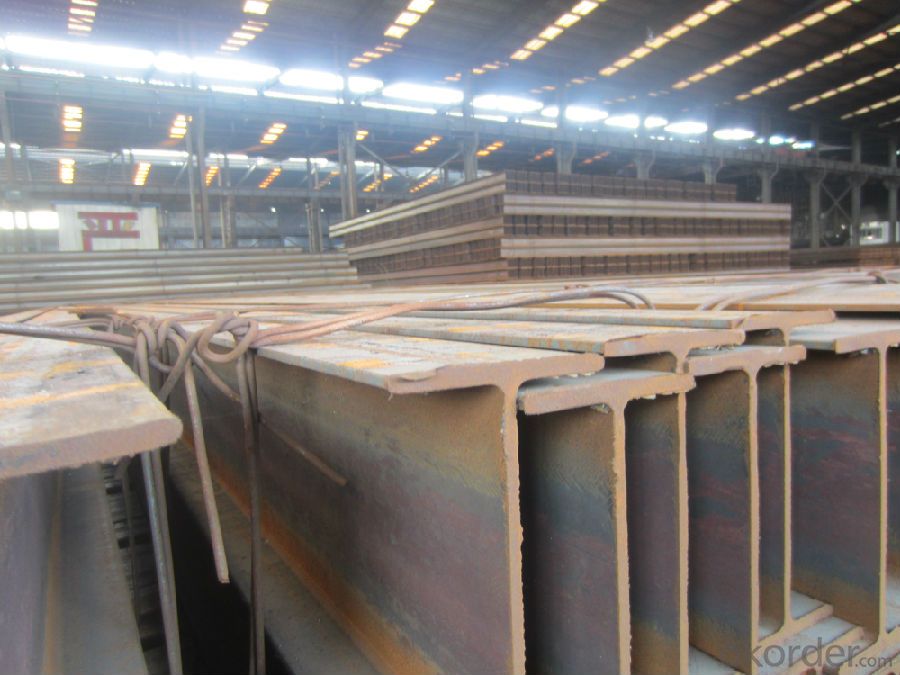

Hot Rolled Steel H-BEAM JIS SS400 GB Q235 OR Equivalent

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

Product Description:

OKorder is offering Hot Rolled Steel H-BEAM JIS SS400 GB Q235 OR Equivalent at great prices with worldwide shipping. Our supplier is a world-class manufacturer of steel, with our products utilized the world over. OKorder annually supplies products to European, North American and Asian markets. We provide quotations within 24 hours of receiving an inquiry and guarantee competitive prices.

Product Applications:

Hot Rolled Steel H-BEAM JIS SS400 GB Q235 OR Equivalent are ideal for structural applications and are widely used in the construction of buildings and bridges, and the manufacturing, petrochemical, and transportation industries.

Product Advantages:

OKorder's Hot Rolled Steel H-BEAM JIS SS400 GB Q235 OR Equivalent are durable, strong, and resist corrosion.

Main Product Features:

· Premium quality

· Prompt delivery & seaworthy packing (30 days after receiving deposit)

· Corrosion resistance

· Can be recycled and reused

· Mill test certification

· Professional Service

· Competitive pricing

Product Specifications:

1. Standard: JIS 3192

2. Grade: SS400 or Equivalent

3. Length: 10m, 12m as following table

4. Invoicing on theoretical weight or actual weight as customer request

5.Payment: TT or L/C

Size and Mass of H beam:

Size (mm) | Mass (Kg/m) | Size (mm) | Mass (Kg) |

298*149*5.5 | 32.0 | 294*200*8.0 | 55.8 |

300*150*6.5 | 36.7 | 294*302*12.0 | 83.4 |

Usage of Prime Hot Rolled H Beam Steel :

(1). for the plant, high-rise building construction

(2). for the bridge, shipment building

(3).for lifting and transportation machinery, equipment manufacturing base building

(4). for the support, foundation pile manufacturing

Packaging & Delivery of Hot Rolled Structural Steel H Beam

1. Packing: it is nude packed in bundles by steel wire rod

2. Bundle weight: not more than 3.5MT for bulk vessel; less than 3 MT for container load

3. Marks:

Color marking: There will be color marking on both end of the bundle for the cargo delivered by bulk vessel. That makes it easily to distinguish at the destination port.

Tag mark: there will be tag mark tied up on the bundles. The information usually including supplier logo and name, product name, made in China, shipping marks and other information request by the customer.

If loading by container the marking is not needed, but we will prepare it as customer request.

4. Transportation: the goods are delivered by truck from mill to loading port, the maximum quantity can be loaded is around 40MTs by each truck. If the order quantity cannot reach the full truck loaded, the transportation cost per ton will be little higher than full load.

5. Delivered by container or bulk vessel

FAQ:

Q1: Why buy Materials & Equipment from OKorder.com?

A1: All products offered byOKorder.com are carefully selected from China's most reliable manufacturing enterprises. Through its ISO certifications, OKorder.com adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

Q3: How soon can we receive the product after purchase?

A3: Within three days of placing an order, we will begin production. The specific shipping date is dependent upon international and government factors, but is typically 7 to 10 workdays.

Q4: What makes stainless steel stainless?

A4: Stainless steel must contain at least 10.5 % chromium. It is this element that reacts with the oxygen in the air to form a complex chrome-oxide surface layer that is invisible but strong enough to prevent further oxygen from "staining" (rusting) the surface. Higher levels of chromium and the addition of other alloying elements such as nickel and molybdenum enhance this surface layer and improve the corrosion resistance of the stainless material.

Q5: Can stainless steel rust?

A5: Stainless does not "rust" as you think of regular steel rusting with a red oxide on the surface that flakes off. If you see red rust it is probably due to some iron particles that have contaminated the surface of the stainless steel and it is these iron particles that are rusting. Look at the source of the rusting and see if you can remove it from the surface.

Images:

- Q:Can steel H-beams be used for residential garages?

- Yes, steel H-beams can be used for residential garages. They are commonly used in construction for their strength and durability, making them suitable for supporting the weight of a garage structure.

- Q:What are the fire protection requirements for steel H-beams?

- The fire protection requirements for steel H-beams depend on the building codes and regulations in place. In general, steel H-beams may require fireproofing or fire-resistant coatings to meet the required fire resistance ratings. The specific fire protection requirements can vary based on factors such as the size and location of the H-beams within the building, the occupancy type, and the fire protection strategy adopted. It is important to consult local building codes and fire protection experts to determine the appropriate fire protection measures for steel H-beams in a specific construction project.

- Q:Can steel H-beams be used for railway bridges or overpasses?

- Certainly! Steel H-beams are a viable option for railway bridges or overpasses. They are widely used in construction owing to their remarkable strength-to-weight ratio, rendering them suitable for bearing heavy loads. The materials required for railway bridges and overpasses must be robust and enduring to support the weight of trains, and steel H-beams are well-suited for this purpose. They provide structural stability, possess the ability to endure significant loads and forces, and can span considerable distances. Moreover, steel H-beams possess resistance against corrosion, a crucial attribute for structures exposed to the elements. All in all, due to their strength, durability, and versatility, steel H-beams are a favored choice for railway bridges and overpasses.

- Q:How do steel H-beams compare to concrete beams in terms of construction speed?

- Steel H-beams are generally faster to construct compared to concrete beams. This is primarily due to the nature of steel as a material, which allows for easier and faster fabrication and assembly. Steel H-beams can be prefabricated off-site, allowing for efficient mass production and faster delivery to the construction site. In contrast, concrete beams require more time for construction. The process involves multiple steps, such as formwork installation, pouring and curing of the concrete, and removal of the formwork. These steps take time to complete, and the curing process alone can take several days or even weeks, depending on the size and complexity of the beams. Moreover, steel H-beams are lighter in weight compared to concrete beams, making them easier to handle and install. This results in reduced labor requirements and shorter construction timelines. Additionally, steel beams can be easily adjusted or modified on-site, allowing for faster adjustments during the construction process. Overall, steel H-beams offer significant advantages in terms of construction speed compared to concrete beams. Their prefabrication capabilities, lighter weight, and ease of installation contribute to faster construction timelines, ultimately saving time and costs in the construction process.

- Q:How do steel H-beams perform in terms of noise reduction?

- The primary purpose of steel H-beams in construction projects is to serve as structural elements for buildings, bridges, and infrastructure. However, when it comes to noise reduction, steel H-beams alone do not offer significant insulation. Steel, being a dense material, easily conducts sound vibrations. This means that if a noise source like traffic or machinery directly reaches a steel H-beam, it will effortlessly travel through the steel and be audible on the other side. Consequently, steel H-beams are not effective on their own in reducing noise levels. Nevertheless, noise reduction can be achieved by employing additional measures alongside the use of steel H-beams. For instance, incorporating insulating materials like acoustic panels or soundproofing materials can help absorb or block sound waves, thereby reducing noise transmission through the steel structure. Similarly, by adding resilient mounts or isolators between the steel H-beams and other components, vibrations can be minimized, leading to a decrease in the transmission of noise. To summarize, although steel H-beams themselves lack inherent noise reduction properties, they can be utilized effectively in combination with other noise reduction measures to create a more acoustically insulated environment.

- Q:Are steel H-beams suitable for rooftop structures?

- Steel H-beams are indeed suitable for rooftop structures. Their strength and durability make them an excellent option for bearing heavy loads on rooftops. They can easily support various rooftop structures like solar panels, HVAC systems, and equipment. Moreover, steel H-beams offer exceptional structural support, guaranteeing the stability and safety of the rooftop structure. Furthermore, they possess corrosion resistance and a longer lifespan compared to alternative materials, establishing them as a dependable choice for rooftop applications.

- Q:How do steel H-beams contribute to the overall cost-effectiveness of a project?

- Steel H-beams provide several benefits that contribute to the cost-effectiveness of a project. Firstly, they possess exceptional strength and durability, resulting in minimal maintenance and a long lifespan. This decreases the need for frequent repairs or replacements, leading to cost savings over time. Furthermore, steel H-beams are significantly lighter compared to alternative construction materials like concrete or timber, making transportation and on-site handling easier and cheaper. Consequently, this can reduce labor costs and shorten construction times, ultimately saving money in the overall project budget. In addition, steel H-beams can be prefabricated off-site, enhancing precision and efficiency during the construction process. This reduces the likelihood of errors and wastage, resulting in cost savings in terms of materials and labor. Moreover, steel is an environmentally sustainable material. It can be fully recycled, allowing for repurposing or recycling at the end of its lifespan. This reduces waste and minimizes the project's environmental impact, aligning with the growing demand for sustainable construction practices. It can also lead to potential cost savings through incentives or tax benefits. Overall, incorporating steel H-beams into a construction project offers various cost-effective advantages. Their strength, durability, and low maintenance requirements ensure long-term cost savings, while their lightweight nature and prefabrication capabilities reduce transportation and labor costs. Additionally, the sustainability of steel contributes to potential financial benefits.

- Q:What are the advantages of using steel H-beams in construction?

- There are several advantages to using steel H-beams in construction. Firstly, steel H-beams are incredibly strong and durable. They are made from high-quality steel that can withstand heavy loads and extreme weather conditions. This makes them ideal for supporting structures such as bridges, buildings, and warehouses, where strength and stability are crucial. Secondly, steel H-beams have a high strength-to-weight ratio. This means that they can support large loads while being relatively lightweight themselves. This makes them easier to handle and transport during the construction process, while still providing the necessary strength and support. Another advantage of steel H-beams is their versatility. They can be easily fabricated and customized to fit specific project requirements. They can be cut, welded, and shaped to create various designs and structures, allowing for innovative and unique architectural designs. Additionally, steel H-beams are fire-resistant. Steel is a non-combustible material, which means it does not burn or contribute to the spread of fire. This is especially important in construction projects where fire safety is a priority, such as commercial buildings or high-rise structures. Furthermore, steel H-beams have a long lifespan and require minimal maintenance. Unlike other materials, such as wood, steel does not rot, warp, or decay over time. This reduces the need for frequent repairs or replacements, making steel H-beams a cost-effective choice in the long run. Lastly, steel H-beams are environmentally friendly. Steel is a highly recyclable material, and using steel H-beams in construction reduces the demand for new raw materials. Additionally, steel has a low carbon footprint, making it a sustainable choice for construction projects. In conclusion, the advantages of using steel H-beams in construction include their strength, durability, high strength-to-weight ratio, versatility, fire-resistance, long lifespan, low maintenance requirements, and environmental friendliness. These advantages make steel H-beams an excellent choice for various construction applications.

- Q:Can steel H-beams be used in residential fence or gate structures?

- Yes, steel H-beams can be used in residential fence or gate structures. They are strong, durable, and provide excellent structural support, making them suitable for such applications.

- Q:Are steel H-beams susceptible to rust?

- Yes, steel H-beams are susceptible to rust. Steel is primarily made from iron, and iron is highly prone to corrosion when exposed to moisture and oxygen. Over time, if the H-beams are not properly protected or maintained, they can develop rust. To prevent rust formation, it is essential to apply protective coatings such as paint or galvanization, which act as a barrier between the steel and the surrounding environment. Additionally, regular inspections and maintenance can help identify and address any signs of corrosion before it becomes a significant issue.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Hot Rolled Steel H-BEAM JIS SS400 GB Q235 OR Equivalent

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords