Hot Rolled Stainless Steel 316L NO.1 Finish

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 18 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

Products Description for Stainless Steel

Name: stainless steel coils/plates/sheets

Discharge Port: Any Port, China

Cold Rolled Size: thickness0.3-8mm,Width:280-2100mm

Hot Rolled Size: Thickness3-14mm,Width:650-2100mm

Hot Rolled/Cold Rolled Plates : Thickness2-80mm,Width:1500-3000mm

Coil Weight: About 20 Tons

Grade: 201,202,304/304L/304H, 316/316L/316H, 409/L,430 etc.

Technique: Hot Rolled/Cold Rolled

Finish:2B, BA, 2D, No1, No2 etc

Edge: Mill Edge / Slitting Edge

Packaging: In bundles, or as customer's requirement

Place of Origin: Made in China

MOQ: 20 Tons

Payment Terms: 100% LC at sight, or 100%TT in advance

Delivery Time: With 30-40 days after deposit

Payment&Delivery

Payment Terms | 100% LC at sight,or 30%TT in advance, balance against B/L copy |

Delivery Time | With 30-40 days after deposit |

Price Terms | Ex-Work, FOB, CNF, CFR, CIF,etc |

Application of Stainless Steel Coils

(1) Boiler heat exchanger,

(2) Chemical industries,

(3) Hardware fields,

(4) Construction material,

(5) Kitchen utensils,

(6) Building construction,

(7) Medical equipment,

(8) chemical tank,

(9) pipe etc

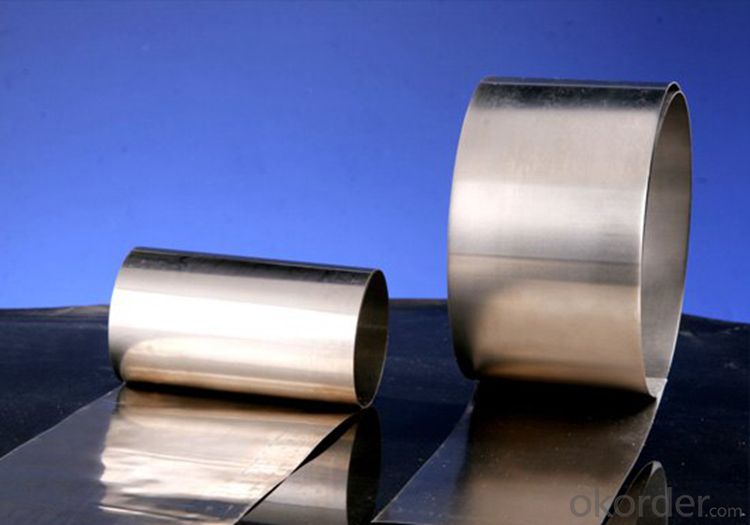

Detail picture for Stainless Steel

FAQ for Stainless Steel

Q: How long is the delivery time?

A: Normally 30-40 days, but mostly according to the specific requirements or the quantity

Q: Could you send me sample?

A: We can supply you with the sample for free, but the delivery charges will be covered by customers.

- Q:Are stainless steel sheets resistant to caustic soda?

- Yes, stainless steel sheets are generally resistant to caustic soda.

- Q:What are the different types of edge profiles for stainless steel sheets?

- There are several different types of edge profiles that can be applied to stainless steel sheets, depending on the desired aesthetic and functional requirements. Some of these edge profiles include: 1. Square Edge: This is the most basic and common edge profile for stainless steel sheets. It features a straight, square edge without any additional shaping or finishing. 2. Beveled Edge: A beveled edge is achieved by cutting and shaping the edge of the stainless steel sheet at an angle. This profile adds a slight slope or chamfer to the edge, giving it a more refined and polished appearance. 3. Rounded Edge: Also known as a bullnose edge, this profile involves rounding off the sharp edges of the stainless steel sheet. It creates a smooth and curved edge that minimizes the risk of injuries from sharp corners. 4. Full Radius Edge: This edge profile involves creating a complete semicircular or rounded edge along the length of the stainless steel sheet. It offers a more pronounced curved appearance compared to a rounded edge. 5. Ogee Edge: An ogee edge profile features a double curve, with one concave curve followed by a convex curve. It adds an elegant and decorative touch to the stainless steel sheet, making it suitable for applications that require a more ornamental look. 6. Dupont Edge: This edge profile is characterized by a straight edge with a small bevel on the top and bottom sides of the sheet. It offers a sleek and modern appearance, often used in contemporary design applications. 7. Knife Edge: A knife edge profile involves sharpening the edge of the stainless steel sheet to create a thin, sharp edge. This profile is commonly used for applications where a precise and clean-cut appearance is desired. These are just a few examples of the different edge profiles available for stainless steel sheets. The choice of edge profile depends on the intended use, style preferences, and specific requirements of the project at hand.

- Q:Are stainless steel sheets resistant to staining?

- Stainless steel sheets possess a remarkable resistance to staining due to their high chromium content. This abundance of chromium creates a protective layer on the metal's surface, referred to as the passive layer, which effectively prevents the steel from interacting with oxygen and moisture in the surroundings. Consequently, stainless steel becomes immune to rust and corrosion. Moreover, the smooth and non-porous nature of stainless steel surfaces makes it challenging for stains to infiltrate and cling onto the material. Although stainless steel sheets may eventually exhibit some signs of staining, they can be effortlessly cleaned and restored to their original condition with minimal exertion. Consequently, stainless steel sheets are widely favored in various settings, including kitchens, hospitals, and industrial environments, where stain resistance is of utmost importance.

- Q:What are the different types of stainless steel sheet finishes?

- A variety of stainless steel sheet finishes are accessible, each possessing distinctive traits and appearances. Some of the most prevalent finishes comprise: 1. No.1 Finish: Termed "hot rolled annealed and pickled" (HRAP), this finish is the most fundamental and widely employed. It exhibits a dull, coarse surface with visible grain lines. 2. No.2B Finish: By cold rolling the stainless steel sheet and subsequently annealing it in a controlled environment, this finish is achieved. It possesses a smooth, reflective surface with a slight haze. 3. No.2D Finish: Similar to No.2B, this finish is acquired through cold rolling and annealing. However, it has a marginally rougher surface and is commonly utilized for applications not necessitating a highly reflective finish. 4. No.3 Finish: By meticulously polishing the stainless steel sheet using abrasive belts or brushes, this finish is accomplished. It presents a semi-reflective surface with a grainy appearance. 5. No.4 Finish: Termed "brushed finish," this finish is attained by utilizing fine abrasive belts or brushes to create a consistent, linear grain pattern on the surface. It exhibits a matte appearance and is typically employed in architectural and decorative applications. 6. No.6 Finish: Through further polishing the stainless steel with finer abrasives, this finish is realized, resulting in a smoother and more reflective surface. 7. No.7 Finish: Analogous to No.6, this finish is accomplished by employing even finer abrasives, culminating in a highly reflective surface with a mirror-like appearance. 8. No.8 Finish: Also known as the "mirror finish," this represents the highest level of polish achievable on stainless steel. It showcases a flawless, reflective surface that is frequently utilized in decorative and high-end applications. Besides these conventional finishes, there are also specialized finishes obtainable, such as embossed, patterned, or colored finishes, which can further augment the aesthetic allure of stainless steel sheets. The selection of a finish relies on the specific application and desired appearance, with each finish offering its own distinct advantages and characteristics.

- Q:304 stainless steel plate 1*1219*C what do you mean?

- 304 is the most widely used stainless steel, heat-resistant steel. For food production equipment, general chemical equipment, nuclear energy and so on304 stainless steel chemical composition

- Q:Can stainless steel sheets be bent?

- Yes, stainless steel sheets can be bent. However, the degree of bendability depends on the thickness and grade of the stainless steel.

- Q:Are stainless steel sheets resistant to chemicals?

- Generally, chemicals do not pose a problem for stainless steel sheets. Stainless steel is famous for its ability to resist corrosion, which is why it is widely used in industries like chemical processing, pharmaceuticals, and food processing. The presence of elements like chromium and nickel in stainless steel forms a protective layer on its surface, preventing most chemicals from penetrating. However, it's important to note that the resistance to chemicals may vary depending on the grade and composition of the stainless steel used. In highly aggressive environments or when dealing with specific chemicals, it's advisable to consult a materials engineer or refer to compatibility charts to ensure the best stainless steel grade is chosen.

- Q:Can stainless steel sheets be used for food storage containers?

- Yes, stainless steel sheets can be used for food storage containers. Stainless steel is a safe and hygienic material for storing food as it is non-reactive, resistant to corrosion, and does not leach any harmful substances into the food. It is commonly used in commercial kitchens and food processing industries due to its durability and ease of cleaning.

- Q:Who knows the production process of stainless steel plate?

- Stainless steel surface process:Stainless steel has a variety of surface processing to broaden its application areas, different surface processing makes the surface of stainless steel different, making it unique in the application.The corrosion environment requires smooth surface for smooth surface is not easy to fouling. Deposition of dirt can make stainless steel rusty and even cause corrosion.In the spacious lobby, stainless steel is the most commonly used decorative materials for the elevator decoration, although the surface of the fingerprint can erase, but affect the appearance, it is best to use the appropriate surface to prevent leaving fingerprints.

- Q:What is the maximum size available for stainless steel sheets?

- The maximum size of stainless steel sheets depends on various factors, including the supplier's manufacturing capabilities and the customer's specific requirements. Standard sizes for stainless steel sheets can vary based on the thickness and grade of the material. Typically, stainless steel sheets can be obtained in standard sizes ranging from 4 feet by 8 feet (1220mm x 2440mm) to larger dimensions like 5 feet by 10 feet (1524mm x 3048mm). However, it is also possible to find custom sizes or oversized sheets that surpass these dimensions, especially for industrial or specialized purposes. It is important to consider that larger sizes may present additional challenges, such as increased weight and difficulties in handling. Furthermore, the availability of specific sizes may differ among suppliers. Therefore, it is advisable to consult with a stainless steel sheet supplier or manufacturer to ascertain the exact maximum size options they offer.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Hot Rolled Stainless Steel 316L NO.1 Finish

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 18 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords