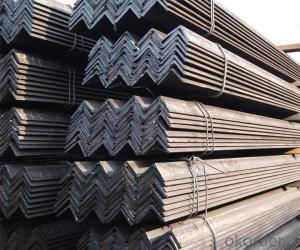

Hot Rolled Steel Unequal Angle Steel Good Price SS400 Competitive Price

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 35000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

OKorder is offering Hot Rolled Steel Unequal Angle Steel Good Price SS400 Competitive Price at great prices with worldwide shipping. Our supplier is a world-class manufacturer of steel, with our products utilized the world over. OKorder annually supplies products to European, North American and Asian markets. We provide quotations within 24 hours of receiving an inquiry and guarantee competitive prices.

Product Applications:

Hot Rolled Steel Unequal Angle Steel Good Price SS400 Competitive Price are ideal for structural applications and are widely used in the construction of buildings and bridges, and the manufacturing, petrochemical, and transportation industries.

Product Advantages:

OKorder's Hot Rolled Steel Unequal Angle Steel Good Price SS400 Competitive Price are durable, strong, and resist corrosion.

Main Product Features:

· Premium quality

· Prompt delivery & seaworthy packing (30 days after receiving deposit)

· Corrosion resistance

· Can be recycled and reused

· Mill test certification

· Professional Service

· Competitive pricing

Product Specifications:

Specifications of Angle Steel

1. Invoicing on theoretical weight or actual weight as customer request.

2. Length: 6m, 9m, 12m.

3. Sizes:

Size(mm) | Mass(Kg/m) | Size(mm) | Mass(Kg/m) |

50*50*4 | 3.059 | 63*63*5 | 4.822 |

50*50*5 | 3.77 | 63*63*6 | 5.721 |

50*50*6 | 4.465 | | |

Payment terms:

1).100% irrevocable L/C at sight.

2).30% T/T prepaid and the balance against the copy of B/L.

3).30% T/T prepaid and the balance against L/C.

Packaging & Delivery of Hot Rolled Steel Unequal Angle Steel Good Price SS400 Competitive Price

1. Packing: it is nude packed in bundles by steel wire rod

2. Bundle weight: not more than 3.5MT for bulk vessel; less than 3 MT for container load

3. Marks:

Color marking: There will be color marking on both end of the bundle for the cargo delivered by bulk vessel. That makes it easily to distinguish at the destination port.

Tag mark: there will be tag mark tied up on the bundles. The information usually including supplier logo and name, product name, made in China, shipping marks and other information request by the customer.

If loading by container the marking is not needed, but we will prepare it as customer request.

4. Transportation: the goods are delivered by truck from mill to loading port, the maximum quantity can be loaded is around 40MTs by each truck. If the order quantity cannot reach the full truck loaded, the transportation cost per ton will be little higher than full load.

5. Delivered by container or bulk vessel

FAQ:

Q1: Why buy Materials & Equipment from OKorder.com?

A1: All products offered byOKorder.com are carefully selected from China's most reliable manufacturing enterprises. Through its ISO certifications, OKorder.com adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

Q3: How soon can we receive the product after purchase?

A3: Within three days of placing an order, we will begin production. The specific shipping date is dependent upon international and government factors, but is typically 7 to 10 workdays.

Q4: What makes stainless steel stainless?

A4: Stainless steel must contain at least 10.5 % chromium. It is this element that reacts with the oxygen in the air to form a complex chrome-oxide surface layer that is invisible but strong enough to prevent further oxygen from "staining" (rusting) the surface. Higher levels of chromium and the addition of other alloying elements such as nickel and molybdenum enhance this surface layer and improve the corrosion resistance of the stainless material.

Q5: Can stainless steel rust?

A5: Stainless does not "rust" as you think of regular steel rusting with a red oxide on the surface that flakes off. If you see red rust it is probably due to some iron particles that have contaminated the surface of the stainless steel and it is these iron particles that are rusting. Look at the source of the rusting and see if you can remove it from the surface.

Images:

- Q:Can steel angles be used for framing partitions and walls?

- Yes, steel angles can be used for framing partitions and walls. Steel angles are commonly used in construction for their strength and durability. They can be used to create a framework for partitions and walls by providing structural support and stability. Steel angles are versatile and can be easily cut and welded to fit the desired dimensions and angles. They are also resistant to fire, pests, and moisture, making them a suitable choice for framing interior walls and partitions in both commercial and residential buildings.

- Q:What is the angle iron back machine?

- In the structure of angle steel tower, a large number of iron fittings are used. In order to make the connection tight, it is necessary to shovel or clean the angle iron of the iron connecting piece, and the NC angle steel back shovel is just for the purpose of cleaning the angle iron. For more detailed information, you can look at the super CNC website, they are professional manufacturers.

- Q:Can steel angles be used for playground equipment?

- Yes, steel angles can be used for playground equipment. Steel angles are commonly used for constructing various playground structures such as slides, climbing frames, and swing sets due to their durability, strength, and ability to withstand heavy use and outdoor elements.

- Q:How do steel angles perform under wind loads?

- Structural support and stability are provided by steel angles commonly used in construction. The reliability and effectiveness of steel angles in withstanding wind loads have been proven. The shape and design of steel angles enable them to resist the force exerted by wind, preventing any notable deformation or failure. Under wind loads, the force is evenly distributed along the length of steel angles, transferring it to other connected structural elements. This minimizes the potential for localized stress concentrations and guarantees the overall stability of the structure. Steel angles possess high strength and stiffness, enabling them to resist bending and twisting forces caused by wind. This is especially crucial in areas prone to high wind speeds or in tall buildings where wind loads can be more substantial. The rigidity of steel angles ensures the structure's integrity and prevents excessive deflection or deformation. Additionally, steel angles can be easily connected to other structural components using various methods such as welding, bolting, or riveting. This allows for a secure and reliable connection that can endure wind loads without compromising the overall strength and stability of the structure. To summarize, steel angles excel under wind loads due to their shape, strength, and rigidity. They efficiently distribute wind forces and maintain structural stability, making them a dependable choice for construction projects in wind-prone areas or for structures requiring significant wind load resistance.

- Q:Can steel angles be cold-formed or bent to specific shapes?

- Yes, steel angles can be cold-formed or bent to specific shapes. Cold forming is the process of reshaping a metal without the use of heat, typically through methods such as bending, rolling, or pressing. Steel angles, which are L-shaped structural components made of steel, can be cold-formed to achieve various shapes and angles as per the specific requirements of a project. This process involves applying force and pressure to the steel angle, causing it to deform and take on the desired shape. Cold forming steel angles allows for flexibility in design and customization while maintaining the strength and durability of the steel.

- Q:Can steel angles be used in earthquake-resistant building designs?

- Indeed, earthquake-resistant building designs can incorporate the usage of steel angles. Steel, renowned for its exceptional strength and ductility, proves to be a suitable material for constructing earthquake-resistant structures. In various applications, steel angles, also referred to as L-shaped steel sections, can be employed to provide structural support and reinforcement. One of the primary benefits of incorporating steel angles into earthquake-resistant building designs lies in their capacity to withstand lateral loads and shear forces. The L-shape of these steel angles establishes a robust and stable connection between distinct structural components, effectively distributing and transferring loads during seismic events. Consequently, this aids in mitigating structural deformation and averting collapse. Additionally, the fabrication and installation of steel angles are exceptionally convenient, rendering them a favorable choice for earthquake-resistant designs. These angles can be welded, bolted, or riveted to other steel elements, ensuring a sturdy and dependable connection. Furthermore, customization options are available, allowing for structural configurations to be tailored to meet specific design requirements. Furthermore, steel angles exhibit commendable fire resistance properties, a crucial aspect to consider in earthquake-resistant designs. Compared to other building materials, steel retains its structural integrity for an extended period in the event of a fire, thereby reducing the risk of collapse during rescue operations. To conclude, it is evident that steel angles can indeed be utilized in earthquake-resistant building designs. Their exceptional strength, ductility, and capability to withstand lateral loads make them an invaluable component in structural systems. By implementing appropriate design and installation techniques, steel angles can enhance the overall resilience and safety of buildings situated in earthquake-prone areas.

- Q:Can steel angles be used for manufacturing equipment frames?

- Yes, steel angles can be used for manufacturing equipment frames. Steel angles are commonly used in construction and industrial applications due to their strength, durability, and versatility. They provide structural support and stability, making them suitable for creating frames for various types of equipment.

- Q:How do you calculate the axial compression capacity of a steel angle?

- To calculate the axial compression capacity of a steel angle, you would need to consider several factors such as the dimensions and properties of the angle, the material properties, and the boundary conditions. The calculation typically involves determining the slenderness ratio, which is the ratio of the length of the angle to its thickness. This ratio helps determine whether the angle will fail in compression or buckling. The axial compression capacity can then be calculated using relevant design codes or formulas, taking into account factors such as the yield strength of the material and any additional considerations specific to the application.

- Q:How do you calculate the bending stress in a steel angle?

- In order to determine the bending stress in a steel angle, one must have a grasp of the fundamentals of bending moment and the moment of inertia of the angle. Firstly, the bending moment acting on the steel angle needs to be determined. This can be achieved by considering the applied load or force and its distance from the point of rotation. The bending moment is obtained by multiplying the applied load by the distance between the point of rotation and the line of action of the force. Next, the moment of inertia of the steel angle needs to be established. The moment of inertia measures an object's resistance to changes in its rotational motion and is dependent on its shape and size. For a steel angle, the moment of inertia can be calculated using the appropriate formula for its specific cross-sectional shape. Once the bending moment and moment of inertia have been determined, the bending stress can be calculated using the following formula: Bending Stress = (Bending Moment * Distance from Neutral Axis) / Moment of Inertia The bending stress denotes the internal resistance within the steel angle to the bending moment and is typically expressed in units of force per unit area, such as pounds per square inch (psi) or newtons per square meter (Pa). It is important to note that the calculation of bending stress assumes the steel angle behaves elastically, meaning it does not experience excessive deformation or permanent damage. If the applied bending moment exceeds the elastic limit of the steel angle, plastic deformation or failure may occur, necessitating the use of a different analysis method.

- Q:Can steel angles be used for manufacturing decorative brackets?

- Yes, steel angles can be used for manufacturing decorative brackets. Steel angles are versatile and can be easily fabricated into various shapes and sizes, making them suitable for creating decorative brackets. The angles can be cut, welded, and formed into different designs to achieve the desired aesthetic appeal. Furthermore, steel angles offer strength and durability, ensuring that the decorative brackets can support the weight of the objects they hold. Whether it is for architectural purposes or home décor, steel angles provide a reliable and cost-effective option for manufacturing decorative brackets.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Hot Rolled Steel Unequal Angle Steel Good Price SS400 Competitive Price

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 35000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords