Hot Sale Smart Cement Semi Trailer with Good Quality

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 100 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

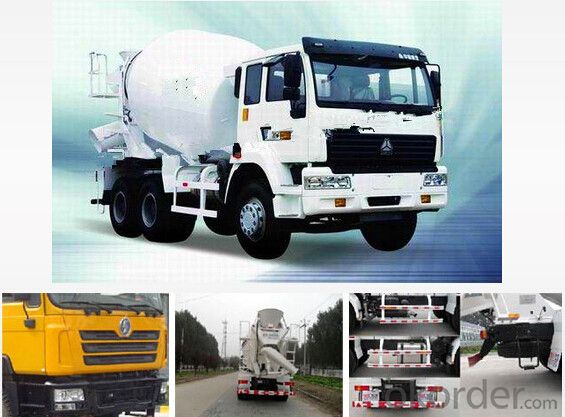

Product Name: Hot Sale Smart Cement Semi Trailer with Good Quality

1. Specification

Model: ZJV9409GFLLY | |

Overall size (mm) | 12991(L)*2500(W)*3995 (H) |

Wheel base (mm) | 8168+1310+1310 |

Tread (mm) | 1850 |

Kerb mass(Kg) | 11610 |

Min. turning diameter(m) | 24 |

Min. ground clearance | 360 |

Main configuration parameters | |

Axles | Fuhua brand,16T , 3 axles |

Towing pin | Baohua brand, 50mm or 90mm |

suspension | Leaf spring suspension |

tyre | 12.00R20, 12+1 |

Brake system | dual circuit, drum brake, air drive with ABS |

ABS | 4S/2M |

Tank body parameter | |

Tank actual volume��m3�� | 58 |

Tank actual dimension(mm) | 12040*2500 |

Unloading speed | More than or equal to 1.2m3/min |

Discharge residue rate | Less than 0.3% |

Rated pressure(Mpa) | 0.2 |

Tank mouth | Two compartment with two tank mouth |

Air compressor | 10.0m³/min |

Diesel engine | Weichai 4100 |

2. Application

Cement semi trailer

3. Package

Put into containers.

FAQ:

Q1: Why buy Materials & Equipment from OKorder.com?

A1: All products have its ISO certifications, adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

Q3: How soon can we receive the product after purchase?

A3: Within three days of placing an order, we will begin production. The specific shipping date is dependent upon international and government factors, but is typically 10 to 30 workdays.

Q4: If we can produce Hot Sale Smart Cement Semi Trailer with Good Quality according to customers request?

A4: Yes, we can produce Hot Sale Smart Cement Semi Trailer with Good Quality according to the difference country situations to make it suitable to the market and customers. We have very professional technical team to make the design.

Q5: How to make a quick resolution for after service?

A5: We have overseas branches all-around of world, If needed, the seller shall dispatch 2 engineers to the buyer's site for supervision of training. The buyer shall make available of necessary facilities &skilled personnel at site for training.

- Q:What is the driving license for a concrete mixer truck?

- B2, you can do it directly. But it must be 21 years old and must be taught in permanent residence. The temporary residence is limited to the C series. The tuition fee for Beijing is 2,800 to 3100.

- Q:What is the meaning of the word "concrete" in the concrete mixer jar?

- The "concrete" means "concrete" means "concrete". This is not to say that the car must print these two words, depending on the company. But I know the name of the company and the company.

- Q:Does it affect the ease of mixing too long?

- The site stirring, the quality is not easy to control, the site pollution is serious for the main reason, the construction committee has the file request, so all do not stir in the scene.

- Q:What can be done to remove the concrete from the concrete mixer truck

- This is the worst case scenario, you don't have to think about it, just change the tank, don't think about how you can save the money. It's a big lesson.

- Q:How many cubic meters of concrete mixer transport vehicle

- Existing 3 cubic concrete mixer truck, 3.5 cubic, 4 cubic, 5 cubic, 6 cubic, 8 cubic, 9 12 cubic cubic, 10 cubic, such as specifications, can meet the different needs of customers, chassis choose well-known brands at home and abroad, oil pump, hydraulic motor, deceleration pause with American Eaton, the Italian state, and other well-known brands at home and abroad, to ensure that the vehicle performance is stable, safe and reliable.

- Q:What is the car for concrete

- It is called mixer truck concrete mixer truck There are also some people called muck mixer truck

- Q:What is the difference between a concrete mixer and a tanker?

- Concrete mixers are also called concrete mixers, and they are called concrete transporters, which are actually a kind of thing.

- Q:How many cars do you have for a concrete tanker

- Now the concrete agitator truck is generally measured in the quantity of tank, usually from six square cans to 18 cans, and now it is commonly used in 10-15 cans.

- Q:How does the concrete mixing truck work?

- Working principle is that by taking power device to take out car chassis power, and drive hydraulic system of the variable pump, the mechanical energy into hydraulic energy to quantitative motor, motor and drive reducer, driven by speed reducer mixing plant, for mixing concrete

- Q:Is a tanker and a mixer a thing

- Usually a concrete mixer is called a tanker But the tanker also has a concrete factory that transports the bulk cement, and USES the long can to drag the engine

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Hot Sale Smart Cement Semi Trailer with Good Quality

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 100 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords