Hot Rolled H13 Standard Steel Bar Sizes

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 30 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

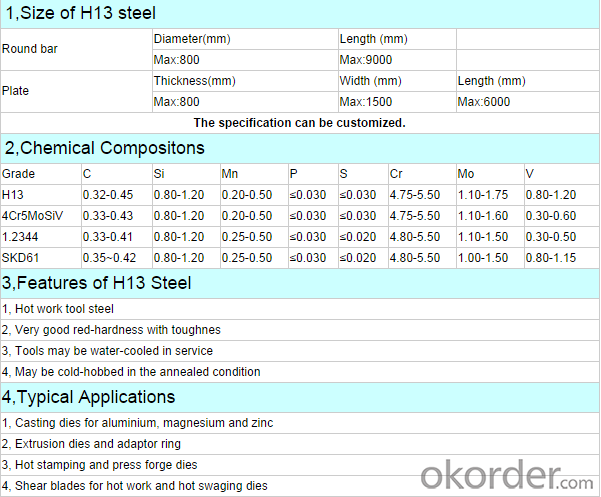

Hot Rolled H13 Standard Steel Bar Sizes

Product information:

Specifications

Songshun Hot Rolled H13 Standard Steel Bar Sizes

1.A/N/Q+T

2.Sample free

3.Black or Bright

4.Dia Max:800mm

Product show

Workshop show

Our service:

-High manufacturing accuracy

-High strength

-Small inertia resistance

-Strong heat dissipation ability

-Good visual effect

-Reasonable price

Chose happens because of quality, then price, We can give you both.Additionally, we can also offer professional products inquiry, products knowledge train(for agents), smooth goods delivery, exellent customer solution proposals.Our service formula: good quality+good price+good service=customer's trust

SGS test is available, customer inspection before shipping is welcome, third party inspection is no problem.

If you need the sample, please feel free to let me know. Any question, we will contact you ASAP!

- Q:Can special steel be used in construction?

- Yes, special steel can be used in construction. Special steel, also known as alloy steel, offers superior strength, durability, and resistance to corrosion and wear compared to regular steel. It is commonly used in the construction of high-rise buildings, bridges, and other structures that require exceptional strength and longevity. Additionally, special steel can be customized to meet specific project requirements, making it a versatile choice for construction applications.

- Q:What are the challenges in welding special steel?

- One of the main challenges in welding special steel is its high carbon content, which can result in increased hardness and brittleness. This requires careful control of the welding process, including preheating and post-weld heat treatment, to prevent cracking and ensure proper weld strength. Additionally, special steels often have alloying elements that can influence the weldability, such as chromium, nickel, or molybdenum, requiring specific filler materials and welding techniques. Overall, the challenges in welding special steel lie in achieving a strong and defect-free weld while maintaining the desired mechanical properties of the steel.

- Q:How is precipitation-hardening steel used in the aerospace industry?

- Precipitation-hardening steel, also known as PH steel, is extensively used in the aerospace industry due to its exceptional strength-to-weight ratio and excellent corrosion resistance. This type of steel undergoes a heat treatment process that enables the formation of fine precipitates within its structure, resulting in improved mechanical properties. In aerospace applications, precipitation-hardening steel is commonly utilized for manufacturing critical components such as landing gear, engine parts, and structural elements. Its high strength and durability allow for the construction of lighter and more fuel-efficient aircraft, enhancing overall performance and safety in the aerospace sector.

- Q:How does special steel contribute to reducing product costs while maintaining quality?

- Special steel contributes to reducing product costs while maintaining quality through several ways. Firstly, special steel possesses enhanced strength and durability, allowing manufacturers to produce products with thinner gauges or smaller dimensions, reducing material usage and overall costs. Additionally, its superior corrosion resistance and longevity ensure that the products have a longer lifespan, reducing the need for frequent replacements. Moreover, special steel's exceptional machinability enables efficient production processes, reducing labor costs and increasing productivity. Lastly, its high precision and consistency in manufacturing contribute to minimizing defects and waste, resulting in cost savings and improved product quality. Overall, special steel's unique properties and characteristics enable manufacturers to optimize production, thereby reducing costs without compromising on product quality.

- Q:What are the applications of tool steel?

- Tool steel is widely used in various applications due to its exceptional hardness, wear resistance, and ability to retain sharp edges. It is commonly utilized in the manufacturing of cutting tools such as drills, saw blades, and milling cutters. Additionally, tool steel finds applications in the production of molds for plastic injection or die casting, as well as in the manufacturing of punches, dies, and shears used in metalworking processes. Its high strength and heat resistance also make it suitable for applications in the aerospace and automotive industries, where it is utilized in components like engine valves, gears, and shafts.

- Q:How does heat treatment affect the properties of special steel?

- Heat treatment can significantly impact the properties of special steel. The process involves heating and cooling the steel in a controlled manner, which alters its microstructure, resulting in changes to its hardness, strength, toughness, and ductility. By carefully selecting the temperature and duration of heat treatment, desired properties such as improved hardness, increased strength, and enhanced wear resistance can be achieved. Additionally, heat treatment can also relieve internal stresses, enhance machinability, and improve dimensional stability of special steel.

- Q:How does special steel contribute to the industrial machinery aftermarket industry?

- By providing high-quality and durable components, special steel plays a vital role in the industrial machinery aftermarket industry. It enhances machinery performance and longevity, which is crucial in this industry. One of the main advantages of special steel is its exceptional strength and resistance to wear and tear. Regular steel components deteriorate quickly due to heavy loads, extreme temperatures, and corrosive environments. However, special steel alloys are specifically designed to withstand these harsh conditions. This ensures that machinery operates efficiently for a longer period. In addition, special steel offers excellent machinability, making it easier to manufacture intricate and precise components. This enables aftermarket manufacturers to produce replacement parts that fit perfectly into existing machinery. As a result, downtime during repairs and maintenance is minimized. Special steel's machinability also allows for customization, as it can be easily shaped and modified according to the specific requirements of different machinery models. Moreover, special steel's exceptional heat resistance makes it ideal for producing high-temperature components used in industrial machinery. These components need to withstand intense heat without losing their structural integrity. Special steel alloys possess excellent heat resistance properties, ensuring that machinery can operate at high temperatures without compromising performance or safety. Furthermore, special steel contributes to the industrial machinery aftermarket industry by providing corrosion-resistant components. Machinery in industries such as oil and gas or marine is often exposed to corrosive substances or environments. Regular steel components are susceptible to corrosion, leading to premature failure and expensive repairs. However, special steel alloys are highly resistant to corrosion, enhancing the durability and reliability of machinery in these demanding conditions. Overall, special steel's unique properties, including strength, machinability, heat resistance, and corrosion resistance, significantly contribute to the industrial machinery aftermarket industry. By utilizing special steel components, manufacturers can enhance machinery performance, durability, and longevity, reducing downtime, and improving overall operational efficiency.

- Q:What are the properties of die steel?

- Die steel is a type of tool steel that possesses a number of important properties. It has excellent wear resistance, high hardness, and good toughness, making it ideal for use in applications that involve cutting, shaping, or forming materials. Die steel also exhibits good heat resistance, enabling it to retain its hardness and strength even at elevated temperatures. Additionally, it has good machinability, enabling it to be easily shaped and formed into various die components. Overall, die steel is known for its durability, strength, and ability to withstand high-stress environments.

- Q:What are the different methods for annealing special steel?

- There are several methods for annealing special steel, including full annealing, process annealing, stress relief annealing, and spheroidizing annealing. Full annealing involves heating the steel to a temperature above the critical range and then slowly cooling it to room temperature. Process annealing is used to improve machinability and involves heating the steel to a temperature below the critical range and then cooling it in still air. Stress relief annealing is carried out to reduce internal stresses in the steel by heating it to a temperature below the critical range and then cooling it slowly. Spheroidizing annealing is used to improve the steel's formability and involves heating it to a temperature below the critical range and then cooling it slowly. Each method has its own specific purpose and benefits for annealing special steel.

- Q:What are the different mining grades of special steel?

- Special steel is a term used to describe steel alloys that are specially designed for applications that require exceptional strength, durability, corrosion resistance, or other unique properties. The mining industry heavily relies on special steel for various components, tools, and equipment used in mining operations. There are several types of special steel grades specifically tailored for mining purposes, each possessing its own distinct properties and characteristics. These grades are typically classified based on their chemical composition, mechanical properties, and intended use in mining applications. Some common examples of special steel grades used in mining are: 1. High-strength Low Alloy (HSLA) Steel: HSLA steel is renowned for its remarkable strength and toughness, making it perfect for heavy-duty mining machinery and equipment. It offers exceptional weldability and corrosion resistance, which is crucial in harsh mining environments. 2. Stainless Steel: Stainless steel is extensively utilized in mining due to its superb resistance to corrosion and ability to withstand high temperatures. It is commonly employed in mining equipment such as pipes, fittings, and tanks, where resistance to corrosion and abrasion is of utmost importance. 3. Tool Steel: Tool steel is specifically engineered for cutting, drilling, and shaping tools used in mining operations. It possesses high hardness, wear resistance, and toughness, making it suitable for demanding applications like drilling bits, hammers, and cutting tools. 4. Wear-resistant Steel: Wear-resistant steel is specially designed to withstand abrasive conditions and minimize wear and tear in mining equipment. It is commonly employed in mining buckets, conveyor belts, and crushers to extend their service life and reduce maintenance. 5. Heat-resistant Steel: Heat-resistant steel is essential for mining applications involving high temperatures, such as smelting and refining processes. It retains its strength and structural integrity even at elevated temperatures, reducing the risk of equipment failure and ensuring operational efficiency. 6. Corrosion-resistant Steel: Corrosion-resistant steel finds extensive use in mining operations where exposure to corrosive substances like acids or seawater is common. It prevents rusting and degradation, thereby prolonging the lifespan of mining equipment and structures. It is important to note that the specific special steel grades used in mining may vary depending on the manufacturer and the intended use. To ensure optimal performance and suitability for mining applications, it is advisable to consult with steel manufacturers or industry experts who can provide guidance on selecting the appropriate grade for specific mining requirements.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Hot Rolled H13 Standard Steel Bar Sizes

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 30 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords