Hot Rolled Stainless Steel Coils 316 NO.1 Finish From China

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 2000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

Products Description for Stainless Steel Coils/Sheets:

Name: stainless steel coils/plates/sheets

Discharge Port: Any Port, China

Cold Rolled Size: Thickness0.3-8mm,Width:280-2100mm

Hot Rolled Size: Thickness3-14mm,Width:650-2100mm

Hot Rolled/Cold Rolled Plates : Thickness2-80mm,Width:1500-3000mm

Coil Weight: About 20 Tons

Grade: 201,202,304/304L/304H, 316/316L/316H, 409/L,430 etc.

Technique: Hot Rolled/Cold Rolled

Finish:2B, BA, 2D, No1, No2 etc

Edge: Mill Edge / Slitting Edge

Packaging: In bundles, or as customer's requirement

Place of Origin: Made in China

MOQ: 20 Tons

Payment Terms: 100% LC at sight, or 100%TT in advance

Delivery Time: With 30-40 days after deposit

Application for Stainless Steel Coils/Sheets:

Boiler heat exchanger, machinery andpetroleum ,chemical industries, hardware fields,Food industry,construction material,kitchen utensils, building construction, medical equipment,chemical tank, pipe etc

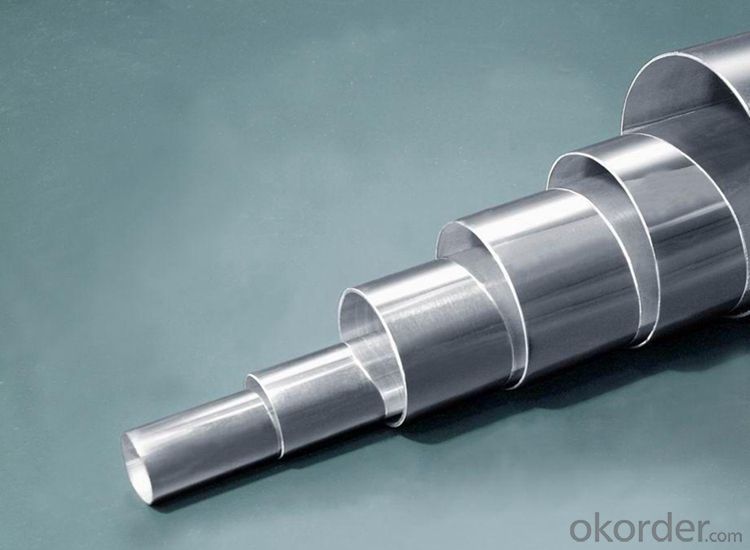

Detail picture for Stainless Steel Coils/Sheets

Packaging & Delivery for Stainless Steel Coils/Sheets:

Packaging Detail | Standard export packing or following customer's demand |

Delivery Time | Within 30-40 days after deposit or according to the order quantity |

FAQ for Stainless Steel Coils/Sheets:

Q:What are the advantages of your company ?

A: We have many professionals, technical personnel, more competitive prices and best after-dales service than other stainless steel companies.

Q:Can you arrange the shipment ?

A: Sure we can help you with the shipment. We have forwarders who have cooperated with us for many years.

- Q:Are stainless steel sheets suitable for chemical tanks?

- Yes, stainless steel sheets are suitable for chemical tanks. Stainless steel is known for its excellent resistance to corrosion, making it an ideal material for storing and transporting chemicals. It has high strength and durability, making it capable of withstanding harsh chemicals and extreme temperatures. Stainless steel also has a smooth, non-porous surface, which prevents the absorption of chemicals and facilitates easy cleaning. Additionally, stainless steel is non-reactive, meaning it does not react with most chemicals, ensuring the integrity of the stored substances. Overall, stainless steel sheets are a reliable and popular choice for chemical tanks due to their resistance to corrosion, strength, durability, and non-reactivity.

- Q:How do you attach stainless steel sheets to a wall?

- To attach stainless steel sheets to a wall, you can use a combination of adhesive and mechanical fasteners. First, ensure that the wall is clean and free from any debris or grease. Apply a strong construction adhesive to the back of the stainless steel sheet, spreading it evenly across the surface. Then, press the sheet firmly against the wall and hold it in place for a few minutes to allow the adhesive to bond. Additionally, use mechanical fasteners such as screws or nails to secure the stainless steel sheet to the wall, placing them along the edges and in the center of the sheet for added support and stability.

- Q:What is the thermal expansion coefficient of stainless steel sheets?

- The thermal expansion coefficient of stainless steel sheets typically ranges from 10.5 to 12.5 x 10^-6 per degree Celsius.

- Q:How do I bend or form stainless steel sheets?

- To bend or form stainless steel sheets, you can follow these steps: 1. Choose the appropriate stainless steel grade: Stainless steel comes in various grades, each with specific properties. Select the grade that best suits your project's requirements, considering factors like corrosion resistance, strength, and formability. 2. Use the right tools: To bend stainless steel sheets, you will need specific tools such as a hydraulic press brake or a metal bending machine. These tools apply force evenly to achieve precise and consistent bends. Make sure to use tools that are designed for stainless steel to avoid damaging the material. 3. Prepare the stainless steel sheet: Before bending, ensure that the stainless steel sheet is clean and free from any dirt or debris. Additionally, mark the desired bending lines on the sheet using a pencil or tape to guide you during the process. 4. Determine the bending angle and radius: Determine the angle and radius of the bend you want to achieve. This will depend on the specific requirements of your project. Use a protractor or a template to measure and mark the desired angles accurately. 5. Secure the stainless steel sheet: To prevent movement or slipping during the bending process, securely clamp the stainless steel sheet to the bending tool or machine. This will ensure stability and accuracy during the bending process. 6. Apply pressure gradually: Start the bending process slowly and gradually increase the pressure. This prevents the stainless steel sheet from cracking or warping. Monitor the bending carefully to ensure that the desired shape is achieved without any defects or deformation. 7. Repeat if necessary: If you need to create multiple bends or complex shapes, repeat the process as required. Ensure that each bend is carefully measured and aligned with the previous bends to achieve a consistent and accurate result. 8. Finishing touches: After bending the stainless steel sheet, remove any residual marks or burrs using a file or sandpaper. This will give your finished product a smooth and polished appearance. Remember, bending stainless steel sheets can be challenging, especially for thicker gauges or harder grades. It is advisable to practice on scrap pieces or seek professional assistance if you are unsure or lack experience in working with stainless steel.

- Q:Can stainless steel sheets be etched with designs?

- Yes, stainless steel sheets can be etched with designs.

- Q:What is the electrical conductivity of stainless steel sheets?

- The electrical conductivity of stainless steel sheets is relatively low compared to other metals, such as copper or aluminum.

- Q:Can stainless steel sheets be used for decorative staircases?

- Yes, stainless steel sheets can be used for decorative staircases. Stainless steel is a versatile material that offers a modern and sleek appearance, making it an ideal choice for creating decorative staircases. Its durability, resistance to corrosion, and ability to be shaped into various designs make stainless steel sheets a popular option for adding a stylish touch to staircases.

- Q:What are the benefits of using etched stainless steel sheets in signage?

- Using etched stainless steel sheets in signage comes with numerous advantages. Firstly, these sheets are incredibly durable and long-lasting due to stainless steel's resistance to corrosion, rust, and fading. This makes them perfect for outdoor signage that is exposed to harsh weather conditions. Secondly, etched stainless steel sheets provide a sleek and professional look. Through the process of etching, intricate designs, logos, and text can be permanently engraved onto the surface of the stainless steel. This results in a visually appealing finish that adds sophistication to any signage. Additionally, etched stainless steel sheets are highly customizable, allowing them to meet specific design requirements. This versatility makes them suitable for a wide range of signage applications such as architectural signage, company logos, directional signs, or wayfinding systems. They can be tailored to match any style or branding. Moreover, stainless steel is easy to clean and maintain. Simply wiping it down with a cloth or using mild soap and water will keep the signage in pristine condition for an extended period. This low maintenance requirement is particularly advantageous for outdoor signage that may require regular cleaning. Lastly, etched stainless steel sheets offer excellent visibility. By filling the engraved designs on the stainless steel surface with paint or other materials, the signage becomes highly visible even from a distance or in low light conditions. This enhanced visibility ensures that the intended message or information is effectively communicated to the target audience. In conclusion, the use of etched stainless steel sheets in signage provides durability, a professional appearance, customization options, easy maintenance, and excellent visibility. These advantages have made etched stainless steel sheets a popular choice for signage applications across various industries.

- Q:Stainless steel plate how to distinguish between good and bad, there are several thick?

- 1. identification of imported or steel ordered stainless steel materials, usually only in accordance with the import or steel quality certificate, check the steel or packaging on the mark can be.The certificate of quality is the confirmation and guarantee of the inspection result of the product by the supplier. Therefore, the certificate of quality not only indicates the name, specifications, delivery number, weight and delivery status of the materials, but also the entire inspection results of the required guarantee items.

- Q:How do you cut intricate designs in stainless steel sheets?

- One effective way to cut intricate designs in stainless steel sheets is by using a laser cutting machine. Laser cutting technology allows for precise and intricate cuts, making it ideal for complex designs. The laser beam melts, burns, or vaporizes the material, resulting in a clean and accurate cut without the need for additional finishing. This method ensures high-quality and precise cuts in stainless steel sheets.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Hot Rolled Stainless Steel Coils 316 NO.1 Finish From China

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 2000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords