Hot Rolled Steel Plates HRC for Sale in China

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 59 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Description of steel sheets:

A36/A516 Gr.60/70 hot rolled oil tank/carbon boiler steel plate/sheet

1.Width:1500--4020mm

2.Length:3000-27000mm

Festures of steel sheets:

steel plate are widely used in shipping building,engineer construction,

mechanical manufacturing,the size of alloy steel sheet can be made

according to clients required.

Specifications of steel sheets:

1) Cold rolling

The advantages of cold rolling are good dimensional accuracy ,surface quality ,low surface roughness ,high mechanical properties.The steel surface of the coldrolled (forging) state delivery has oxide skin coverage and there is a great internal stress, so likely to suffer corrosion or rust,.Therefore ,its packaging and storage have relatively strict standards

2) Hot rolling

Hot rolling (forging) steel plate’s termination of a temperature is 800900 degrees Celsius, then generally natural air cooling.Hotrolled steel state because of the surface is covered with a layer of oxide scale,so having some corrosion resistance, less stringent storage and transport requirements, unlike steel cold-rolled state delivery.

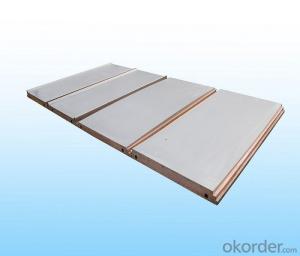

Images of steel sheets:

FAQ:

1. What is your package?

Packing situation: standard seaworthy packing or as customer required.

2. How long is the lead time?

Delivery time: 45 days after order confirmed.

3. What payment term do you accept?

Payment: T/T or L/C at sight.

- Q:can you sujest low resistance around 10^-9?

- Very tough. A sheet of copper 3 cm square and 1 mm thick will have a resistance close to 10^–9 Ω between its two flat faces ( that is , with the connectors separated by 1 mm of copper. ) . But that is the problem the connectors will have much more resistance and totally swamp the tiny resistance of the Cu sheet. What on earth do you what it for ?

- Q:Ask the copper plate for annealing and help!

- Copper, then between 250~400 degrees, 2 hours bar, look at the purity, rolling shape variables, and the size of the grain before rolling, brass does not understand, hey hey!

- Q:When a 10.0 g sheet of copper is initially at 22.0 degrees Celsius is placed on a 20.0 g sheet of aluminum initially at 75.0 degrees Celsius, what is the final temperature of the the two metals (assuming no heat is lost to the surroundings?) Ccu 0.385 J/gC Cal 0.900 J/gCThanks I will award best explanation to find it. I know the answer is 65.7 degrees Celsius just don‘t know how

- The amount of heat energy before the amount of heat energy afterwards (since none is lost, and none is converted to other forms). Next the final temperature is the same for both metals. Remember to use kelvin or Rankine units for all thermodynamic calcuclations. m1 * cp1 * T1 + m2 * cp2 * T2 (m1 * cp1 + m2 * cp2) * T3 Just insert your numbers and you have T3.

- Q:want to build self propelled recreational water craft from imagination?

- I think you need something more than imagination. An engine, some wood at least

- Q:2.00 X 10^5 lbs of copper sheets eqauls how many atoms of copper?

- Sounds like something broke in the wiper drive train. The stress of the motor trying to move the wipers was more then it could handle.

- Q:i want to build a ice machine i have a power cable plug metal sheets and copper ect available what voltage does a mini ice maker say 8 ice cubes square need to run and what motherboard card is needed and any other parts

- Just freeze ice cubes in the family refrigerator. Cut the plug off the power cable, and destroy it so no- one else can put it in an outlet and get fried. Sell the metal for scrap. That way you make money from your mistake!

- Q:What kind of paper should be chosen in the printer?

- Mine is high quality glossy paper, you can set it up for advanced paper. As long as the paper is not bad, the copy request is not very fine, and the effect is the same.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Hot Rolled Steel Plates HRC for Sale in China

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 59 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords