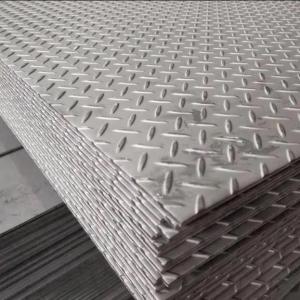

Hot Rolled Steel Chequered Skid Resistance Sheets Chequer Plates

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Hot Rolled Steel Chequered

The steel surface with a pattern called chequered, its pattern into lentil-shaped, diamond, round bean-shaped, oblate shape mixed.

Features

Checkered appearance, can slip, strengthen performance, saving steel and many other advantages.

In transportation, construction, decoration, floor surrounding equipment, machinery, shipbuilding and other fields have a wide range of applications.

Generally, parties to checkered mechanical properties, mechanical performance requirements, so checkered pattern quality mainly as flowering rate, the pattern height, elevation pattern.

Currently on the market common thickness ranging from two kinds of width are common 1250,1500mm from 2.0-8mm.

Specifications

1. Plate width 600 ~ 1800mm, 50mm press upgrade; length of 2000 ~ 12000mm, press the 100mm upgrade.

2. High grain pattern is not less than 0.2 times the thickness of the substrate. Size does not figure as a finished check basis.

3. Plate steel grades according to GB / T700, GB / T712, GB / T4171 requirements.

4. Mechanical properties of steel does not guarantee, when required by the demand side, according to standard regulations, but also by mutual agreement.

5. Hot-rolled steel sheet delivery.

Pictures

- Q:Are the steel sheets heat-resistant?

- Yes, steel sheets are heat-resistant.

- Q:Are the steel sheets suitable for HVAC applications?

- Indeed, HVAC applications find steel sheets to be highly suitable. Steel, being a robust and enduring material, possesses the ability to endure elevated temperatures and mechanical strain, thereby making it an ideal choice for incorporation in heating, ventilation, and air conditioning systems. Commonly, steel sheets are utilized in the construction of various HVAC components like ducts, plenums, and air handling units. They provide exceptional resistance against corrosion, which is of utmost importance in order to preserve the quality and durability of HVAC systems. Moreover, steel sheets can be effortlessly molded and joined through welding, allowing for customization and efficient installation. In summary, the utilization of steel sheets in HVAC applications guarantees dependable performance and longevity of the entire system.

- Q:What is the typical price range for steel sheets?

- The typical price range for steel sheets can vary depending on factors such as size, thickness, grade, and market conditions. However, generally speaking, steel sheets can range in price from around $20 to $200 per sheet.

- Q:How do steel sheets perform in terms of fatigue resistance?

- Steel sheets generally exhibit good fatigue resistance due to their high strength and durability. This means they can withstand repeated loading and unloading without experiencing significant structural damage or failure. The fatigue resistance of steel sheets is influenced by various factors such as material composition, treatment processes, and design considerations. Overall, steel sheets are known for their excellent fatigue performance, making them suitable for a wide range of applications where cyclic loading is involved.

- Q:What are the different types of steel sheet finishes for industrial applications?

- There are several different types of steel sheet finishes commonly used in industrial applications. These finishes are applied to steel sheets to enhance their appearance, protect against corrosion, improve paint adhesion, and provide other functional benefits. Some of the most common types of steel sheet finishes include: 1. Hot Rolled: This finish is achieved by passing the steel through a high-temperature furnace, followed by rapid cooling. It results in a rough, scaled surface that is suitable for applications where appearance is not a primary concern. 2. Cold Rolled: In this finish, the steel is processed at room temperature, resulting in a smooth and clean surface. Cold-rolled steel sheets are often used in applications where a high-quality surface finish is required. 3. Galvanized: Galvanizing involves coating the steel sheet with a layer of zinc to protect against corrosion. This finish is widely used in industries such as construction, automotive, and manufacturing, where durability and resistance to rust are crucial. 4. Electro-galvanized: Similar to galvanizing, electro-galvanizing also involves coating the steel with zinc. However, in this process, an electric current is used to deposit the zinc onto the steel surface, resulting in a thinner and more controlled coating. 5. Stainless Steel: Stainless steel sheets are known for their high resistance to corrosion, making them ideal for applications in harsh environments. They can be finished with a variety of surface textures, including brushed, mirror, and patterned finishes. 6. Pickled and Oiled: This finish involves removing any oxide scale from the steel surface using an acid solution, followed by applying an oil coating to prevent rust formation. Pickled and oiled steel sheets are commonly used in automotive and construction industries. 7. Painted: Steel sheets can also be finished with a layer of paint, which not only enhances their appearance but also provides additional protection against corrosion. The type of paint used can vary depending on the application and desired finish. It's important to note that these are just a few examples of steel sheet finishes used in industrial applications. Different finishes are chosen based on the specific requirements of the application, such as aesthetics, corrosion resistance, durability, and cost-effectiveness.

- Q:Can steel sheets be used for electrical conductivity?

- No, steel sheets are not typically used for electrical conductivity as they are not good conductors of electricity.

- Q:Can steel sheets be used in the medical industry?

- Yes, steel sheets can be used in the medical industry. They are often used in the manufacturing of medical equipment, surgical instruments, and medical furniture due to their durability, corrosion resistance, and ease of sterilization.

- Q:Are steel sheets suitable for interior ceiling panels?

- Yes, steel sheets are suitable for interior ceiling panels. They are durable, fire-resistant, and offer a sleek and modern look. Additionally, steel is easy to clean and maintain, making it a practical choice for ceiling panels in various indoor spaces.

- Q:Can steel sheets be used for HVAC applications?

- Indeed, HVAC applications can utilize steel sheets. In the realm of HVAC ductwork construction, steel sheets are frequently employed owing to their robustness, longevity, and fire-resistant qualities. These sheets can be effortlessly molded into diverse configurations and dimensions, tailored to the precise needs of HVAC systems. Moreover, steel sheets exhibit resistance against corrosion, a pivotal attribute in HVAC applications where moisture and condensation may manifest. All in all, steel sheets are a fitting material option for HVAC applications, given their mechanical characteristics and capacity to endure the demands of heating, ventilation, and air conditioning systems.

- Q:Can steel sheets be used for architectural facades?

- Indeed, architectural facades can make use of steel sheets. The reason for the widespread use of steel sheets in architectural facades is their durability, strength, and aesthetic charm. One can effortlessly mold steel sheets into various shapes and sizes, thereby enabling the creation of imaginative and distinctive designs. Furthermore, steel sheets can be coated or finished with different materials to not only enhance their appearance but also safeguard them from corrosion. In addition to all these advantages, steel is an environmentally friendly choice as it is recyclable and reusable, making it a sustainable material for architectural facades. Overall, architects and designers seeking to fashion visually stunning and long-lasting facades can rely on steel sheets, which provide a versatile and dependable option.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Hot Rolled Steel Chequered Skid Resistance Sheets Chequer Plates

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords