Hot Rolled Stainless Steel Coils 316 NO.1 Finish

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 23 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

Products Description for Stainless Steel Coils/Sheets:

Product | stainless steel coils/plates/sheets | ||

Discharge Port | Any Port, China | ||

Size | Coils | Cold Rolled: | Thickness0.3-8mm,Width:280-2100mm |

Hot Rolled : | Thickness3-14mm,Width:650-2100mm | ||

Plates | Thickness2-80mm,Width:1500-3000mm | ||

Coil Weight | About 20 Tons | ||

Grade | 201,202,304/304L/304H,316/316L/316H,321/H,310S,409/L,430 etc. | ||

Technique | Hot Rolled/Cold Rolled | ||

Finish | 2B, BA, 2D, No1, No2, No4,NO.8,SB etc | ||

Edge | Mill Edge / Slitting Edge | ||

Package | In bundles, or as customer's requirement | ||

Place of Origin | Made in China | ||

MOQ | 20 Tons | ||

Specifications for Stainless Steel Coils/Sheets:

Name: stainless steel coils/plates/sheets

Discharge Port: Any Port, China

Cold Rolled Size: Thickness0.3-8mm,Width:280-2100mm

Hot Rolled Size: Thickness3-14mm,Width:650-2100mm

Hot Rolled/Cold Rolled Plates : Thickness2-80mm,Width:1500-3000mm

Coil Weight: About 20 Tons

Grade: 201,202,304/304L/304H, 316/316L/316H, 409/L,430 etc.

Technique: Hot Rolled/Cold Rolled

Finish:2B, BA, 2D, No1, No2 etc

Edge: Mill Edge / Slitting Edge

Packaging: In bundles, or as customer's requirement

Place of Origin: Made in China

MOQ: 20 Tons

Payment Terms: 100% LC at sight, or 100%TT in advance

Delivery Time: With 30-40 days after deposit

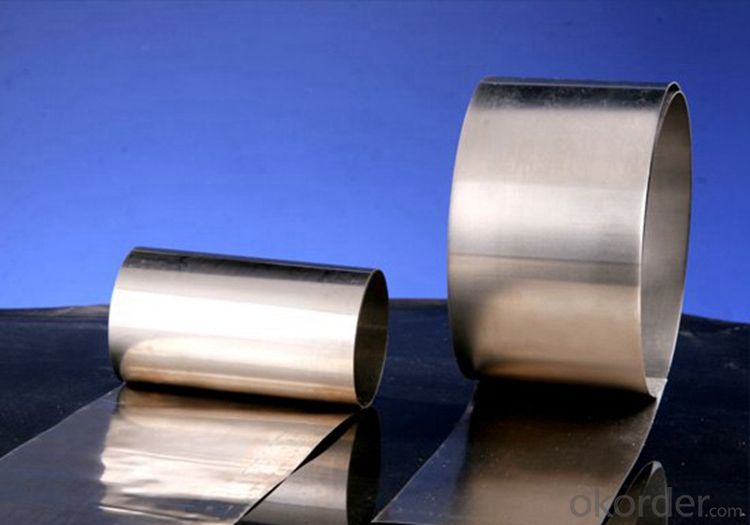

Detail picture for Stainless Steel Coils/Sheets

Features of Stainless Steel Coils

(1)Good ductility

(2)Good corrosion resistance

(3)Excellent abrasion resistance and fatigue strength

(4)Good weldability

(5)Oxidation resistant performance

(6)Excellent in high temperature

Payment&Delivery for Stainless Steel Coils/Sheets:

Payment Terms | 100% LC at sight,or 30%TT in advance, balance against B/L copy |

Delivery Time | With 30-40 days after deposit |

Price Terms | Ex-Work, FOB, CNF, CFR, CIF,etc |

Application of Stainless Steel Coils

Boiler heat exchanger, machinery andpetroleum ,chemical industries, hardware fields,Food industry,construction material,kitchen utensils, building construction, medical equipment,chemical tank, pipe etc

FAQ for Stainless Steel Coils/Sheets:

Q: How long is the delivery time?

A: Normally 30-40 days, but mostly according to the specific requirements or the quantity

Q: Could you send me sample?

A: We can supply you with the sample for free, but the delivery charges will be covered by customers.

- Q:What does "stainless steel plate" 6.0*1500c mean?

- 1500 can be expressed as stainless steel width.Usually, the Rongchang self lubrication stainless steel plate is expressed in this way. The Rongchang self lubricating stainless steel plate is made up of 3 layers

- Q:Can stainless steel sheets be used in marine environments?

- Yes, stainless steel sheets can be used in marine environments. Stainless steel is highly resistant to corrosion, making it suitable for marine applications where it will be exposed to saltwater and high humidity. It is commonly used in marine vessels, offshore platforms, and other structures that require durability and resistance to rust and corrosion.

- Q:What are the different types of stainless steel sheet grades available?

- There are several different types of stainless steel sheet grades available, including 304, 316, 430, and 201. Each grade has its own unique properties and applications, making them suitable for various industries and purposes.

- Q:Are stainless steel sheets suitable for medical equipment or devices?

- Yes, stainless steel sheets are commonly used in the manufacturing of medical equipment or devices due to their excellent corrosion resistance, durability, ease of cleaning, and ability to withstand sterilization processes.

- Q:What is the impact resistance of stainless steel sheets?

- Due to its unique properties and composition, stainless steel sheets exhibit a high level of impact resistance. This refers to their ability to withstand sudden loads or forces without suffering permanent deformation or breakage. The material possesses exceptional toughness and durability, rendering it highly resistant to impact. The impact resistance of stainless steel sheets can be attributed to their high tensile strength and ductility. This alloy, which contains iron, chromium, and other elements, contributes to its strength and corrosion resistance. The presence of chromium forms a protective oxide layer on the steel's surface, preventing easy rusting or corrosion. Moreover, stainless steel sheets are available in various grades, each with its own composition and properties. The most commonly utilized grade for impact-resistant applications is 304 stainless steel, which offers good resistance against impact and finds widespread use in industries such as construction, automotive, and aerospace. The impact resistance of stainless steel sheets also depends on their thickness. Thicker sheets tend to possess greater impact resistance due to their increased mass and structural integrity. However, even thinner stainless steel sheets can provide significant impact resistance owing to the inherent strength and toughness of the material. In practical applications, stainless steel sheets are frequently employed in environments where impact resistance is vital, such as in the manufacture of machinery, equipment, and structures subject to high loads or potential impacts. They can endure heavy impacts without cracking, fracturing, or deforming, thereby ensuring the integrity and longevity of the final product. Overall, stainless steel sheets exhibit excellent impact resistance, making them a preferred choice in various industries. Their high strength, corrosion resistance, and durability render them suitable for applications where resistance to impact is crucial.

- Q:Are stainless steel sheets good for high-temperature applications?

- Yes, stainless steel sheets are excellent for high-temperature applications due to their unique properties such as high heat resistance, corrosion resistance, and the ability to maintain their strength and integrity even at elevated temperatures.

- Q:How do you prevent pitting corrosion on stainless steel sheets?

- To prevent pitting corrosion on stainless steel sheets, it is important to maintain a clean and dry surface, avoid exposure to corrosive environments or chemicals, and promptly clean off any contaminants or deposits. Additionally, applying a protective coating or passivation treatment can help enhance the corrosion resistance of the stainless steel sheets. Regular inspections and maintenance are also crucial to detect and address any signs of pitting corrosion early on.

- Q:What are the different types of edge finishes for stainless steel sheets?

- There are several different types of edge finishes that can be applied to stainless steel sheets. These finishes are designed to enhance the appearance and functionality of the edges while also providing protection against corrosion and damage. 1. Mill Finish: This is the most basic type of edge finish, where the edges are left as they come from the mill. It is a straight, unfinished edge without any additional treatment or polishing. 2. Deburred Edge: In this type of finish, the rough edges are smoothed out and deburred using abrasive materials. This helps to eliminate sharp edges and burrs, making the sheet safer to handle and preventing potential injuries. 3. Rounded Edge: A rounded edge finish involves milling or machining the edges to create a curved or rounded profile. This type of finish is commonly used in applications where safety is a concern, as it reduces the risk of cuts or injuries caused by sharp edges. 4. Beveled Edge: A beveled edge finish involves cutting or grinding the edges at an angle to create a sloped or chamfered profile. This type of finish is often used for aesthetic purposes, as it adds a decorative element to the sheet and can create a smooth transition between different surfaces. 5. Polished Edge: In this type of finish, the edges of the stainless steel sheet are polished to a high shine using abrasive materials or polishing compounds. This produces a smooth, reflective surface that enhances the overall appearance of the sheet and gives it a more finished look. 6. Brushed Edge: A brushed edge finish involves applying a brushed texture to the edges of the stainless steel sheet. This is achieved by using abrasive materials or brushes to create a consistent pattern of fine lines or scratches. The brushed edge finish can provide a unique and contemporary look to the sheet. These different types of edge finishes for stainless steel sheets offer various benefits and can be chosen based on the specific requirements of the application. Whether it's for safety, aesthetics, or functionality, selecting the right edge finish can greatly enhance the performance and visual appeal of stainless steel sheets.

- Q:Are stainless steel sheets suitable for architectural wire mesh?

- Yes, stainless steel sheets are suitable for architectural wire mesh. Stainless steel is a durable and corrosion-resistant material, making it ideal for outdoor applications. It provides strength and stability to the wire mesh, ensuring longevity and aesthetic appeal in architectural designs.

- Q:Can stainless steel sheets be used for brewery equipment?

- Yes, stainless steel sheets can be used for brewery equipment. Stainless steel is a popular choice for brewery equipment due to its corrosion resistance, durability, and hygienic properties. It is resistant to the chemicals and acids commonly used in brewing processes and does not react with beer, ensuring the taste and quality of the final product. Stainless steel sheets can be used to fabricate various brewery equipment such as fermentation tanks, bright tanks, mash tuns, hot liquor tanks, and piping systems. Additionally, stainless steel is easy to clean and maintain, making it an ideal material for brewery equipment where sanitation is crucial.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Hot Rolled Stainless Steel Coils 316 NO.1 Finish

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 23 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords