Hot Rolled Stainless Steel Coils Grade 304 NO.1 Finish Price

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 2000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

Products Description for Stainless Steel Coils/Sheets:

Product | stainless steel coils/plates/sheets | ||

Discharge Port | Any Port, China | ||

Size | Coils | Cold Rolled: | Thickness0.3-8mm,Width:280-2100mm |

Hot Rolled : | Thickness3-14mm,Width:650-2100mm | ||

Plates | Thickness2-80mm,Width:1500-3000mm | ||

Coil Weight | About 20 Tons | ||

Grade | 201,202,304/304L/304H,316/316L/316H,321/H,310S,409/L,430 etc. | ||

Technique | Hot Rolled/Cold Rolled | ||

Finish | 2B, BA, 2D, No1, No2, No4,NO.8,SB etc | ||

Edge | Mill Edge / Slitting Edge | ||

Package | In bundles, or as customer's requirement | ||

Place of Origin | Made in China | ||

MOQ | 20 Tons | ||

Application for Stainless Steel Coils/Sheets:

Boiler heat exchanger, machinery andpetroleum ,chemical industries, hardware fields,Food industry,construction material,kitchen utensils, building construction, medical equipment,chemical tank, pipe etc

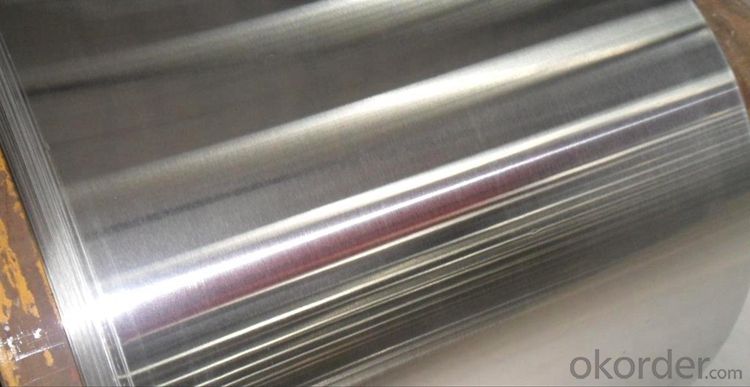

Detail picture for Stainless Steel Coils/Sheets

Packaging & Delivery for Stainless Steel Coils/Sheets:

Packaging Detail | Standard export packing or following customer's demand |

Delivery Time | Within 30-40 days after deposit or according to the order quantity |

FAQ for Stainless Steel Coils/Sheets:

Q: How can I get the samples?

A: If you need some samples to test ,please pay for the transportation freight of samples and our samples are free for you.

Q: How can I get your price list?

A: Please send us your email or fax and order information – Quantity, Specification (steel type, thickness, width, surface finish), then I can send you the price list.

- Q:Are stainless steel sheets resistant to saltwater?

- Yes, stainless steel sheets are highly resistant to saltwater. The corrosion-resistant properties of stainless steel make it an ideal material for applications exposed to saltwater environments.

- Q:What is the typical thickness range for stainless steel sheets?

- The typical thickness range for stainless steel sheets varies depending on the specific application and requirements. However, stainless steel sheets are commonly available in thicknesses ranging from 0.4mm to 6mm. Thinner sheets, such as those in the 0.4mm to 1mm range, are often used for decorative purposes or in applications that require flexibility. Thicker sheets, on the other hand, are commonly used in structural or industrial applications where strength and durability are crucial. It is important to note that these thickness ranges are not exhaustive, and customized stainless steel sheets can be manufactured to meet specific project requirements.

- Q:How do you remove adhesive from stainless steel sheets?

- One effective way to remove adhesive from stainless steel sheets is by applying a small amount of rubbing alcohol or acetone to a soft cloth and gently rubbing the adhesive residue. Another option is to use a mixture of warm water and mild soap, followed by scrubbing with a non-abrasive sponge or cloth. If the adhesive is particularly stubborn, using a commercial adhesive remover specifically designed for stainless steel can also be effective.

- Q:Are stainless steel sheets resistant to high temperatures?

- Stainless steel sheets are generally resistant to high temperatures, thanks to their excellent heat resistance properties. They are suitable for a wide range of applications that require withstanding high temperatures. This is due to the composition of stainless steel, which includes chromium, nickel, and other alloying elements. These elements create a protective oxide layer on the surface of the steel, acting as a barrier against oxidation and preventing corrosion or weakening at elevated temperatures. The structural integrity of stainless steel sheets remains intact even at temperatures up to approximately 1500°F (815°C). However, it is important to note that the temperature resistance may vary depending on the specific grade and thickness of the stainless steel sheet. To ensure accurate information for high-temperature applications, it is advisable to consult the manufacturer's specifications or seek professional advice.

- Q:Are stainless steel sheets suitable for outdoor sculptures or artwork?

- Yes, stainless steel sheets are highly suitable for outdoor sculptures or artwork. Stainless steel is known for its durability, corrosion resistance, and ability to withstand harsh weather conditions. It can maintain its appearance and integrity even when exposed to rain, sun, and other environmental factors. Additionally, stainless steel offers a sleek and modern aesthetic, making it a popular choice for outdoor sculptures or artwork.

- Q:What are the different types of stainless steel sheet finishes?

- There are several types of stainless steel sheet finishes, including No. 1, 2B, No. 4, BA, and satin.

- Q:Are stainless steel sheets suitable for elevator flooring?

- Yes, stainless steel sheets are suitable for elevator flooring. They are durable, resistant to corrosion, easy to clean, and provide a sleek and modern look that complements the interior design of elevators.

- Q:How do I prevent stress corrosion cracking on stainless steel sheets?

- To prevent stress corrosion cracking on stainless steel sheets, there are several measures you can take: 1. Choose the right stainless steel grade: Use a stainless steel grade that is resistant to stress corrosion cracking (SCC). Common grades like 304 and 316 have good resistance to SCC, but some specific applications may require higher alloyed grades such as duplex or super duplex stainless steels. 2. Avoid exposure to corrosive environments: Limit the exposure of stainless steel sheets to environments that are known to cause stress corrosion cracking, such as chloride-rich or acidic environments. If exposure cannot be avoided, consider using protective coatings or barriers to shield the stainless steel from these corrosive elements. 3. Control applied stress levels: Avoid subjecting the stainless steel sheets to excessive mechanical or thermal stresses. High tensile stresses can promote the initiation and propagation of stress corrosion cracking. Proper design and fabrication techniques should be employed to ensure even stress distribution and minimize stress concentrations. 4. Maintain proper surface condition: Ensure that the stainless steel sheets are free from surface contamination or defects that can act as initiation sites for stress corrosion cracking. Regular cleaning and inspection of the sheets to remove any contaminants or corrosion products is crucial. 5. Use inhibitors or cathodic protection: In certain cases where exposure to corrosive environments is unavoidable, the use of corrosion inhibitors or implementing cathodic protection techniques can help mitigate stress corrosion cracking. These methods work by reducing the corrosive activity on the stainless steel surface. 6. Proper handling and storage: During transportation and storage, care should be taken to avoid excessive bending, vibration, or exposure to corrosive substances. Stainless steel sheets should be stored in a clean and dry environment to prevent any potential surface contamination. Overall, a combination of material selection, environmental control, stress management, surface maintenance, and proper handling can effectively prevent stress corrosion cracking on stainless steel sheets. It is advisable to consult with material experts or engineers to analyze the specific application requirements and recommend the most appropriate preventive measures.

- Q:Can stainless steel sheets be used for elevator wall panels?

- Elevator wall panels can indeed be constructed using stainless steel sheets. The utilization of stainless steel as a material for elevator interiors is highly favored due to its robustness, cleanliness, and aesthetic attractiveness. It imparts a sleek and contemporary appearance that enhances the overall look of the elevator. Furthermore, stainless steel is resistant to corrosion, staining, and scratching, rendering it suitable for high-traffic areas such as elevators. Moreover, it is effortless to clean and maintain, guaranteeing that the elevator walls remain in optimal condition for an extended period. What's more, stainless steel sheets can be tailored to meet specific design requirements and preferences, offering a plethora of finishes, patterns, and colors that can harmonize with the building or elevator's design. Ultimately, stainless steel sheets prove to be a superb option for elevator wall panels.

- Q:Can stainless steel sheets be used for flooring?

- Certainly, flooring can indeed be made using stainless steel sheets. Stainless steel, being a sturdy and adaptable substance, possesses resistance against corrosion, stains, and scratches, thereby rendering it fitting for areas with heavy foot traffic. It is frequently employed in commercial and industrial environments like hospitals, kitchens, and food processing plants, where cleanliness and hygiene hold paramount importance. Stainless steel flooring imparts a polished and contemporary appearance, is effortless to clean and maintain, and can endure substantial loads and extreme temperatures. Furthermore, stainless steel sheets can be personalized to suit any area and can be installed with different finishes to augment slip resistance.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Hot Rolled Stainless Steel Coils Grade 304 NO.1 Finish Price

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 2000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords