Hot Rolled Steel Strip Coils with high quality

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 66 m.t.

- Supply Capability:

- 222555 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

Applications of Steel Strip Coils:

1:Chemical industry equipment, Industrial tanks

2:Medical Instruments,Tableware, Kitchen utensil,kitchen ware

3:Architectural purpose, Milk & Food processing facilities

Festures of Steel Strip Coils:

1. Each coil is closely covered by oil paper or plastic film.

2. Outside it is firmly packed with sack cloth or compound paper.

3. Steel strap or PP strap to pack the outside to ensure safety.

Specifications of Steel Strip Coils:

Household Appliance | Refrigerator shutter &side panels, Rice Cooker, Washer, Microwave Ovens, Freezers, Air conditions, Water Heaters, Sterilization Cabinets, Range Hoods, Computer Panels , DVD/DVB panels, TV back panel etc. |

Construction Material | Fireproof Door &Kitchen Cabinet ,Ceiling, Sanitary Unit, Elevator etc. |

Transportation | Car, Ship, Trains, Aircraft Equipment. etc. |

Education and Health Field | Electronic Writing Boards, Projection Screens, Clean Operating Rooms, etc. |

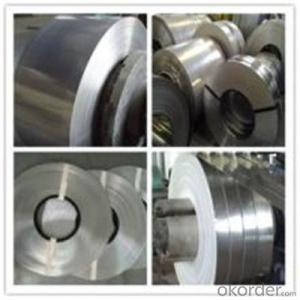

Images of Steel Strip Coils:

FAQ

1.What's your MOQ?

25MT, it is for one container.

2.Do you have QC teams?

Yeah, sure, our QC team is very important, they will keep the quality control for our products.

3. What's your normal delivery time?

Our delivery time about 10-20days for standard sizes, if you have other requirements like hardness and width ,it is about 20-40days.

- Q:What are the different methods for bending steel strips?

- There are several methods for bending steel strips, each with its own advantages and applications. Some of the most common methods include: 1. Press brake bending: This method involves using a press brake machine, which applies force to bend the steel strip into the desired shape. The strip is placed between a punch and a die, and the machine applies pressure to create the bend. Press brake bending is commonly used for precision bending and creating complex shapes. 2. Roll bending: In this method, the steel strip is passed through a series of rollers that gradually apply pressure to bend the strip. This technique is typically used for large-scale, continuous bending operations and is suitable for creating long, curved shapes. 3. Induction bending: This method involves using an induction heating system to heat the steel strip to a malleable temperature. Once heated, the strip is bent using a bending machine or a specially designed mandrel. Induction bending allows for precise control over the bending process and is commonly used for creating smooth and consistent bends in large steel strips. 4. Rotary-draw bending: This method utilizes a bending machine equipped with a rotating die, which grips the steel strip and pulls it around a bend form. Rotary-draw bending is often used for producing tight, precise bends in small to medium-sized steel strips. 5. Mandrel bending: Mandrel bending involves inserting a mandrel, typically a solid rod or flexible coil, into the steel strip before bending. The mandrel provides support to the inner surface of the strip, preventing it from collapsing or deforming during the bending process. This method allows for the creation of smooth, wrinkle-free bends and is commonly used in applications where a high-quality finish is required. 6. Hammer bending: This traditional method involves using a hammer or mallet to manually shape the steel strip by striking it against a form or mold. Although it is a labor-intensive process, hammer bending is often used for small-scale or custom bending applications. Each method has its own advantages and limitations, and the choice of bending method will depend on factors such as the desired shape, material properties, production volume, and budget.

- Q:How are steel strips used in the manufacturing of bearings?

- Steel strips are used in the manufacturing of bearings as they act as the raw material for producing the inner and outer rings of the bearing. These strips are shaped, machined, and heat-treated to form the necessary ring components, which provide support, alignment, and enable the smooth rotation of the bearing.

- Q:How do steel strips differ in terms of hardness?

- Steel strips can differ in terms of hardness based on the specific type of steel used, the manufacturing process, and any additional heat treatment or tempering methods employed. Different grades of steel, such as mild steel, high carbon steel, or stainless steel, have varying levels of hardness. Hardness can also be influenced by factors like the amount of carbon or other alloying elements present in the steel composition. Additionally, the thickness and width of the steel strip can impact its hardness as well.

- Q:What are the common surface defect inspection methods for steel strips?

- There are several common surface defect inspection methods that are widely used for steel strips. 1. Visual Inspection: This is the simplest and most basic method of surface defect inspection. It involves a trained inspector visually examining the steel strips for any visible defects such as scratches, dents, cracks, or discoloration. While this method is subjective and relies on the inspector's skills and experience, it can still be effective for identifying major defects. 2. Magnetic Particle Inspection (MPI): MPI is a non-destructive testing method that uses magnetic particles to detect surface defects in steel strips. The steel strip is magnetized, and magnetic particles are applied to the surface. Any defects, such as cracks or discontinuities, will cause the magnetic particles to gather at these locations, making them visible to the inspector. 3. Ultrasonic Testing (UT): UT is another non-destructive testing method commonly used for inspecting steel strips. It involves the use of high-frequency sound waves that are transmitted into the steel strip. Any defects or discontinuities in the material will cause the sound waves to bounce back, creating echoes that can be detected and analyzed to identify surface defects. 4. Eddy Current Testing (ECT): ECT is a non-destructive testing method that uses electromagnetic induction to detect surface defects in conductive materials like steel. A coil carrying an alternating current is placed near the surface of the steel strip, creating eddy currents in the material. Any defects or changes in the material's conductivity will cause a variation in the eddy currents, which can be detected and analyzed to identify surface defects. 5. X-ray Inspection: X-ray inspection is a method that uses X-rays to detect surface and internal defects in steel strips. X-rays can penetrate the material and create an image of its internal structure. This method is particularly useful for detecting internal defects such as voids, inclusions, or delaminations that may not be visible by visual inspection. These are some of the common surface defect inspection methods used for steel strips. The choice of method depends on factors such as the type and size of defects, the required sensitivity, and the cost-effectiveness of the inspection.

- Q:What are the cost considerations when using steel strips?

- Some of the cost considerations when using steel strips include the price of the raw material, transportation and handling costs, processing and manufacturing expenses, as well as any additional treatments or coatings required. The size and thickness of the strips can also impact the overall cost, as well as any customization or special requirements. Additionally, market demand and fluctuations in steel prices can affect the cost of steel strips.

- Q:How are steel strips tempered for increased hardness?

- Steel strips are tempered for increased hardness through a process called heat treatment. After the initial steel strip is heated to a specific temperature, it is rapidly cooled, known as quenching, to increase its hardness. Following this, the strip is reheated to a lower temperature and then slowly cooled, a process called tempering, to reduce any brittleness and further enhance its hardness.

- Q:1 can thick galvanized steel square pipe burn welding?

- Welding can only use 2.5 of the electrode, the current transferred to 80A, slowly welding, yes, I have also welded. If the line is conditional, do better with sub fluorine welding or oxygen welding.

- Q:How are steel strips inspected for internal defects?

- Steel strips are inspected for internal defects using various non-destructive testing methods. One common method is ultrasonic testing, where high-frequency sound waves are passed through the steel strip. If there are any internal defects such as cracks, voids, or inclusions, the sound waves will be reflected differently, and these reflections are detected by sensors. By analyzing the pattern of the reflections, the size, shape, and location of the internal defects can be determined. Another method used is magnetic particle inspection. In this technique, the steel strip is magnetized, and iron particles are applied on the surface. If there are any internal defects, the magnetic field within the strip will be disrupted, causing the iron particles to cluster around the defects. This clustering can be visually detected and indicates the presence of internal defects. Liquid penetrant testing is also employed to inspect steel strips for internal defects. In this process, a liquid dye penetrant is applied to the surface of the strip. The dye penetrates into any surface openings, such as cracks or voids, and is left to dwell for a specific period. After that, the excess dye is removed, and a developer is applied. The developer draws the remaining dye out of the defects, making them visible and easily detectable under proper lighting conditions. Additionally, eddy current testing can be used to inspect steel strips for internal defects. This method involves passing an alternating current through a coil, creating an electromagnetic field. As the coil is moved along the surface of the strip, any variations in the electromagnetic field caused by internal defects are detected by sensors. These variations are then analyzed to identify the presence and characteristics of internal defects. Overall, these non-destructive testing methods provide reliable and efficient ways to inspect steel strips for internal defects without causing any harm to the material. They play a crucial role in ensuring the quality and integrity of steel strips before they are used in various applications.

- Q:What is the maximum weight capacity of steel strips?

- The maximum weight capacity of steel strips can vary depending on various factors such as the thickness, width, and length of the strips. Generally, steel strips can have weight capacities ranging from a few hundred pounds to several thousand pounds. It is important to consult specific product specifications or industry standards to determine the exact maximum weight capacity of steel strips for a particular application.

- Q:How are steel strips used in the defense industry?

- Steel strips are commonly used in the defense industry for various applications such as manufacturing armored vehicles, building naval ships, and constructing military aircraft. These strips are used to reinforce structures, provide protection, and enhance durability in critical defense equipment.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Hot Rolled Steel Strip Coils with high quality

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 66 m.t.

- Supply Capability:

- 222555 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords