Hot Rolled Mild Heavy Steel Rials for Minas 50Mn, U71Mn Made in China

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 2000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications of Hot Rolled Mild Heavy Steel Rials for Minas 50Mn, U71Mn Made in China

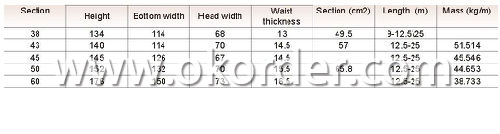

Sizes: 38kg, 43kg, 45kg, 50kg, 60kg.

Production Standard: GB2585-81, DIN, AREMA, JIS, BS, UIC, etc.

Material: 50MN, U71MN, 900A, 110A, etc.

Length: 6m-25m according to the requriements of the clients

Invoicing on theoretical weight or actual weight as customer request

Payment terms: 30% advance payment by T/T, 70% payment against the copy of the B/L; 100% L/C at sight, etc.

Applications of Hot Rolled Mild Heavy Steel Rials for Minas 50Mn, U71Mn Made in China

Heavy rail is suitable for the laying of main trunk line of the curves and the orbit of the tunnel can also be used for tower crane and other crane track.

Tunnel way, curve way, railway, subway, transportation track, express, etc.

Package & Delivery of Hot Rolled Mild Heavy Steel Rials for Minas 50Mn, U71Mn Made in China

1. Package: it is nude packed in bundles by steel wire rod

2. Bundle weight: not more than 3.5MT for bulk vessel; less than 3 MT for container load

3. Marks:

Color marking: There will be color marking on both end of the bundle for the cargo delivered by bulk vessel. That makes it easily to distinguish at the destination port.

Tag mark: there will be tag mark tied up on the bundles. The information usually including supplier logo and name, product name, size, length, grade, made in China, shipping marks and other information request by the customer.

If loading by container the marking is not needed, but we will prepare it as customer request.

4. Transportation: the goods are delivered by truck from mill to loading port, the maximum quantity can be loaded is around 40MTs by each truck. If the order quantity cannot reach the full truck loaded, the transportation cost per ton will be little higher than full load.

5. Delivered by container or bulk vessel

6. Delivery Time: All the Hot Rolled Steel Rail will be transpoted at the port of Tianjin, China within 30 days after receiving the advance payment by T/T or the orginal L/C at sight.

Inspection of Hot Rolled Mild Heavy Steel Rials for Minas 50Mn, U71Mn Made in China

We will send the MTC of the factory to the clients dirrectly which contain the anlisis of the heat, chemiqul composition, phisical characteristicas, etc.

And our inspectors will arrive at the factory to meke the inspection of the size, length, weight and quantity before the transportation from the factory.

FAQ

Q1: Why buy Hot Rolled Mild Heavy Steel Rials for Minas 50Mn, U71Mn Made in Chinafrom OKorder.com?

A1: All products offered byOKorder.com are carefully selected from China's most reliable manufacturing enterprises. Through its ISO certifications, OKorder.com adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

Q3: How soon can we receive the product after purchase Hot Rolled Mild Heavy Steel Rials for Minas 50Mn, U71Mn Made in China?

A3: Within three days of placing an order, we will begin production. The specific shipping date is dependent upon international and government factors, but is typically 20 to 30 workdays.

- Q:Can steel rails be used in areas with high temperatures?

- Yes, steel rails can be used in areas with high temperatures. Steel is known for its high strength and resistance to heat, making it a suitable material for railway tracks even in hot environments.

- Q:What are the safety measures taken during steel rail construction?

- During steel rail construction, several safety measures are taken to ensure the protection of workers and the general public. These include implementing proper training programs for workers, providing them with personal protective equipment such as helmets, safety glasses, and gloves, conducting regular safety inspections of equipment and machinery, ensuring proper signage and barriers are in place to warn and redirect traffic, and adhering to strict protocols for handling, transporting, and installing steel rails. Additionally, safety protocols are followed to prevent accidents, such as proper communication between workers, regular maintenance of tools and equipment, and implementing emergency response plans in case of unforeseen incidents.

- Q:What is the impact of heavy axle loads on steel rails?

- The impact of heavy axle loads on steel rails can have both positive and negative effects. One of the main positive impacts is that heavy axle loads can increase the efficiency and capacity of rail transportation. By allowing trains to carry more weight per axle, heavy axle loads enable the transportation of larger quantities of goods in a single trip. This can help to reduce transportation costs, improve productivity, and contribute to economic growth. Additionally, heavy axle loads can enhance the competitiveness of rail transportation compared to other modes, such as road or air, particularly for heavy or bulk commodities. However, heavy axle loads can also exert significant strain on steel rails, leading to various negative impacts. The increased weight can accelerate rail wear and fatigue, causing the rails to deform, crack, or even break. This can result in track maintenance issues, such as the need for more frequent rail replacements, repairs, and inspections. Moreover, the degradation of steel rails due to heavy axle loads can lead to a decrease in the overall safety and reliability of the rail network. To mitigate the negative impacts of heavy axle loads, proper engineering and maintenance practices are essential. This includes the use of high-quality steel rails that can withstand heavier loads, as well as implementing effective monitoring and inspection systems to identify potential rail defects early on. Additionally, regular maintenance and timely repairs are crucial to ensure the integrity and longevity of the rail infrastructure. Overall, while heavy axle loads offer advantages in terms of increased transportation capacity and efficiency, it is important to carefully manage and address the resulting challenges to ensure the long-term sustainability and safety of rail networks.

- Q:How do steel rails contribute to train stability?

- Steel rails contribute to train stability in multiple ways. Firstly, their sturdy construction ensures that the train tracks remain straight and aligned, preventing any lateral movement that could cause the train to derail. Secondly, the smooth and polished surface of steel rails reduces friction between the train wheels and the tracks, allowing for efficient movement and minimizing the risk of skidding or sliding. Additionally, the consistent gauge and uniformity of steel rails ensure that the train wheels are properly guided, maintaining balance and stability throughout the journey. Consequently, steel rails play a vital role in keeping trains on track, ensuring safe and stable transportation.

- Q:Can steel rails be used in areas with seismic activity?

- Indeed, areas with seismic activity can accommodate the usage of steel rails. Steel possesses renowned strength and resilience, rendering it an optimal choice for constructing railroad tracks. When adequately designed and installed, steel rails can endure the vibrations and ground shifts induced by seismic activity. Moreover, engineers frequently combine steel rails with other engineering methodologies, including reinforced foundations and flexible rail fastening systems, to bolster their capacity to withstand seismic incidents. These precautions guarantee the security and steadfastness of railway infrastructure in regions susceptible to earthquakes and other seismic occurrences.

- Q:How do steel rails contribute to reducing the risk of rail squats and shelling?

- Steel rails contribute to reducing the risk of rail squats and shelling by providing a strong and durable track structure. The high tensile strength of steel helps to withstand the heavy loads and dynamic forces exerted by trains, minimizing the chances of rail deformation. Additionally, steel rails offer excellent resistance to wear and fatigue, ensuring longevity and reducing the likelihood of cracks or fractures. This overall robustness of steel rails helps to maintain track stability, preventing the formation of rail squats and shelling, which can lead to derailments and other safety hazards on the railway.

- Q:Can steel rails be used in railway systems with sharp curves?

- Yes, steel rails can be used in railway systems with sharp curves. However, the design and installation of these rails need to consider factors such as the radius of the curve, the speed of the trains, and the weight of the rolling stock. Specialized techniques and technologies, such as bending the rails to match the curve or using flange lubrication, are often employed to ensure safe and efficient operation on curved tracks.

- Q:What are the safety measures for workers during steel rail repairs?

- During steel rail repairs, workers should follow several safety measures to minimize the risk of accidents and ensure their well-being. These measures include wearing appropriate personal protective equipment (PPE) such as hard hats, safety glasses, high-visibility clothing, steel-toed boots, and gloves. Workers should also be trained on proper techniques for manual handling and lifting heavy objects, as well as how to safely operate any machinery or tools involved in the repair process. Additionally, the work area should be well-lit, and proper signage should be in place to warn others of potential hazards. Regular inspections of equipment and tools should be conducted, and workers should be encouraged to report any safety concerns or incidents immediately. Overall, adhering to these safety measures can help protect workers during steel rail repairs and prevent injuries.

- Q:What is the role of steel rails in ensuring train stability?

- Steel rails play a crucial role in ensuring train stability as they provide a solid foundation for the train to travel on. The weight of the train is distributed evenly across the steel rails, which helps to maintain balance and prevent the train from derailing. One of the main functions of steel rails is to guide the train and keep it on track. The rails are designed to have a specific shape, with a flange on the inside of the railhead, which fits into the groove of the train's wheels. This flanged wheel-rail interaction helps to keep the train aligned and prevents it from deviating off the track. Furthermore, steel rails provide a smooth and continuous surface for the train to move on. This reduces the friction between the train's wheels and the rails, allowing the train to travel at high speeds with minimal resistance. This smooth surface also helps to minimize vibrations and bumps, providing a comfortable ride for passengers. In addition to stability, steel rails also contribute to the overall safety of train operations. They are designed to withstand heavy loads and provide resistance against wear and tear. Regular maintenance and inspection of the rails ensure that any defects or damages are promptly identified and repaired, preventing accidents and ensuring the safe passage of trains. Overall, steel rails are essential for train stability as they guide the train, distribute its weight, reduce friction, and provide a safe and smooth surface for the train to travel on. Without steel rails, trains would struggle to maintain stability and safety, making them an indispensable component of railway infrastructure.

- Q:Can steel rails be used for elevated railway tracks?

- Yes, steel rails can be used for elevated railway tracks. Steel rails are commonly used for both ground-level and elevated railway tracks due to their durability, strength, and ability to withstand heavy loads.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Hot Rolled Mild Heavy Steel Rials for Minas 50Mn, U71Mn Made in China

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 2000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords