Hot Rolled Mild Heavy Steel Rials for Minas GB, AREMA, DIN Standard

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 2000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications of Hot Rolled Mild Heavy Steel Rials for Minas GB, AREMA, DIN Standard

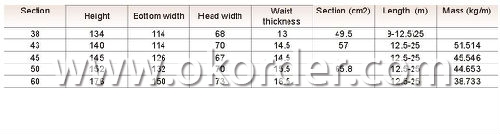

Sizes: 38kg, 43kg, 45kg, 50kg, 60kg

Production Standard: GB2585-81, AREMA, DIN, JIS, EN, etc.

Length: 6M-25M as the requriement of the client

Material: 50Mn, U71Mn, 900A, R260, etc.

Grade | Element(%) | ||||

C

| Mn | S

| P

| Si

| |

U71Mn

|

0.65—0.76 |

1.10—1.40 |

≤0.030 |

≤0.035

|

0.15-0.35

|

Invoicing on theoretical weight or actual weight as customer request

Payment terms: 30% advance payment by T/T, 70% payment against the copy of the B/L; 100% L/C at sight, etc.

Applications of Hot Rolled Mild Heavy Steel Rials for Minas GB, AREMA, DIN Standard

Heavy rail is suitable for the laying of main trunk line of the curves and the orbit of the tunnel can also be used for tower crane and other crane track. Be used for railway, subway, curve way, tunnel way, etc.

Packaging & Delivery of Hot Rolled Mild Heavy Steel Rials for Minas GB, AREMA, DIN Standard

1. Packing: it is nude packed in bundles by steel wire rod

2. Bundle weight: not more than 3.5MT for bulk vessel; less than 3 MT for container load

3. Marks:

Color marking: There will be color marking on both end of the bundle for the cargo delivered by bulk vessel. That makes it easily to distinguish at the destination port.

Tag mark: there will be tag mark tied up on the bundles. The information usually including supplier logo and name, product name, made in China, shipping marks and other information request by the customer.

If loading by container the marking is not needed, but we will prepare it as customer request.

4. Transportation: the goods are delivered by truck from mill to loading port, the maximum quantity can be loaded is around 40MTs by each truck. If the order quantity cannot reach the full truck loaded, the transportation cost per ton will be little higher than full load.

5. Delivered by container or bulk vessel

6. Delivery Time: All the Hot Rolled Steel Rail will be transpoted at the port of Tianjin, China within 30 days after receiving the advance payment by T/T or the orginal L/C at sight.

Inspection of Hot Rolled Mild Heavy Steel Rials for Minas GB, AREMA, DIN Standard

We will send the MTC of the factory to the clients dirrectly which contain the anlisis of the heat, chemiqul composition, phisical characteristicas, etc.

And our inspectors will arrive at the factory to meke the inspection of the size, length, weight and quantity before the transportation from the factory.

FAQ:

Q1: Why buy Hot Rolled Mild Heavy Steel Rials for Minas GB, AREMA, DIN Standard from OKorder.com?

A1: All products offered byOKorder.com are carefully selected from China's most reliable manufacturing enterprises. Through its ISO certifications, OKorder.com adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Q2: How do we guarantee the quality of Hot Rolled Mild Heavy Steel Rials for Minas GB, AREMA, DIN Standard?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

Q3: What is the normal tolerance of Hot Rolled Mild Steel Angle Beams for Structures and for Buildings?

A3: Normally 3%-5%, but we can also produce the goods according to the customers' request

- Q:How are steel rails protected against damage caused by landslides or slope instability?

- Steel rails are protected against damage caused by landslides or slope instability through various measures such as slope stabilization techniques, installation of retaining walls, and geotechnical monitoring systems. These methods help to prevent or mitigate the impact of landslides on railway tracks, ensuring the safety and functionality of the rail infrastructure.

- Q:How are steel rails protected against excessive vibrations?

- Several methods are utilized to protect steel rails against excessive vibrations. Resilient fastenings or rail pads are one of the primary approaches employed. These materials are placed between the rail and the fastening system to absorb and dissipate vibrations generated by passing trains. By acting as a cushion, resilient fastenings reduce the impact and vibrations transmitted to the rail. Another technique involves the use of ballast, a layer of crushed stones beneath the railway tracks. This ballast functions as a shock absorber, absorbing vibrations and evenly distributing the load of passing trains. Its presence aids in stabilizing the rails and minimizing excessive vibrations. In order to prevent excessive vibrations, regular maintenance and inspection of the rails are crucial. Any defects, such as cracks or damaged sections, are promptly identified and repaired. By ensuring the rails are well-maintained, the risk of vibrations is minimized. Furthermore, the design of the rail system itself plays a vital role in mitigating excessive vibrations. The alignment, curvature, and elevation of the tracks are carefully planned to reduce the occurrence and impact of vibrations. Employing proper track design techniques, such as providing transition curves, also helps in minimizing the vibrations caused by train movements. Ultimately, a combination of resilient fastenings, ballast, regular maintenance, and thoughtful rail system design work together to safeguard steel rails against excessive vibrations, ensuring the safe and efficient operation of railways.

- Q:How are steel rails protected against damage caused by animals?

- Steel rails are typically protected against damage caused by animals through various measures such as electrified fences, animal deterrent devices, and regular inspections to identify and repair any damage caused by animals.

- Q:What is the typical hardness of steel rails?

- The typical hardness of steel rails is around 200 to 300 Brinell hardness units (BHN).

- Q:What are the typical failure modes of steel rails?

- The typical failure modes of steel rails include fatigue cracking, rail wear, rail head deformation, and rail breakage.

- Q:How are steel rails protected against impact damage?

- Steel rails are protected against impact damage through the use of specialized materials and design techniques. One common method is the installation of shock-absorbing devices, such as rubber pads or resilient fasteners, which help absorb the impact energy and reduce the likelihood of damage. Additionally, proper maintenance practices, including regular inspections and repairs, are employed to identify and address any potential issues before they escalate into more significant damages.

- Q:What is the role of steel rails in track stability?

- The steel rails play a crucial role in ensuring track stability by providing a sturdy and durable foundation for trains to run on. They help distribute the weight of the train evenly across the track and guide the wheels along a fixed path, preventing excessive lateral movement. The strength and rigidity of steel rails also help absorb and distribute the dynamic forces exerted by passing trains, minimizing wear and tear on the track and ensuring a smooth and stable ride.

- Q:What are the safety measures for pedestrians near railway tracks with steel rails?

- There are several safety measures that pedestrians should adhere to when near railway tracks with steel rails to ensure their own well-being and prevent any accidents. These measures include: 1. Observe warning signs and signals: Pay attention to any warning signs, signals, or barriers that indicate the presence of a railway track. These signs are usually placed in advance to alert pedestrians of an upcoming railway crossing. 2. Cross at designated areas: Only cross railway tracks at designated pedestrian crossings. These areas are specifically designed for pedestrians to safely cross the tracks, and they often have barriers, gates, or flashing lights to ensure the safety of pedestrians. 3. Look and listen for approaching trains: Before crossing a railway track, make sure to look both ways and listen for any approaching trains. Trains can approach quickly and may not be easily noticeable, so it is important to stay vigilant and aware of your surroundings. 4. Avoid distractions: Avoid using electronic devices, listening to loud music, or engaging in any distracting activities when near railway tracks. Such distractions can prevent you from recognizing warning signs or hearing approaching trains. 5. Do not trespass on railway property: It is crucial to never trespass on railway property, as it is not only illegal but also extremely dangerous. Always use designated pedestrian crossings and avoid walking or loitering on or near the tracks. 6. Teach children about railway safety: Educate children about the potential dangers of railway tracks and the importance of following safety measures. Teach them to never play or walk on the tracks and to always use designated crossings. 7. Be aware of train schedules: If possible, familiarize yourself with train schedules in your area. Knowing the times when trains typically pass through can help you plan your activities and avoid crossing the tracks when trains are expected. 8. Stay clear of the tracks: Maintain a safe distance from the railway tracks, especially when a train is approaching or passing by. Trains can have a significant force and may have parts extending beyond the tracks, so it is crucial to stay clear to avoid any accidents. By following these safety measures, pedestrians can significantly reduce the risk of accidents and ensure their own safety when near railway tracks with steel rails. It is essential to always prioritize personal safety and be cautious when crossing or being in proximity to railway tracks.

- Q:What is quenched rail?

- Quenched rail is under speed quenching. It has on-line residual heat quenching and off-line heating quenching. The cooling mode is usually jet blast or jet wind and spray cooling, and its microstructure is pearlite. Hardness is HRC36~42.

- Q:Can steel rails be used in railway systems with limited maintenance access?

- Railway systems with limited maintenance access can make use of steel rails. These rails are extensively utilized worldwide in railway systems due to their ability to withstand wear and tear, their durability, and their strength. They offer a smooth and stable surface for trains to travel on while also being capable of bearing heavy loads. When it comes to railway systems with limited maintenance access, it is vital to select materials that necessitate minimal upkeep. Steel rails are renowned for their low maintenance requirements, making them well-suited for these types of environments. They possess a lengthy lifespan and can endure severe weather conditions and heavy traffic without compromising their structural integrity. Moreover, steel rails are relatively easy to inspect and repair. Specialized equipment can be employed to conduct routine inspections and identify any signs of wear, deformation, or damage. In the event that any issues are detected, repairs can be promptly carried out to ensure the safe and efficient operation of the railway system. To sum up, steel rails are indeed suitable for use in railway systems with limited maintenance access. Their durability, strength, and low maintenance requirements make them an excellent choice for such environments. By conducting proper inspections and timely repairs, steel rails can serve as a dependable and long-lasting infrastructure for the railway system.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Hot Rolled Mild Heavy Steel Rials for Minas GB, AREMA, DIN Standard

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 2000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords