Hot Rolled Flat Steel Bars SS400

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

OKorder is offering Flat Steel Bars SS400 at great prices with worldwide shipping. Our supplier is a world-class manufacturer of steel, with our products utilized the world over. OKorder annually supplies products to European, North American and Asian markets. We provide quotations within 24 hours of receiving an inquiry and guarantee competitive prices.

Product Applications:

Flat Steel Bars SS400 are ideal for structural applications and are widely used in the construction of buildings and bridges, and the manufacturing, petrochemical, and transportation industries.

Product Advantages:

OKorder's Flat Steel Bars SS400 are durable, strong, and resist corrosion.

Main Product Features:

· Premium quality

· Prompt delivery & seaworthy packing (30 days after receiving deposit)

· Corrosion resistance

· Can be recycled and reused

· Mill test certification

· Professional Service

· Competitive pricing

Product Specifications:

Manufacture: Hot rolled

Grade: SS400

Certificates: ISO, SGS, BV, CIQ

Length: 6m – 12m, as per customer request

Origin place: China

Thickness: 3mm-30mm

Width:20mm-200mm

Length: Max 12m

Certification: SGS/BV

Chemical composition of Q235

Alloy No | Grade | Element(%) | ||||

C

| Mn

| S

| P

| Si

| ||

Q235

|

B

|

0.12—0.20 |

0.3—0.7 |

≤0.045 |

≤0.045

|

≤0.3

|

Physical properties of Q235

Alloy No | Grade | Yielding strength point(Mpa) | Tensile strength (Mpa) | Elongation after fracture(%) | ||||||

Thickness (mm) | Thickness (mm) | |||||||||

≤16 | >16--40 | >40--60 | >60--100 | ≤16 | >16--40 | >40--60 | >60--100 | |||

≥ | ≥ | |||||||||

Q235 |

B |

235 |

225 |

215 |

205 |

375--500 |

26 |

25 |

24 |

23 |

FAQ:

Q1: Why buy Materials & Equipment from OKorder.com?

A1: All products offered byOKorder.com are carefully selected from China's most reliable manufacturing enterprises. Through its ISO certifications, OKorder.com adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

Q3: What’s the Processes Flow of Flat Steel Bars?

A3:The steel flat bar is made through three processes:

1.Feeding the material: Feeding the row material (the steel plate) to Slitting Line.

2.Slitting:The steel plate would be slitted into expected width by lengthways cutter.

3. Leveled and cutting: The plat bar would be ground into level by the grinder and then cut into required length.

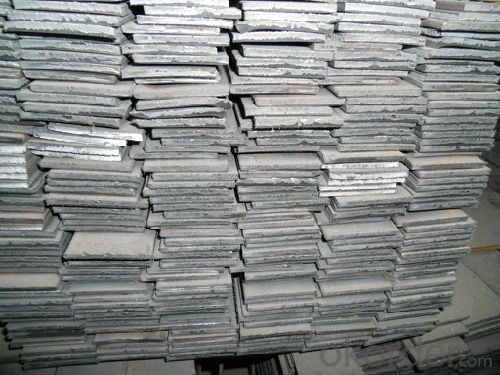

Images:

- Q:Are steel flat bars resistant to impact or shock?

- Yes, steel flat bars are generally resistant to impact or shock due to their high tensile strength and durability. They are commonly used in applications where resistance to impact or shock is required, such as construction, manufacturing, and structural projects.

- Q:Are steel flat bars commonly used in the oil and gas industry?

- Steel flat bars are frequently employed in the oil and gas sector. These flat bars find extensive application in the construction of structures, platforms, and equipment utilized in oil and gas exploration, production, and refining procedures. The exceptional strength and endurance of steel make it a perfect selection for enduring the industry's rigorous conditions and demanding prerequisites. Furthermore, steel flat bars can be effortlessly fabricated and welded, enabling efficient customization and assembly of equipment and structures. In summary, steel flat bars are a vital element in the oil and gas industry, serving a pivotal role in guaranteeing the safety, dependability, and effectiveness of operations.

- Q:What are the different surface finishes for stainless steel flat bars?

- There are several different surface finishes available for stainless steel flat bars, depending on the specific requirements and desired aesthetic appearance. Some of the most common surface finishes include: 1. Mill Finish: This is the most basic and standard finish for stainless steel flat bars. It is achieved by passing the steel through a set of rollers to achieve a smooth and uniform surface. Mill finish has a matte appearance and is typically used for industrial applications where appearance is not a major concern. 2. Brushed Finish: Also known as satin finish, this surface finish is achieved by using abrasive material to create a pattern of fine parallel lines on the surface of the stainless steel. Brushed finish has a dull, matte appearance and provides a slightly textured feel. It is commonly used for decorative purposes in architectural and interior design applications. 3. Mirror Finish: Mirror finish is achieved by polishing the stainless steel surface to a highly reflective, mirror-like appearance. This finish is achieved using progressively finer abrasives until the desired level of reflectivity is achieved. Mirror finish is often used in decorative applications where a sleek and glossy appearance is desired, such as in furniture, appliances, and automotive components. 4. Bead Blast Finish: Bead blasting involves propelling small spherical particles against the stainless steel surface to create a uniform, textured finish. This finish has a matte appearance with a slightly rough feel and is commonly used for architectural and decorative applications, as it provides a unique and distinctive look. 5. Etched Finish: Etching is a process where the stainless steel surface is chemically treated to create a pattern or design. This finish can range from subtle and delicate to bold and intricate, depending on the desired effect. Etched finish is often used in decorative applications, such as signage, artwork, and jewelry. These are just a few examples of the different surface finishes available for stainless steel flat bars. Each finish offers its own unique characteristics and can be chosen based on the desired appearance, functionality, and application requirements.

- Q:Are steel flat bars available in standard lengths or custom lengths?

- Steel flat bars are available in both standard lengths and custom lengths.

- Q:What are the different methods of surface cleaning for steel flat bars?

- There are several methods that can be used for surface cleaning of steel flat bars. The choice of method depends on the level of cleaning required and the condition of the bars. Some common methods include: 1. Mechanical cleaning: This method involves using mechanical tools such as wire brushes, abrasive pads, or sandpaper to remove dirt, rust, or other contaminants from the surface of the steel flat bars. It is a manual process that requires physical effort and can be time-consuming. 2. Chemical cleaning: Chemical cleaners or solvents can be used to dissolve or remove stubborn stains, grease, or oil from the surface of steel flat bars. The choice of cleaner depends on the type of contaminants to be removed. It is important to follow safety guidelines and use appropriate protective equipment when using chemical cleaners. 3. Power washing: Power washing or pressure washing is a method that uses high-pressure water jets to clean the surface of steel flat bars. This method is effective in removing loose debris, dirt, and grime. It is commonly used for outdoor or larger surfaces where manual cleaning may not be practical. 4. Sandblasting: Sandblasting is a technique that involves using high-pressure air or water along with abrasive particles to remove rust, paint, or other coatings from the surface of steel flat bars. It is a highly efficient method but requires specialized equipment and trained personnel to ensure safe and effective cleaning. 5. Electrochemical cleaning: This method utilizes an electrochemical process to remove rust or other oxidation from the surface of steel flat bars. It involves immersing the bars in an electrolyte solution and applying an electric current to trigger a chemical reaction that dissolves the contaminants. This method is commonly used for larger surfaces or when dealing with heavily corroded steel. It is important to note that the choice of cleaning method should be based on the specific requirements of the steel flat bars and the desired level of cleanliness. It is recommended to consult with professionals or manufacturers to determine the most suitable method for surface cleaning in each particular case.

- Q:What are the different grades of steel used for flat bars?

- There are several grades of steel used for flat bars, including low carbon steel (1018, A36), medium carbon steel (1045), high carbon steel (1095), alloy steel (4140), and stainless steel (304, 316). The choice of grade depends on the specific application and desired properties such as strength, durability, and corrosion resistance.

- Q:What are the different surface treatments available for steel flat bars to enhance aesthetics?

- There are several surface treatments available for steel flat bars to enhance aesthetics. Some common options include polishing, brushing, sandblasting, or applying a decorative finish such as powder coating or plating. These treatments can improve the appearance of the steel flat bars and make them more appealing for various applications.

- Q:How do steel flat bars perform in high-pressure environments?

- Steel flat bars are known for their excellent strength and durability, making them suitable for high-pressure environments. The flat shape of these bars allows them to distribute pressure evenly, minimizing the risk of deformation or failure under extreme conditions. In high-pressure environments, steel flat bars exhibit remarkable resistance to bending and breaking, ensuring the structural integrity of various applications. Their high tensile strength enables them to withstand significant pressure without compromising their performance. Additionally, the hardness of steel bars helps them resist wear and abrasion, making them ideal for environments where high pressures are coupled with harsh conditions. Steel flat bars also possess good corrosion resistance, which is crucial in high-pressure environments where exposure to moisture or corrosive substances is common. They can be further enhanced through protective coatings or treatments to provide even greater resistance against corrosion. Moreover, steel flat bars have excellent weldability, allowing for easy fabrication and customization to suit specific high-pressure applications. This flexibility enables engineers and designers to utilize steel flat bars in various industries, such as construction, manufacturing, and oil and gas. However, it is important to consider the specific requirements and properties of the steel flat bars used in high-pressure environments. Factors such as the grade of steel, dimensions, and manufacturing process can influence their performance. Consulting with a materials expert or referring to industry standards and guidelines can help ensure the appropriate selection and utilization of steel flat bars in high-pressure applications.

- Q:Can steel flat bars be used in the manufacturing of automotive parts?

- Yes, steel flat bars can be used in the manufacturing of automotive parts. Steel flat bars offer high strength and durability, making them suitable for various automotive applications such as chassis components, brackets, supports, and structural reinforcements. Their versatility, cost-effectiveness, and ability to be easily fabricated and welded make them a popular choice in the automotive industry.

- Q:Can steel flat bars be used for making frames or supports for signage?

- Indeed, frames or supports for signage can be fashioned from steel flat bars. These steel flat bars are renowned for their robustness and sturdiness, rendering them apt for offering structural reinforcement to signage. By skillfully shaping and welding them, custom frames can effortlessly be crafted to securely hold and exhibit signage. Moreover, steel flat bars possess resistance against corrosion, thereby rendering them perfect for outdoor signage ventures that may encounter diverse weather conditions. In summary, steel flat bars emerge as a dependable preference for constructing frames or supports for signage due to their strength, durability, and corrosion-resistant properties.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Hot Rolled Flat Steel Bars SS400

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords