Hot Rolled Steel I-Beam in European Standard

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t

- Supply Capability:

- 10000 m.t/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

OKorder is offering high quality Hot Rolled Steel I-Beams at great prices with worldwide shipping. Our supplier is a world-class manufacturer of steel, with our products utilized the world over. OKorder annually supplies products to European, North American and Asian markets. We provide quotations within 24 hours of receiving an inquiry and guarantee competitive prices.

Product Applications:

Hot Rolled Steel I-Beams are ideal for structural applications and are widely used in the construction of buildings and bridges, and the manufacturing, petrochemical, and transportation industries.

Product Advantages:

OKorder's Steel I-Beams are durable, strong, and resist corrosion.

Main Product Features:

· Premium quality

· Prompt delivery & seaworthy packing (30 days after receiving deposit)

· Corrosion resistance

· Can be recycled and reused

· Mill test certification

· Professional Service

· Competitive pricing

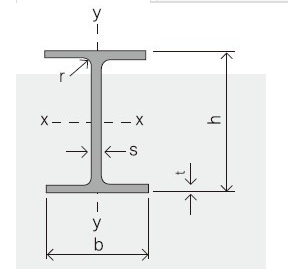

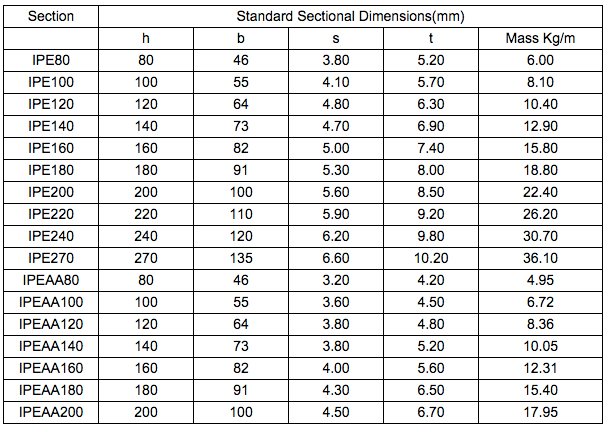

Product Specifications:

Manufacture: Hot rolled

Grade: Q195 – 235

Certificates: ISO, SGS, BV, CIQ

Length: 6m – 12m, as per customer request

Packaging: Export packing, nude packing, bundled

FAQ:

Q1: Why buy Materials & Equipment from OKorder.com?

A1: All products offered byOKorder.com are carefully selected from China's most reliable manufacturing enterprises. Through its ISO certifications, OKorder.com adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Q2: The products are invoicing on theoritical weight or on actual weight?

A2: We can do it in both manners, according to the customers' request.

Q3:What's your payment terms ?

A3:Mostly,we collect the money by T/T and LC at sight . We also accept time LC at 90/120 days sigh

.

Images:

- Q:Can steel I-beams be used in theaters or auditoriums?

- Yes, steel I-beams can certainly be used in theaters or auditoriums. In fact, they are commonly used in the construction of these types of buildings due to their strength, durability, and versatility. Steel I-beams provide exceptional structural support and can handle heavy loads, making them ideal for large open spaces where a significant amount of weight needs to be supported. Additionally, steel I-beams can be easily fabricated to meet specific design requirements and can be used to create a variety of architectural elements, such as balconies, mezzanines, and catwalks. Their use in theaters and auditoriums ensures the safety and stability of the structure, allowing for a seamless integration of lighting, sound equipment, and other technical components necessary for performances.

- Q:Can steel I-beams be used for underground structures or tunnels?

- Underground structures or tunnels can indeed utilize steel I-beams. Given its robustness, longevity, and rust resistance, steel remains a favored option for subterranean construction. Structural reinforcement is effectively provided by steel I-beams, which are frequently employed in the assembly of subterranean structures like tunnels, subway systems, underground parking lots, and storage facilities. These beams exhibit exceptional load-bearing capabilities and offer stability within underground settings. Furthermore, steel I-beams can be readily fabricated and tailored to suit precise design specifications, thus rendering them an adaptable alternative for subterranean construction endeavors.

- Q:Can steel I-beams be used in foundation or basement construction?

- Yes, steel I-beams can be used in foundation or basement construction. Steel I-beams are commonly used in construction due to their strength and durability. They can provide excellent support for the foundation or basement walls, especially in areas with unstable soil conditions or when large loads need to be supported. Additionally, steel I-beams are resistant to rot, pests, and moisture, which makes them an ideal choice for basement construction. However, it is important to consult with a structural engineer or a construction professional to ensure the appropriate size and placement of the steel I-beams for the specific building requirements and conditions.

- Q:What are the standard sizes and dimensions of steel I-beams?

- The standard sizes and dimensions of steel I-beams vary depending on the specific requirements and industry standards. However, some common standard sizes include 3", 4", 6", 8", 10", 12", 14", 16", 18", 20", 22", 24", and larger. These dimensions refer to the height of the beam, while the width can range from 1.375" to 12.25" or more. The weight per foot and length of the beam also vary based on the size and type of I-beam.

- Q:Can steel I-beams be used in healthcare or hospital construction?

- Yes, steel I-beams can be and are commonly used in healthcare or hospital construction. They provide structural support and are often used in the framework of the building to withstand heavy loads and ensure the safety and stability of the structure.

- Q:How do steel I-beams contribute to the overall energy efficiency of a structure?

- Steel I-beams contribute to the overall energy efficiency of a structure in several ways. Firstly, steel is a highly durable and long-lasting material, which means that structures built with steel I-beams require less maintenance and repairs over time. This leads to reduced energy consumption and costs associated with upkeep and renovation. Additionally, steel I-beams have excellent load-bearing capabilities, allowing for larger spans and open floor plans. This means that fewer beams are needed to support the structure, resulting in reduced material usage and, consequently, lower energy requirements during manufacturing and transportation. Moreover, steel is a highly recyclable material, and steel I-beams can be easily repurposed or recycled at the end of their lifespan. Recycling steel requires significantly less energy compared to the production of new steel, resulting in reduced energy consumption and greenhouse gas emissions. Furthermore, steel I-beams are often used in conjunction with other energy-efficient building components, such as insulated panels or double-glazed windows. This integration improves the overall thermal performance of the structure by reducing heat transfer, minimizing energy losses, and enhancing insulation. Lastly, steel I-beams can be designed to accommodate various energy-efficient systems, such as solar panels or geothermal heat pumps. These systems can be integrated into the structure, further reducing energy consumption by providing renewable energy sources or utilizing the earth's natural heat. Overall, steel I-beams contribute to the energy efficiency of a structure through their durability, load-bearing capabilities, recyclability, compatibility with energy-efficient components, and ability to accommodate sustainable technologies. By incorporating steel I-beams into the design and construction of a building, energy consumption, costs, and environmental impact can be significantly reduced.

- Q:How does the arch concrete of the tunnel be poured up? How can the support be used before the casting? Is it made of I-beam? Is it directly supported by earthwork?

- The excavation of the tunnel face, slag, to the primary support system, first hit the bolt, then use steel or steel made of steel, installation support in tunnel contour, and then sprayed concrete (poor surrounding rock hanging steel mesh, then sprayed fiber concrete).

- Q:Can steel I-beams be used for curtain wall systems?

- Indeed, curtain wall systems can make use of steel I-beams. In commercial buildings, these systems are usually employed to offer an external façade and bear the weight of the structure. Steel I-beams are a popular choice for curtain wall systems due to their exceptional load-bearing capacities and ability to withstand the forces exerted on the building. They provide structural support and can be tailored to accommodate the weight of curtain wall panels, glass, and other elements. Furthermore, steel I-beams possess durability and resilience against various weather conditions, rendering them appropriate for application in curtain wall systems.

- Q:Can steel I-beams be used in water or wastewater treatment plant construction?

- Water or wastewater treatment plant construction can make use of steel I-beams. These I-beams are often chosen for construction purposes due to their strength, durability, and versatility. They are capable of bearing heavy loads and maintaining structural integrity, making them suitable for a range of applications within water and wastewater treatment plants. Within water treatment plants, steel I-beams find application in supporting and reinforcing structures that house treatment processes. They are employed in the construction of sedimentation tanks, clarifiers, filtration systems, and chemical treatment facilities. By providing a robust framework, steel I-beams can withstand the weight of equipment, machinery, and water storage tanks utilized in the treatment process. Likewise, in wastewater treatment plants, steel I-beams are versatile and can be used for various purposes. They can be employed in the construction of aeration tanks, digesters, sludge dewatering facilities, and pumping stations. Steel I-beams are capable of supporting the weight of large tanks and equipment, ensuring the stability and safety of the structures. Moreover, steel I-beams possess resistance to corrosion, rendering them particularly suitable for water and wastewater treatment plant environments. The presence of chemicals, moisture, and fluctuating temperatures in these facilities can cause deterioration in certain construction materials. However, steel I-beams maintain their durability and can withstand these harsh conditions, making them a reliable choice for long-term use in water and wastewater treatment plant construction. In conclusion, steel I-beams are commonly employed in water and wastewater treatment plant construction due to their strength, durability, versatility, and resistance to corrosion. They offer the necessary support and structural integrity required for the efficient and safe operation of treatment processes.

- Q:What's the difference between I-beam ipeaaa and IPE?

- I-beam is divided into ordinary I-beam and light I-beam, H steel three. It is a section steel whose shape is trough.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Hot Rolled Steel I-Beam in European Standard

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t

- Supply Capability:

- 10000 m.t/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords