Hot Rolled Steel Sheets Boats for Sale in China

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Description of steel sheets:

Q235 1.8M width hot rolled carbon steel sheet

Size:30-2440mm

Thickness:0.2-100mm

Length can cut as per customer requirement

Festures of steel sheets:

1. Packing: a. Small size: in bundles

2. Big size: in bulk

3. in plastic packing or as per customer request

4. Delivery time: a. Normal size: within 7days send from warehouse directly

5. Special size: with 25-30days customer made for you

6.Trade terms:FOB/CFR/CIF/DDU

7. Shippment: a. length:≤5.8m loaded in 20FT Container with 25-27tons

8.length:≤11.8m loaded in 40FT Container with 25-27tons

9. lengnth:≥12m shipped by bulk vessel, FILO terms

Specifications of steel sheets:

| Product | TOP KING alibaba China manufacturer HOT ROLLED STEEL SHEETS boats for sale |

| Place of origin | Tianjin,China mainland |

| MOQ | 10 ton |

| Thickness | 1mm-200mm |

| Width | 1000mm-3000mm |

| Length | 1000mm-12000mm |

| Application | widely |

| Standard | AISI,ASTM,BS,DIN,JIS,GB,etc |

| Grade | A572,A573,A633,A678,A709,A710,G3101,G3136,etc |

| Tpye | Steel plate |

| Surfacing | Coated |

| Productive Technology | Hot Rolled & Cold Rolled |

| Price | FOB USD 500-900 per ton |

| Port | TIANJIN |

| Payment Terms | L/C,T/T,Western Union |

| Product Ability | 10000 tons per month |

| Delivery | 10 days after deposit or according to customers' quantity |

| Packing | standard seaworthy export packing or as the request of customers |

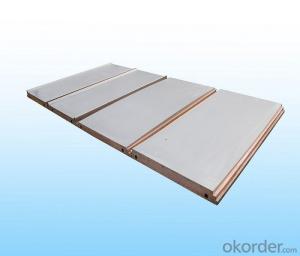

Images of steel sheets:

FAQ:

1. What is your package?

Packing situation: standard seaworthy packing or as customer required.

2. How long is the lead time?

Delivery time: 45 days after order confirmed.

3. What payment term do you accept?

Payment: T/T or L/C at sight.

- Q:when you have a piece of flat metal (really thin), and you draw on it with something pointy, and it turns out really pretty on both sides?and do you know where i can buy some of that metal?

- No. Because it Is only made of rock and dust.

- Q:i have a machete i bought at a swapmeet a while back. i have a bastard mill file to sharpen it. its cut in only one direction on each side. my machete does get a bit sharp but never surgical. is it bad technique? what else can i use? i dont know of anyplace around me to get professional sharpening tools.

- I took an inventory of my cars to see which I liked and here is the vote talley: FWD: 0 RWD: 6 It is like this, I have owned FWD cars. But I do not like the way the tires wear out so fast on the front end. A FWD car uses the front tires for steering, traction and they do most of the braking. This results in the adhesive force being split too many ways all at once. When the limits of adhesion are reached- it does not happen a little and there is little warning. At least with RWD I can still use throttle steer when I get into trouble on a turn. Try the same thing in a FWD car and you will end up in a ditch. Don't give me that snow excuse! Too many drivers expect the car they drive to make up for a lack of driving skills. If the roads are bad enough to keep a RWD car off of the road the driver needs AWD or 4WD. Considering the power loss in a AWD because of the extra moving parts, a 4WD is a better choice. Yes, FWD is nice and the best tool for most drivers. But I am not a driver that fits into the class with most drivers! I grew up with RWD and drove them in blizzards. With the right tires (and chains if needed) I can get a car over roads that most drivers would not even take a 4WD. Don't get me wrong- there are times I don't go any where and when I say I am staying off the roads other drivers should too.

- Q:Hey guys, I'm totally stumped with this question:Given that you possess the following materials:(i) two sheets of copper of uniform thickness;(ii) one sheet of mica of uniform thickness 0.10 mm and dielectric constant κ 6;(iii) one sheet of glass of uniform thickness 2.0 mm and dielectric constant κ 7;(iv) one sheet of paraffin wax of uniform thickness 1.0 cm and dielectric constantκ 2;determine which sheet, or combination of sheets, will produce a parallel plate capacitor ofthe largest capacitance when placed between the copper sheets. Assume that all sheetshave the same shape.I just can't seem to find an equation to find equivelant capacitances of multiple dielectrics in a capacitorThanks!!

- They are completely different fluids/liquids. Not related whatsoever. Transmission fluid is a pinkish red and is quite oily.

- Q:I am so confused on this.For example, i have to write the formula for Cupric Sulfide.This is ionic, isn‘t it? And if this is ionic then don‘t you cross and drop the charges?But on my answer sheet it says it is CuS Can someone please walk me through how to do this?

- You may be burning oil from the top of your engine then the oily smoke blows right across the windshield. Or you live by a expressway and the diesel smoke from trucks coats the windshield. I would clean the windshield and apply Rain-X this would help detour the oil from sticking. See if the car has this residue over the entire car, if so cover it when not in use.

- Q:I have never done it before but would like to try my hands on that just as a hobby. where can i find the materials for that? I stay in sacramento, California. Is it necessary to take any classes to start off or csn i just try it by myself home? Plz guide me

- My 71 Camaros license plate flips down. Funny thing is my 84 Z28 license plate flips down but only has hatch lock behind it.

- Q:A square hole 9.8 cm along each side is cut in a sheet of copper.Find the change in the area of this hole if the temperature of the sheet is increased by 68 K. The coefficient of expasion is 1.7 × 10?5 (?C)?1.Answer in units of cm2

- square hole side 9.8 cm Area 9.8^2 96.04 cm^2 Increase in temperature 68° K coefficient of expansion, 1.7 x 10^-5 m / °C 0.017 cm/°C, increase in side 9.8 + 0.017 x 68 10.956 cm, In crease Area 10.956^2 120.034 cm^2 Change in area 120.034 - 96.04 24 cm^2 ANSWER

- Q:What do you mean by "2A/H CCL" in the PCB board?

- Copper-clad laminatesIt is a kind of deposited copper plate made of polytetrafluoroethylene plate and coated with copper foil. It is mainly used as printed circuit board in high frequency and ultra high frequency circuit

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Hot Rolled Steel Sheets Boats for Sale in China

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches