Hot Rolled Steel Equal Angle with High Quality

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

OKorder is offering Hot Rolled Carbon Steel Equal Angle at great prices with worldwide shipping. Our supplier is a world-class manufacturer of steel, with our products utilized the world over. OKorder annually supplies products to European, North American and Asian markets. We provide quotations within 24 hours of receiving an inquiry and guarantee competitive prices.

Product Applications:

According to the needs of different structures, Angle can compose to different force support component, and also can be the connections between components. It is widely used in various building structures and engineering structures such as roof beams, bridges, transmission towers, hoisting machinery and transport machinery, ships, industrial furnaces, reaction tower, container frame and warehouse etc.

Product Advantages:

OKorder's Equal Angle are durable, strong, and resist corrosion.

Main Product Features:

· Premium quality

· Prompt delivery & seaworthy packing (30 days after receiving deposit)

· Corrosion resistance

· Can be recycled and reused

· Mill test certification

· Professional Service

· Competitive pricing

Product Specifications:

1. Invoicing on theoretical weight or actual weight as customer request

2. Length: 6m, 9m, 12m as following table

3. Sizes

Sizes: 25mm-250mm | ||

a*t | ||

25*2.5-4.0 | 70*6.0-9.0 | 130*9.0-15 |

30*2.5-6.6 | 75*6.0-9.0 | 140*10-14 |

36*3.0-5.0 | 80*5.0-10 | 150*10-20 |

38*2.3-6.0 | 90*7.0-10 | 160*10-16 |

40*3.0-5.0 | 100*6.0-12 | 175*12-15 |

45*4.0-6.0 | 110*8.0-10 | 180*12-18 |

50*4.0-6.0 | 120*6.0-15 | 200*14-25 |

60*4.0-8.0 | 125*8.0-14 | 250*25 |

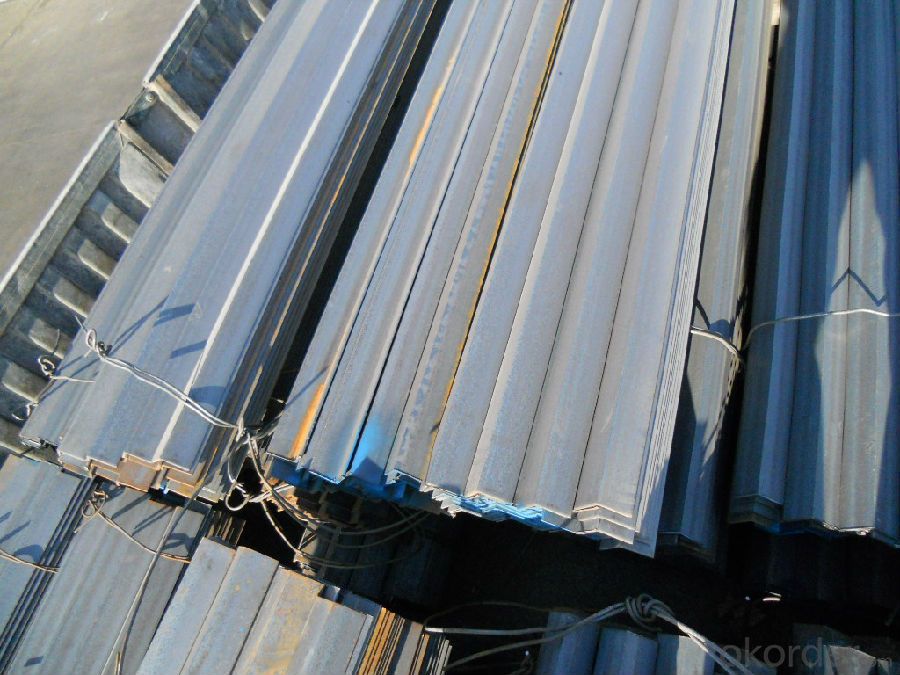

Packaging & Delivery of Angle Steel

1. Packing: it is nude packed in bundles by steel wire rod

2. Bundle weight: not more than 3.5MT for bulk vessel; less than 3 MT for container load

3. Marks:

Color marking: There will be color marking on both end of the bundle for the cargo delivered by bulk vessel. That makes it easily to distinguish at the destination port.

Tag mark: there will be tag mark tied up on the bundles. The information usually including supplier logo and name, product name, made in China, shipping marks and other information request by the customer.

If loading by container the marking is not needed, but we will prepare it as customer request.

FAQ:

Q1: Why buy Materials & Equipment from OKorder.com?

A1: All products offered byOKorder.com are carefully selected from China's most reliable manufacturing enterprises. Through its ISO certifications, OKorder.com adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

Q3: How soon can we receive the product after purchase?

A3: Within three days of placing an order, we will begin production. The specific shipping date is dependent upon international and government factors, but is typically 7 to 10 workdays.

- Q:What is the typical hardness of steel angles?

- The typical hardness of steel angles can vary depending on the specific grade and manufacturing process. However, most commonly used steel angles have a hardness ranging between 120 and 280 on the Brinell hardness scale. It is important to note that the hardness of steel angles can be further influenced by factors such as heat treatment, alloy composition, and surface finishing. Therefore, it is recommended to refer to the specifications provided by the manufacturer or consult relevant industry standards to determine the precise hardness of a particular steel angle.

- Q:Are steel angles suitable for manufacturing equipment enclosures?

- Indeed, steel angles prove to be an appropriate choice for the fabrication of equipment enclosures. Given their robustness and enduring nature, steel angles are widely utilized in both construction and manufacturing sectors. They furnish a solid framework for enclosing equipment and can be effortlessly joined through welding or bolting to ensure a secure enclosure. Moreover, steel angles can be tailored to suit precise dimensions and can be effortlessly adjusted or extended if necessary. In summary, steel angles present a dependable and economically viable solution for the production of equipment enclosures.

- Q:Can steel angles be used in the construction of agricultural buildings?

- Yes, steel angles can definitely be used in the construction of agricultural buildings. Steel angles are a versatile and durable building material that offer several advantages when it comes to constructing agricultural structures. Firstly, steel angles provide excellent structural support and stability. They can be used to create sturdy frameworks for the walls, roofs, and other structural components of agricultural buildings. This is particularly important in agricultural buildings, where heavy machinery and equipment is often stored, and where the structures need to withstand harsh weather conditions and potential impact from animals or other elements. Secondly, steel angles are highly resistant to corrosion and rust, which makes them ideal for agricultural buildings that are exposed to moisture, chemicals, and other potentially corrosive substances. This resistance to corrosion ensures that the structure remains strong and durable over time, reducing the need for frequent maintenance and repairs. Furthermore, steel angles are available in various sizes and shapes, allowing for flexibility in design and construction. They can be easily customized and cut to fit specific building requirements, making them adaptable to various agricultural building designs. Additionally, steel angles can be easily welded or bolted together, making the construction process more efficient and cost-effective. Lastly, steel angles are a sustainable and environmentally friendly choice for agricultural buildings. Steel is a recyclable material, meaning that it can be reused or repurposed once the building has reached the end of its lifespan. This reduces the environmental impact and promotes sustainability in the construction industry. In conclusion, steel angles can be effectively used in the construction of agricultural buildings due to their structural strength, corrosion resistance, design flexibility, and sustainability.

- Q:Can steel angles be used in outdoor or exposed environments?

- Yes, steel angles can be used in outdoor or exposed environments. Steel angles are often made of galvanized steel, which is coated with a protective layer of zinc to prevent rusting. This makes them highly resistant to corrosion and suitable for outdoor applications. Additionally, steel angles are known for their strength and durability, making them a reliable choice for various outdoor structures, such as fences, railings, and supports. However, it is important to note that regular maintenance and inspection may be required to ensure the ongoing integrity and performance of steel angles in outdoor or exposed environments.

- Q:Can steel angles be painted over?

- Yes, steel angles can be painted over. Prior to painting, it is important to clean and prepare the surface by removing any rust, dirt, or grease. Applying a primer will help improve adhesion and longevity of the paint. Once the primer is dry, a suitable paint can be applied to achieve the desired finish and protect the steel angles from corrosion.

- Q:What are the standard tolerances for steel angles?

- The standard tolerances for steel angles can vary depending on the specific grade and size of the angle. However, in general, the standard tolerances for steel angles include dimensional tolerances and straightness tolerances. Dimensional tolerances refer to the allowable variations in the dimensions of the steel angle, such as the thickness, width, and length. These tolerances are typically expressed as a range or a maximum allowable deviation from the specified dimensions. Straightness tolerances, on the other hand, refer to the allowable deviation from a straight line that the steel angle can have. This is typically measured by placing a straight edge along the length of the angle and measuring the maximum gap between the straight edge and the angle. It is important to note that the specific tolerances for steel angles should be determined based on the applicable standards and specifications, such as those provided by industry organizations or regulatory bodies. These standards and specifications will provide the necessary guidance on the acceptable tolerances for steel angles based on their intended use and application.

- Q:What are the different types of corrosion that can affect steel angles?

- There are several different types of corrosion that can affect steel angles, including general corrosion, pitting corrosion, crevice corrosion, galvanic corrosion, and stress corrosion cracking.

- Q:What are the standard sizes of steel angles?

- The standard sizes of steel angles vary, but some common sizes include 1/2 inch, 3/4 inch, 1 inch, 1-1/4 inch, and 1-1/2 inch.

- Q:Are steel angles resistant to earthquakes?

- Steel angles can provide some level of resistance to earthquakes. Steel is known for its high strength and ductility, making it a suitable material for seismic-resistant construction. Steel angles, also known as steel L-shaped beams, are often used in structural applications to provide support and reinforcement. During an earthquake, steel angles can help distribute the seismic forces evenly throughout the structure, thereby reducing concentrated stress points. The L-shape design of steel angles enables them to resist bending and twisting forces, which are common during seismic events. Additionally, steel angles can be interconnected and welded together to form a rigid frame system, enhancing their seismic resistance. This system can absorb and dissipate energy from earthquake-induced vibrations, minimizing damage to the structure. However, it is important to note that the overall seismic resistance of a structure depends on various factors, such as the design, construction methods, and adherence to building codes and regulations. Steel angles alone cannot guarantee complete protection against earthquakes, but when properly integrated into a well-designed seismic-resistant system, they can significantly enhance the structure's ability to withstand seismic forces.

- Q:How do you determine the required size of a steel angle for a specific application?

- There are several factors to consider when determining the necessary size of a steel angle for a particular application. These factors include the load or weight the angle will support, the distance between supports, and the material properties of the steel angle. The first step is to determine the load or weight that the angle will bear. This can be done by calculating the total load applied to the angle, including any objects or structures it will support. It is important to account for static and dynamic loads, as well as potential impact or wind loads. Next, the distance between supports must be taken into account. This is the length over which the angle will span and bear the load. Longer spans typically require larger and stronger angles to maintain structural integrity. Furthermore, the material properties of the steel angle are crucial in determining its necessary size. Steel angles come in different grades and strengths, each with varying load-bearing capacities. It is important to consult engineering and design codes, such as the AISC Manual, to determine the appropriate grade of steel angle that can withstand the calculated load. Once the load, span, and material properties are determined, engineering calculations can be performed to select the necessary size of the steel angle. These calculations typically involve evaluating the angle's moment, shear, and deflection under the applied load. Design tables and equations from the AISC Manual can be used to determine the appropriate size and shape of the angle based on these calculations. To conclude, determining the necessary size of a steel angle for a specific application involves considering the load, span, and material properties of the angle. By performing engineering calculations and referring to design codes, the appropriate size of the angle can be selected to ensure structural safety and integrity.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Hot Rolled Steel Equal Angle with High Quality

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords