Hot Rolled MS Mild JIS Steel U Channels for Strcutures

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 200000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

OKorder is offering Hot Rolled MS Mild JIS Steel U Channels for Strcutures at great prices with worldwide shipping. Our supplier is a world-class manufacturer of steel, with our products utilized the world over. OKorder annually supplies products to European, North American and Asian markets. We provide quotations within 24 hours of receiving an inquiry and guarantee competitive prices.

Product Applications:

Hot Rolled MS Mild JIS Steel U Channels for Strcutures are ideal for structural applications and general fabricating. The steel u channel can be applied to construction of warehouses, workshops, sport stadiums and car parks etc. In details, the steel u channel belongs to carbon structural steel which is applied to in the field of construction and machinery. The steel u channel is usually used for arch-itechtural structure, and they could be welded in order to support or hang a vari-ety of facilities. They are also usually used in combination with I beam. Generally,the steel u channel must possess perfect welding property, riveting property and mechanical property and so on.

Product Advantages:

Hot Rolled MS Mild JIS Steel U Channels for Strcutures are durable, strong, and resists corrosion.

Main Product Features:

· Premium quality

· Prompt delivery & seaworthy packing (7-10 days after receiving deposit)

· Corrosion resistance

· Can be recycled and reused

· Mill test certification

· Professional Service

· Competitive pricing

Product Specifications:

Steel U Channel Details:

Minimum Order Quantity: 25 Tons Unit: m.t. Loading Port: Xingang Port

Supply Ability: 1000 Tons Per Day Payment Terms: TT or L/C

Product Description:

Specifications of Steel U Channel:

Standard Applied: GB Standard, EN Standard(UPN), JIS Standard

Sizes: 50mm to 300mm

Material Grade: Q235B, Q345B, S235JR, SS400, ASTM A36

As shown in the figure:

| JIS U CHANNEL | Standard h | Sectional b | Dimension s | t | Mass: Kg/m |

| (mm) | (mm) | (mm) | (mm) | ||

| 50x25 | 50 | 25 | 3.0 | 6.00 | 2.37 |

| 75X40 | 75 | 40 | 3.8 | 7.00 | 5.30 |

| 75X40 | 75 | 40 | 4.0 | 7.00 | 5.60 |

| 75X40 | 75 | 40 | 4.5 | 7.00 | 5.85 |

| 75X40 | 75 | 40 | 5.0 | 7.00 | 6.92 |

| 100X50 | 100 | 50 | 3.8 | 6.00 | 7.30 |

| 100X50 | 100 | 50 | 4.2 | 6.00 | 8.03 |

| 100X50 | 100 | 50 | 4.5 | 7.50 | 8.97 |

| 100X50 | 100 | 50 | 5.0 | 7.50 | 9.36 |

| 125X65 | 125 | 65 | 5.2 | 6.80 | 11.66 |

| 125X65 | 125 | 65 | 5.3 | 6.80 | 12.17 |

| 125X65 | 125 | 65 | 5.5 | 8.00 | 12.91 |

| 125X65 | 125 | 65 | 6.0 | 8.00 | 13.40 |

| 150x75 | 150 | 75 | 5.5 | 7.30 | 14.66 |

| 150x75 | 150 | 75 | 5.7 | 10.00 | 16.71 |

| 150x75 | 150 | 75 | 6.0 | 10.00 | 17.90 |

| 150x75 | 150 | 75 | 6.5 | 10.00 | 18.60 |

FAQ:

Q1: Why buy Materials & Equipment from OKorder.com?

A1: All products offered byOKorder.com are carefully selected from China's most reliable manufacturing enterprises. Through its ISO certifications, OKorder.com adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

Q3: How soon can we receive the product after purchase?

A3: Within three days of placing an order, we will begin production. The specific shipping date is dependent upon international and government factors, but is typically 7 to 10 workdays.

Q4: What makes stainless steel stainless?

A4: Stainless steel must contain at least 10.5 % chromium. It is this element that reacts with the oxygen in the air to form a complex chrome-oxide surface layer that is invisible but strong enough to prevent further oxygen from "staining" (rusting) the surface. Higher levels of chromium and the addition of other alloying elements such as nickel and molybdenum enhance this surface layer and improve the corrosion resistance of the stainless material.

Q5: Can stainless steel rust?

A5: Stainless does not "rust" as you think of regular steel rusting with a red oxide on the surface that flakes off. If you see red rust it is probably due to some iron particles that have contaminated the surface of the stainless steel and it is these iron particles that are rusting. Look at the source of the rusting and see if you can remove it from the surface.

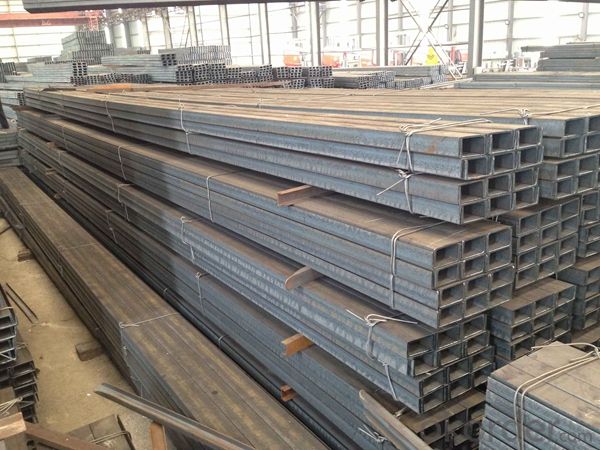

Images:

- Q:Can steel channels be used for equipment platforms?

- Indeed, equipment platforms can utilize steel channels. The robustness and endurance of steel channels make them prevalent in construction and industrial settings. They furnish a solid foundation for supporting weighty machinery on platforms, guaranteeing stability and security. Furthermore, steel channels can be effortlessly tailored and crafted to fulfill precise platform prerequisites, encompassing dimensions and load-bearing capabilities.

- Q:What are the different surface treatments available for steel channels in corrosive environments?

- There are several surface treatments available for steel channels in corrosive environments. These treatments are designed to provide a protective layer on the surface of the steel, preventing corrosion and extending the lifespan of the channels. One commonly used surface treatment is hot-dip galvanizing. In this process, the steel channels are immersed in a bath of molten zinc, which forms a zinc-iron alloy coating on the surface. This coating acts as a barrier against corrosive elements, protecting the steel from rust and corrosion. Another option is electroplating, which involves the deposition of a thin layer of metal onto the surface of the steel channels through an electrochemical process. Common metals used for electroplating include zinc, nickel, and chromium. Each metal provides its own unique corrosion resistance properties, and the choice of electroplating material depends on the specific corrosive environment. Additionally, steel channels can be treated with organic coatings such as paints or powder coatings. These coatings form a protective layer over the steel, acting as a barrier against moisture and corrosive chemicals. Paints can be applied through spraying, brushing, or dipping, while powder coatings involve the application of a dry powder that is then heated to form a protective coating. In some cases, steel channels can also undergo a process called passivation. Passivation involves the use of acid solutions to remove surface impurities and create a protective oxide layer on the steel surface. This oxide layer enhances the resistance of the steel to corrosion. It is important to consider the specific corrosive environment and the desired level of protection when selecting a surface treatment for steel channels. Consulting with corrosion experts or professionals in the steel industry can help in determining the most suitable treatment option for a particular application.

- Q:Can steel channels be used in earthquake-prone areas?

- Yes, steel channels can be used in earthquake-prone areas. Steel is known for its strength and durability, making it a suitable material for construction in areas prone to earthquakes. Steel channels provide structural support and can withstand seismic forces, making them an ideal choice for earthquake-resistant building designs. Additionally, steel's flexibility allows it to absorb and dissipate energy during earthquakes, reducing the risk of structural damage.

- Q:How is the channel steel set on the wall?

- There are two ways, one is to open the wall, the two is to punch on the wall, the channel is also punched, and then use the Peng bolt

- Q:In the construction engineering construction site, such as channel material piled reinforced why mat wood, directly on the concrete floor (ground) on the surface is not?

- The steel placed timbers on or on the platform, it can be reinforced to prevent contact with moisture rust, but also can keep clean to prevent contamination of reinforced soil.

- Q:Can steel channels be used in theater and stage construction?

- Yes, steel channels can be used in theater and stage construction. Steel channels provide structural support and can be used for framing, rigging systems, and creating platforms and walkways. They are durable, versatile, and can withstand heavy loads, making them ideal for use in theater and stage construction.

- Q:How do steel channels contribute to the overall sustainability certifications of a project?

- Steel channels can contribute to the overall sustainability certifications of a project in several ways. Firstly, steel channels are often made from recycled steel, reducing the demand for new raw materials and minimizing the environmental impact of the production process. Additionally, steel channels have a long lifespan and are highly durable, which means they require less frequent replacement and maintenance, leading to reduced waste generation. Furthermore, steel channels can be easily recycled at the end of their life cycle, making them a sustainable choice. Overall, incorporating steel channels into a project can help achieve sustainability goals by reducing resource consumption, minimizing waste, and promoting circularity in the construction industry.

- Q:How do steel channels contribute to the overall versatility of a structure?

- A structure's overall versatility is enhanced in multiple ways by steel channels. First and foremost, the exceptional strength and durability of steel channels enable them to support heavy loads and withstand various environmental conditions. This grants designers and engineers the freedom to construct structures with greater flexibility and creativity. Furthermore, the wide range of sizes and shapes available in steel channels allows for precise customization to meet the specific requirements of a structure. The availability of various types of channels, such as C-channels, U-channels, and J-channels, empowers engineers to select the most suitable member for different applications. In addition, steel channels can be easily connected and combined with other steel components, including beams and columns, to create intricate and efficient structural systems. Their compatibility with other steel elements enhances the overall strength and stability of the structure, ensuring its longevity and safety. Moreover, steel channels can be fabricated and installed with relative ease, resulting in faster construction times and cost savings. The versatility of steel channels enables efficient construction methods, such as bolted connections or welding, which can be adjusted to meet project requirements and site conditions. Finally, steel channels are readily available and can be sourced from numerous suppliers, making them a cost-effective choice for construction projects. The abundance of steel channels in the market ensures easy access, facilitating their integration into a wide variety of structures. In conclusion, steel channels contribute to a structure's overall versatility through their strength, customization options, compatibility with other steel components, ease of fabrication and installation, and cost-effectiveness. These factors establish steel channels as an essential element in modern construction, enabling the creation of versatile and efficient structures.

- Q:Can steel channels be used for both residential and commercial construction?

- Steel channels are suitable for both residential and commercial construction. These versatile structural components can be utilized in a variety of ways, such as in the construction of building frames, support beams, and walls and ceilings. Due to their strength and stability, they are well-suited for both residential and commercial projects. Furthermore, steel channels offer durability, fire resistance, and a high load-bearing capacity, making them an excellent choice for construction projects of various sizes and types.

- Q:How do steel channels contribute to building adaptability?

- Steel channels contribute to building adaptability in several ways. Firstly, steel channels provide structural support and reinforcement to buildings. They are used in the construction of beams, columns, and trusses, which help distribute the weight of the building and ensure its stability. This structural strength allows for greater flexibility in building design and layout, as it enables the construction of larger open spaces and the use of fewer load-bearing walls. This adaptability is especially important in modern building design, where open floor plans and flexible spaces are highly valued. Secondly, steel channels are highly durable and resistant to various environmental factors. They can withstand extreme temperatures, high winds, and seismic activity, making them suitable for construction in diverse locations and climates. This durability is essential for building adaptability, as it ensures that the structure can withstand changes in environmental conditions and remain functional over time. Additionally, steel channels are easy to work with and can be easily modified or reconfigured. Their modular nature allows for easy assembly, disassembly, and modification of building components. This flexibility allows for future expansion or modification of the building without the need for major structural changes. It also enables the building to adapt to changing needs or functions, such as converting a space from a commercial office to a residential apartment. Furthermore, steel channels are highly recyclable, making them a sustainable choice for construction. They can be melted down and reused multiple times without losing their structural integrity. This recyclability contributes to building adaptability by allowing for the reuse of steel components in different construction projects, reducing waste, and conserving resources. In summary, steel channels contribute to building adaptability by providing structural support, durability, ease of modification, and recyclability. These qualities enable buildings to accommodate changing needs, layouts, and functions, making them versatile and adaptable over time.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Hot Rolled MS Mild JIS Steel U Channels for Strcutures

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 200000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords