Hot Sale Polypropylene Spun-boonded Garment Interlining Non Woven Fabric

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 kg

- Supply Capability:

- 10000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

We are recognized as a reliable Manufacturer, Exporter and Supplier of Non Woven Fabric. We can provide Non Woven Fabric in any gram/m2 and any colour required by customer. Non Woven Fabrics are broadly defined as sheet or web structures bonded together by entangling fiber or filaments (and by perforating films) mechanically, thermally or chemically. PP Spun bonded Non woven Fabrics are produced using a precise extrusion-based technology. The polymer is stretched into a continuous filament and loosely spread onto a conveyor belt to form the web. Air is used to form and lay the fabric filaments. On the other hand, some non woven fabrics can be recycled after use, given the proper treatment and facilities.

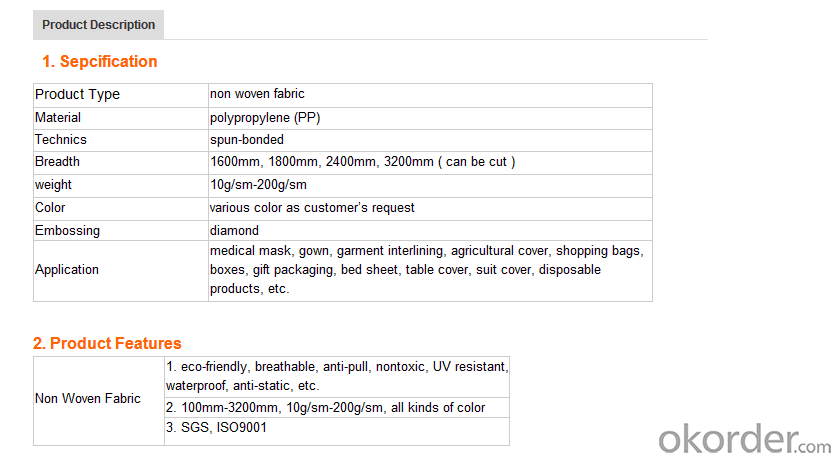

Product Specifications

Weight: 10 - 150 gsm

Width: Max 1600 mm (can be slit)

Fabric Roll Length: As per buyer’s need ( 200 - 1200 Mtr)

Color: various colors available.

Procedure of production: Spun bonded Non Woven, Diamond design

Material: polypropylene

Minimum Order: 1000 Kg

Sample: sample free, freight collect

Product Application

Non woven fabric manufacturers usually manufacture the fabric in a roll form. It is then sent to various other industries where it has end applications, where is it cut and given different form depending upon the use. They can also be used in combination with different materials and offer a wide range of products.

Colored Non woven fabrics are use in many sectors and variety of applications, such as Health, Hygiene, Medical, Packaging, Agriculture, Furniture Upholstery, Geo Textiles, Leather Industry, Shoes and Garments. Customers come from the textile and automotive industries as well as many other sectors.

- Q:How to make fibrous textiles for waste plastic bottles?

- T-shirts made from recycled plastic bottles. This T-shirt is made of five 500 ml plastic bottles, and then some cotton fiber

- Q:Textile raw materials of mineral fiber

- The main ingredient is inorganic, also known as natural inorganic fibers, inorganic metal silicates, such as asbestos fibers.

- Q:DTY FDY POY What are the textile raw materials?

- FDY: full stretch silk. Full name: FULL DRAW YARN. The synthetic filament filaments were further prepared by spinning. The fibers have been fully stretched and can be used directly for textile processing.

- Q:Is there a large yarn factory or a textile garment factory?

- Textile: the subject is too large, including textile raw materials production, spinning, weaving, printing and dyeing, finishing, and then into the clothing link.

- Q:How to detect formaldehyde content of textiles?

- For example, textile dyeing process, in order to improve the color fastness, the need for color processing, commonly used cationic resin fixing agent Y and fixing agent M, they are dicyandiamide and formaldehyde condensate, containing a high free formaldehyde.

- Q:What is the role of textile degreasing in life?

- Clothing in the dyeing and finishing process, often encountered in the cloth oil, stains, color stains, color flowers, silicone oil spots, etc., constitute a low amount of product resources, and some even helpless repair, and in the process of processing need Use a lot of additives, so clothing is also very easy to become very oil. At this time, you need to deal with the textile degreasing agent.

- Q:How to grow in the textile industry and have their own customers

- Third, the loss of each process. Like 1000KG raw cotton, spinning to wear about 10%, dyeing yarn to wear about 8%, weaving to about 2% loss, finishing if the dyeing loss to about 8%

- Q:Antistatic fabrics of textile electrostatic materials

- It has long been found that when the two insulators are rubbed and separated from each other, the dielectric coefficient, the higher object is positively charged, and the dielectric coefficient is low with a negative charge. This is the law found at the end of the nineteenth century, and this rule is consistent with many experimental results

- Q:Buy two large round machine to do processing, in Changshu side of the textile processing to do it?

- Changshu's overall strength is good. Textile industry more, there is the strength of the points, the goods will be the merits of the points. So Changshu market is more chaotic, good expensive, there are also defective defective.

- Q:What is the imo standard in the textile industry?

- The purpose of the Global Organic Textiles Standard is to ensure that textile fabrics and garments of textiles manufacturers are certified and recognized in all major world markets as an important step towards harmonization and transparency of textile marks.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Hot Sale Polypropylene Spun-boonded Garment Interlining Non Woven Fabric

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 kg

- Supply Capability:

- 10000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products