Hot Rolled SUP10 Spring Steel Bar,Round Bar

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 30 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

Hot Rolled SUP10 Spring Steel Bar,Round Bar

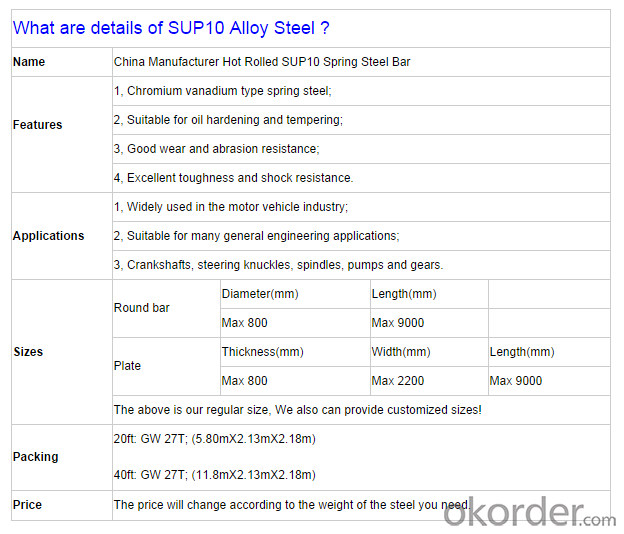

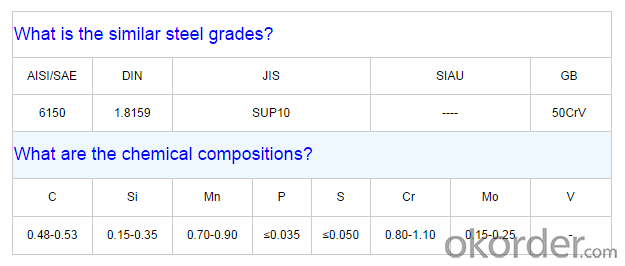

Product information:

Product show

Workshop show

Our service:

- Q:Cold drawn steel wire is a round bar or thread steel in Construction Engineering?

- Cold drawn steel wire belongs to round bar in building engineering, and it is thread steel after coining. But the material of steel is not good. Who knows what material he made?.

- Q:How many tons of pressure can the round steel of 70 inches bear?

- If the steel will generally approximate compressive strength considering tensile strength, even if is only 4 tons / square centimeters, each round cross section of 26 mm diameter is 5.3 cm, maximum 5.3*4 about 20 tons of pressure, the actual use should take into account the safety factor;

- Q:Are steel and round steel the same thing?

- Yuan steel and round steel are the same thing, they are round steel.

- Q:What are the advantages of using spring steel round bars?

- Spring steel round bars have numerous advantages: 1. Exceptional strength: Known for their high strength, these round bars can withstand extreme stress and strain. They are perfect for applications that require durable and strong materials. 2. Remarkable flexibility: These round bars are incredibly flexible and can be easily shaped, bent, or formed without losing their strength. This quality makes them suitable for a wide range of manufacturing processes. 3. Superior elasticity: With excellent elasticity, these round bars can return to their original shape after being deformed or stressed. This elasticity is crucial for applications that require shock or vibration absorption. 4. Fatigue resistance: These round bars are highly resistant to fatigue and can endure repeated cycles of loading and unloading without losing their mechanical properties. This reliability and longevity make them ideal for demanding applications. 5. Exceptional toughness: Spring steel round bars exhibit outstanding toughness, enabling them to withstand sudden impacts or heavy loads without breaking or fracturing. They are perfect for harsh environments or heavy-duty operations. 6. Corrosion resistance: Many spring steel round bars are made from corrosion-resistant alloys, protecting them against rust and other forms of corrosion. They are ideal for applications where moisture or corrosive substances are present. 7. Cost-effective: Compared to other types of steel or materials, spring steel round bars offer a cost-effective solution. Their durability and longevity reduce the need for frequent replacements, resulting in long-term cost savings. In conclusion, spring steel round bars have numerous advantages, including high strength, flexibility, superior elasticity, resistance to fatigue, exceptional toughness, corrosion resistance, and cost-effectiveness. These properties make them a preferred choice in various industries such as automotive, construction, manufacturing, and aerospace.

- Q:Are steel round bars suitable for machining operations?

- Yes, steel round bars are suitable for machining operations. They have excellent machinability due to their uniform shape and consistent mechanical properties, which make them easy to cut, drill, and shape into various components.

- Q:What are the different alloying elements used in steel round bars?

- The different alloying elements commonly used in steel round bars include carbon, manganese, silicon, sulfur, phosphorus, chromium, nickel, molybdenum, vanadium, and sometimes tungsten. These elements are added in varying quantities to enhance specific properties of the steel, such as strength, corrosion resistance, and heat resistance.

- Q:Is round steel round steel?

- Round steel is a solid strip of steel whose cross section is round. The specifications are expressed in millimeters of diameter, such as "50", which means a round bar of 50 millimeters in diameter.

- Q:What are the different specifications for steel round bars?

- There are several specifications that are used to describe steel round bars. These specifications include the diameter, length, tolerance, and grade of the steel used. The diameter of a steel round bar is a key specification, as it determines the size of the bar. Common diameters range from 1/4 inch to 12 inches, with various increments in between. The diameter is usually measured across the widest point of the bar. The length of a steel round bar refers to its overall size from end to end. Standard lengths range from 10 to 20 feet, although custom lengths can also be obtained. The length is an important factor to consider when determining the quantity needed for a specific project. Tolerance is another specification that describes the allowable deviation from the specified diameter or length. It ensures that the steel round bar meets the required dimensions and can be used effectively. Tolerance values are typically expressed in plus or minus values, such as +/- 0.005 inches. The grade of steel used in round bars is also specified, indicating the quality and strength of the material. Common grades include carbon steel, alloy steel, stainless steel, and tool steel. Each grade has its own unique properties and is suitable for different applications based on the desired strength, corrosion resistance, and machinability. In addition to these specifications, other factors such as surface finish and heat treatment may also be specified depending on the intended use of the steel round bars. These specifications ensure that the steel meets the necessary requirements for a particular application, whether it be in construction, manufacturing, or other industries.

- Q:What are the advantages of using precipitation-hardening steel round bars?

- There are several advantages of using precipitation-hardening steel round bars. Firstly, these bars offer high strength and toughness, making them suitable for applications that require heavy load-bearing capacity. Secondly, they have excellent corrosion resistance, making them ideal for use in harsh environments or exposed to corrosive elements. Additionally, precipitation-hardening steel round bars can be easily machined and formed into various shapes, providing versatility in design and manufacturing. Lastly, these bars possess good dimensional stability, ensuring consistent performance and reliable results in critical applications.

- Q:What are the advantages of using mild steel round bars?

- Using mild steel round bars in various applications offers several advantages. To begin with, mild steel round bars exhibit exceptional strength and durability. They have the capacity to withstand high levels of stress and pressure, rendering them suitable for use in construction, manufacturing, and engineering ventures. The robustness of mild steel round bars ensures that they do not readily deform or fracture under heavy loads, providing a dependable and long-lasting solution. Furthermore, mild steel round bars possess favorable weldability. They can be easily joined or affixed to other materials through welding, granting them versatility across different applications. This allows for effortless customization and flexibility in design, as the bars can be shaped and connected to form intricate structures or components. In addition, mild steel round bars feature a low carbon content, making them more cost-effective in comparison to alternative steel types. They are readily available and affordable, making them a popular choice within various industries. Moreover, mild steel round bars exhibit excellent machinability. They can be effortlessly cut, drilled, and shaped using common machining techniques, facilitating easy fabrication and customization. This renders them suitable for a wide array of applications, ranging from construction to automotive components. Lastly, mild steel round bars offer commendable corrosion resistance. Although they may not possess the same level of corrosion resistance as stainless steel, they still provide adequate protection against rust and other forms of corrosion. This renders them suitable for outdoor applications or environments with high levels of humidity or exposure to moisture. In conclusion, the advantages of utilizing mild steel round bars include their exceptional strength and durability, favorable weldability, cost-effectiveness, machinability, and corrosion resistance. These factors make them a reliable and versatile choice for various industrial and construction applications.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Hot Rolled SUP10 Spring Steel Bar,Round Bar

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 30 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

New products

Hot products

Related keywords