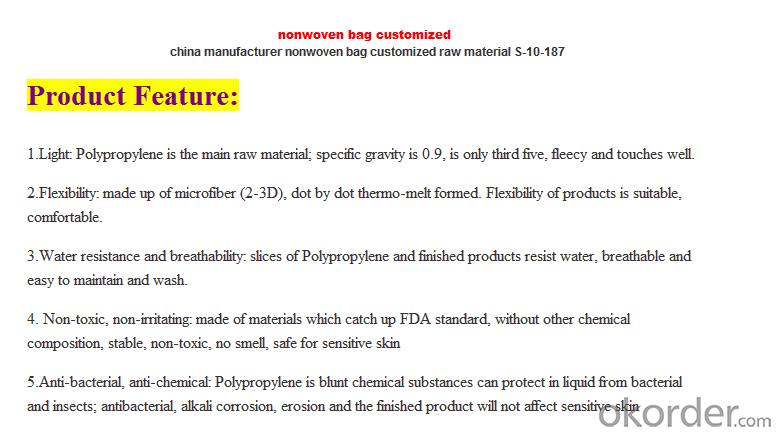

We are recognized as a reliable Manufacturer, Exporter and Supplier of Non Woven Fabric. We can provide Non Woven Fabric in any gram/m2 and any colour required by customer. Non Woven Fabrics are broadly defined as sheet or web structures bonded together by entangling fiber or filaments (and by perforating films) mechanically, thermally or chemically. PP Spun bonded Non woven Fabrics are produced using a precise extrusion-based technology. The polymer is stretched into a continuous filament and loosely spread onto a conveyor belt to form the web. Air is used to form and lay the fabric filaments. On the other hand, some non woven fabrics can be recycled after use, given the proper treatment and facilities.

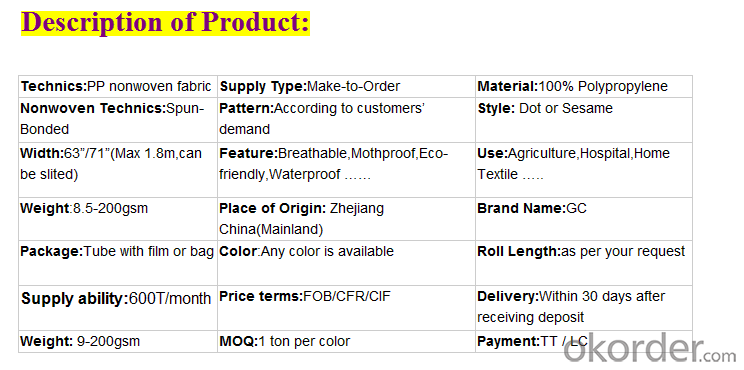

Product Specifications

Weight: 10 - 150 gsm

Width: Max 1600 mm (can be slit)

Fabric Roll Length: As per buyer’s need ( 200 - 1200 Mtr)

Color: various colors available.

Procedure of production: Spun bonded Non Woven, Diamond design

Material: polypropylene

Minimum Order: 1000 Kg

Sample: sample free, freight collect

Product Application

Non woven fabric manufacturers usually manufacture the fabric in a roll form. It is then sent to various other industries where it has end applications, where is it cut and given different form depending upon the use. They can also be used in combination with different materials and offer a wide range of products.

Colored Non woven fabrics are use in many sectors and variety of applications, such as Health, Hygiene, Medical, Packaging, Agriculture, Furniture Upholstery, Geo Textiles, Leather Industry, Shoes and Garments. Customers come from the textile and automotive industries as well as many other sectors.

- Q:How to make fibrous textiles for waste plastic bottles?

- Plastic bottle is a treasure, you can also make quilts, sofas, mattresses and other home textiles fillers, can also be used to make carpets, imitation and down products

- Q:Textile and garment industry, including a complete industrial chain which

- Clothing, refers to the clothing shoes and bags of toys, such as the general term, more fingers clothes. Clothing in the early development of human society has emerged, the ancient people can find a variety of materials around the rough "clothes" to protect the body

- Q:What are the invoices for the textile industry?

- If you are not a general taxpayer, the invoice you made when you purchased it is only an ordinary invoice, not an invoice, an invoice is invariably speaking for the general taxpayer, but some people are accustomed to buying materials or The invoice for the goods is called the invoice.

- Q:From the yarn to the finished textile fabric production process is how

- Fabric mercerizing: refers to the cotton fabric in the case of tension, after the treatment of concentrated caustic soda, so that fabric gloss better, more crisp, better shape. Commonly known as double mercerizing fabric complete process: cotton spinning → combing → yarn singeing → yarn mercerizing → yarn twisted → fixed color, soft, twisted after the formation of mercerized cotton yarn → yarn forming the fabric → fabric dyeing (if the early yarn is not dyed) → fabric mercerizing → fabric pre-shrink, stereotypes → the formation of double mercerized cotton fabric, cloth can be clothing

- Q:What is the meaning of the number of yarns used in cotton textiles?

- The fineness of the yarn (in English): refers to a pound (454 grams) of heavy cotton yarn in the provisions of moisture regain, there are several 840 yards (1 yards = 0.941 meters) long, that is, a few miles of yarn, As "a few yarn", the unit with "S" said.

- Q:What is the number of raw materials for textile enterprises?

- Generally based on the variety of cloth, cloth type, speed and other parameters, in order to determine the sizing rate, slurry type

- Q:How to grow in the textile industry and have their own customers

- Third, the loss of each process. Like 1000KG raw cotton, spinning to wear about 10%, dyeing yarn to wear about 8%, weaving to about 2% loss, finishing if the dyeing loss to about 8%

- Q:What is the earliest textile tool?

- Pre-Qin's textile has been liberated from the "hand refers to the hook". ("Yellow Emperor" and "Huainanzi" records "hand refers to the hook" refers to a root yarn in turn connected to the same root on the stick, the other end is followed by another stick in the above

- Q:Buy two large round machine to do processing, in Changshu side of the textile processing to do it?

- Changshu's overall strength is good. Textile industry more, there is the strength of the points, the goods will be the merits of the points. So Changshu market is more chaotic, good expensive, there are also defective defective.

- Q:What is the anti-perspiration finishing of textiles?

- Many manufacturers put the anti-perspiration requirements made single-parent single defense fabric, in a sense is to complete the customer's request, but the requirements of high customers, only single-parent single effect is unable to meet the requirements, be sure to do Perspiration requirements.Hope to help you, if you want to do further understanding, see my account name and contact me

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Hot selling pp non woven fabric (TNT) with good price

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 kg

- Supply Capability:

- 10000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches