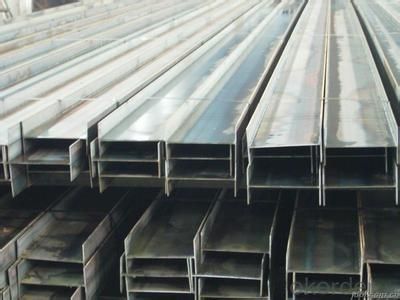

Hot Rolled Constructional U Beam Steel Channel Steel

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 4000 PCS

- Supply Capability:

- 40000 PCS/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

Hot Rolled Constructional U Beam Steel Channel Steel Details

Standard: | ASTM,GB,JIS | Dimensions: | 75*40-150*75mm | Grade: | q235 |

Place of Origin: | Hebei China (Mainland) | Brand Name: | Huikun | Material | S400 A36,Q235 |

Shape: | U Channel | Application: | bridge,construction ,buildings | Perforated Or Not: | Not Perforated |

Packaging & Delivery

Packaging Detail: | seaworthy export packing |

Delivery Detail: | 30days after getting l/c or t/t advance |

Hot Rolled Constructional U Beam Steel Channel Steel Specifications

Material :S400 A36,Q235

Size: 75*40mm-150*75 mm

Application: construction,bridge,building

Hot Rolled Constructional U Beam Steel Channel Steel Pictures

- Q:What are the load-bearing capabilities of steel channels?

- Steel channels have high load-bearing capabilities due to their structural design and material strength. The load-bearing capacity of steel channels depends on various factors such as the size, shape, and thickness of the channel, as well as the type of steel used. However, in general, steel channels are known for their ability to support heavy loads and are commonly used in construction and engineering projects where strength and durability are crucial.

- Q:How do steel channels contribute to fire resistance in buildings?

- There are several ways in which steel channels contribute to fire resistance in buildings. To begin with, steel channels are commonly utilized as structural components in building construction. They serve as beams, columns, or joists, offering support and stability to the overall structure. In the event of a fire, these steel channels play a crucial role in maintaining the building's integrity. Steel has a high melting point and retains its strength at high temperatures, thus preventing the building from collapsing during a fire. This structural stability allows occupants to evacuate safely and provides firefighters with a safer environment to combat the fire. Additionally, steel channels can serve as fire barriers or fireproofing materials. They can be installed to enclose or protect vulnerable areas like electrical conduits, pipes, or ventilation systems, which are prone to heat transfer and can contribute to the spread of fire. By enclosing these elements with steel channels, the risk of fire propagation is minimized. Steel channels can also be utilized to create fire-resistant compartments or fire-rated walls, restricting the spread of fire to specific areas and enabling occupants to evacuate safely. Furthermore, steel channels can be combined with other fire-resistant materials to enhance their effectiveness. For example, they can be filled with fire-resistant insulation materials such as mineral wool or vermiculite, providing additional thermal protection. This insulation helps reduce heat transfer and delays the temperature rise on the unexposed side of the steel channel, thus increasing the fire resistance of the building. In conclusion, steel channels play a crucial role in ensuring fire resistance in buildings. Their structural integrity and ability to withstand high temperatures prevent building collapse during fires, allowing occupants valuable time to evacuate. Moreover, steel channels can function as fire barriers, enclosing vulnerable elements and limiting the spread of fire. By combining steel channels with fire-resistant insulation, their fire resistance effectiveness is further enhanced, making them an essential component in building design and construction.

- Q:What is the purpose of steel channels?

- Steel channels have a variety of purposes across different industries and construction projects. Their primary function is to provide structural support and increase the stability of a structure. They are frequently utilized in the construction of buildings, bridges, and infrastructure projects. The design of steel channels allows for the distribution of weight and load in a structure, ensuring its ability to withstand external forces. They are commonly used as beams or columns, adding strength and rigidity to the overall framework. Additionally, steel channels can serve as bracing elements, preventing lateral movements and improving the stability of a structure. Another purpose of steel channels is to facilitate the installation of essential utilities such as electrical wiring, plumbing, and HVAC systems. Channels can be incorporated into walls or ceilings, enabling the concealed installation of these utilities. This not only provides a tidy and organized appearance but also ensures the safety and longevity of the building's infrastructure. Furthermore, steel channels are widely employed in the manufacturing and industrial sectors. They can be utilized to create conveyor systems, support equipment, and machinery. The durability and strength of steel channels make them well-suited for handling heavy loads and withstanding harsh working environments. In conclusion, steel channels offer structural support, enhance stability, and aid in the installation of utilities and equipment. Their versatility, strength, and durability make them a preferred choice for a wide range of construction and industrial applications.

- Q:What are the different cutting techniques for steel channels?

- There are several cutting techniques for steel channels, including manual cutting with a hacksaw or a cutting torch, mechanical cutting with a bandsaw or a circular saw, and CNC plasma cutting. Each technique has its advantages and is selected based on factors such as the thickness and shape of the steel channel, precision requirements, and production volume.

- Q:Are steel channels customizable in terms of size and shape?

- Yes, steel channels can be customized in terms of size and shape to meet specific project requirements.

- Q:What is the maximum length of steel channels available?

- The maximum length of steel channels may differ based on the manufacturer and the specific type of steel channel. Typically, steel channels come in standard lengths that range from 20 feet (6.1 meters) to 40 feet (12.2 meters). While certain manufacturers may provide customized lengths that exceed these standard sizes, it is crucial to acknowledge that longer lengths might necessitate special handling and transportation arrangements.

- Q:Do steel channels have any specific electrical conductivity properties?

- No, steel channels do not have specific electrical conductivity properties. Steel is generally considered to be a poor conductor of electricity compared to other metals like copper or aluminum. This is because steel is a ferrous metal, meaning it contains iron, which has a relatively high resistance to the flow of electrical current. Therefore, steel channels are not commonly used for electrical applications where high electrical conductivity is required.

- Q:Can steel channels be used for supporting solar panels?

- Indeed, steel channels have the capability to support solar panels. These channels are frequently employed in construction due to their robustness and resilience, rendering them well-suited for bearing the weight of solar panels. They furnish a sturdy and dependable framework for securing the panels in position, guaranteeing their correct installation and operation. Steel channels can be effortlessly tailored and modified to accommodate the precise demands of the solar panel installation, thus rendering them a flexible option for supporting solar panels. Moreover, steel channels provide protection against adverse weather conditions, ensuring the enduring stability and security of the solar panel system.

- Q:Are steel channels suitable for the power generation manufacturing industry?

- Yes, steel channels are suitable for the power generation manufacturing industry. Steel channels offer excellent strength and durability, making them ideal for supporting heavy equipment and structures in power plants. They can be customized to meet specific requirements and are resistant to corrosion, which is crucial in power generation facilities where exposure to moisture and chemicals is common. Additionally, steel channels have excellent thermal conductivity, ensuring efficient heat transfer in power generation processes.

- Q:Can steel channels be used for creating support structures for HVAC systems?

- Yes, steel channels can be used for creating support structures for HVAC systems. Steel channels provide strength, stability, and durability required to support the weight and vibrations of HVAC components such as ductwork, pipes, and units. Their design flexibility and ability to withstand heavy loads make them a suitable choice for constructing reliable and long-lasting support structures for HVAC systems.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Hot Rolled Constructional U Beam Steel Channel Steel

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 4000 PCS

- Supply Capability:

- 40000 PCS/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

New products

Hot products

Related keywords