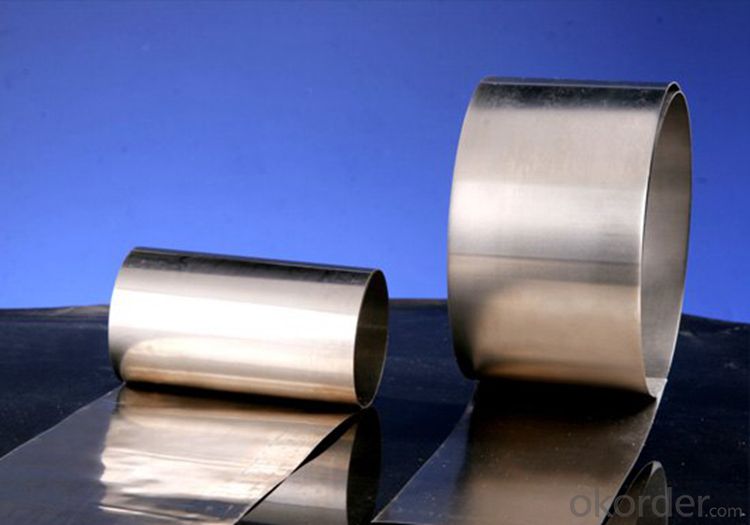

Hot Rolled,Cold Rolled Stainless Steel Coils,Steel Plates NO,1 Finish,NO.2B Finish Steel Coils

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 18 m.t.

- Supply Capability:

- 1000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

Products Description

Product | stainless steel coils/plates/sheets | ||

Discharge Port | Any Port, China | ||

Size | Coils | Cold Rolled: | Thickness0.3-8mm,Width:280-2100mm |

Hot Rolled : | Thickness3-14mm,Width:650-2100mm | ||

Plates | Thickness2-80mm,Width:1500-3000mm | ||

Coil Weight | About 20 Tons | ||

Grade | 201,202,304/304L/304H,316/316L/316H,321/H,310S,409/L,430 etc. | ||

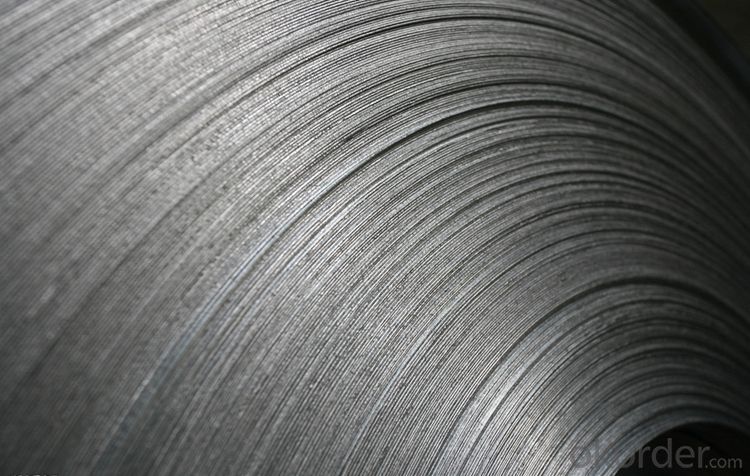

Technique | Hot Rolled/Cold Rolled | ||

Finish | 2B, BA, 2D, No1, No2, No4,NO.8,SB etc | ||

Edge | Mill Edge / Slitting Edge | ||

Package | In bundles, or as customer's requirement | ||

Place of Origin | Made in China | ||

MOQ | 20 Tons | ||

Payment Terms | 100% LC at sight,or 30%TT in advance, balance against B/L copy | ||

Delivery Time | With 30-40 days after deposit | ||

Packaging & Delivery

Packaging Detail | Standard export packing or following customer's demand |

Delivery Time | Within 30-40 days after deposit or according to the order quantity |

Detail picture of Products:

Application:

Finish | Definition | Application |

2B | Those finished, after cold rolling, by heat treatment, pickling or other equivalent treatment and lastly by cold rolling to given appropriate luster. | Medical equipment, Food industry, Construction material, Kitchen utensils. |

BA | Those processed with bright heat treatment after cold rolling. | Kitchen utensils, Electric equipment, Building construction. |

NO.3 | Those finished by polishing with No.100 to No.120 abrasives specified in JIS R6001. | Kitchen utensils, Building construction. |

NO.4 | Those finished by polishing with No.150 to No.180 abrasives specified in JIS R6001. | Kitchen utensils, Building construction, Medical equipment. |

NO.1 | The surface finished by heat treatment and pickling or processes corresponding there to after hot rolling. | Chemical tank, pipe. |

FAQ

Q: How long is the delivery time?

A: Normally 30-40 days, but mostly according to the specific requirements or the quantity

Q: Could you send me sample?

A: We can supply you with the sample for free, but the delivery charges will be covered by customers.

- Q:What are the limitations of using stainless steel sheets?

- There are several limitations associated with using stainless steel sheets. Firstly, stainless steel sheets can be quite expensive compared to other materials. This can make it less feasible for certain budget-conscious projects or applications. Secondly, stainless steel sheets are relatively heavy, which can make them difficult to handle and install, especially in large quantities. This can increase labor costs and require additional equipment for transportation and installation. Thirdly, stainless steel sheets are prone to scratching and denting. While stainless steel is known for its durability, it is not entirely resistant to physical damage. Scratches and dents can diminish the appearance and functionality of the sheets, particularly in high-traffic areas or environments where there is a risk of impact. Additionally, stainless steel sheets can be susceptible to corrosion, although to a lesser extent compared to other metals. In certain conditions, such as exposure to saltwater or harsh chemicals, stainless steel sheets may develop rust or other forms of corrosion. Regular maintenance and proper care are necessary to prevent or minimize this issue. Another limitation is that stainless steel sheets have limited color options. They generally come in shades of silver or gray, which may not be suitable for projects that require specific colors or aesthetics. Lastly, stainless steel sheets have poor insulation properties. They conduct heat and cold more efficiently than other materials, which can result in greater energy loss and higher heating or cooling costs. In applications where insulation is crucial, additional measures or alternative materials may be required. In conclusion, while stainless steel sheets offer numerous advantages such as strength, corrosion resistance, and durability, they also have limitations in terms of cost, weight, susceptibility to damage, corrosion, limited color options, and poor insulation properties. Understanding these limitations is crucial when considering the use of stainless steel sheets in various applications.

- Q:Stainless steel plate laser cutting how to charge?

- It depends on which laser machine you use, and the specific model, and the processing materials are also different. Consumption is mainly: electricity, laser gas, auxiliary gas, consumables, general machine tool software has billing function, but not allowed.

- Q:How do you prevent galling on stainless steel sheets?

- To prevent galling on stainless steel sheets, it is important to use lubricants or anti-seize compounds during the manufacturing or assembly process. This helps reduce friction and surface adhesion, minimizing the risk of galling. Additionally, using proper cutting tools and techniques, such as slow speeds and low feed rates, can also help prevent galling.

- Q:Can stainless steel sheets be used for brewery tanks?

- Yes, stainless steel sheets are commonly used for brewery tanks. Stainless steel is a preferred material in the brewing industry due to its corrosion resistance, durability, and ease of cleaning. It is an ideal choice for tanks that require high sanitary standards and frequently come in contact with acidic or caustic substances.

- Q:What are the different types of colored finishes available for stainless steel sheets?

- There are several different types of colored finishes available for stainless steel sheets. These finishes are designed to enhance the appearance of stainless steel and provide various aesthetic options. Some of the most common colored finishes include: 1. Mirror Finish: This finish is highly reflective and creates a mirror-like surface on stainless steel sheets. It is achieved by polishing the stainless steel surface to a high gloss. Mirror finishes are commonly used in decorative applications and provide a sleek and modern look. 2. Satin Finish: Also known as brushed or matte finish, this type of finish has a smooth, non-reflective surface. It is achieved by brushing the stainless steel surface with an abrasive material. Satin finishes are commonly used in architectural and industrial applications and provide a clean and contemporary appearance. 3. Colored Powder Coating: Powder coating involves applying a dry powder to the stainless steel surface and then curing it under heat. This process creates a durable and uniform colored finish. Colored powder coatings are available in a wide range of hues, allowing for customization and versatility in design. 4. PVD Coating: Physical Vapor Deposition (PVD) is a process that involves depositing a thin layer of metal onto the stainless steel surface. This coating can be in various colors, such as gold, bronze, black, or rose gold. PVD coatings provide excellent durability and resistance to wear, making them suitable for high-traffic areas or decorative applications. 5. Colored Anodizing: Anodizing is an electrochemical process that creates a protective oxide layer on the stainless steel surface. By using dyes during the anodizing process, a wide range of colors can be achieved. Colored anodized finishes are known for their corrosion resistance and can be utilized in architectural or design-oriented applications. Each of these colored finishes offers unique characteristics and can be chosen based on the desired aesthetic, durability, and specific application requirements. It is important to consider factors such as the level of maintenance needed, environmental conditions, and the intended use of the stainless steel sheets when selecting a colored finish.

- Q:What are the different types of brushed finishes available for stainless steel sheets?

- There are several different types of brushed finishes available for stainless steel sheets, each with its own unique appearance and texture. Some of the most common types include: 1. #4 Brushed Finish: This is the most popular and widely used brushed finish for stainless steel sheets. It has a smooth, directional grain that is achieved by using a grit belt or wheel. The resulting finish is commonly referred to as a satin finish. 2. #6 Brushed Finish: This is a finer brushed finish compared to the #4 finish. It is achieved by using a higher grit abrasive belt or wheel, resulting in a smoother and more refined appearance. It is often used for decorative purposes or in applications where a higher level of sophistication is desired. 3. #8 Mirror Finish: This is a highly reflective brushed finish that resembles a mirror. It requires extensive polishing and buffing to achieve a near-perfect reflective surface. It is commonly used in architectural and decorative applications where a polished and glamorous appearance is desired. 4. Bead Blasted Finish: This finish is achieved by blasting stainless steel sheets with glass beads under high pressure. The process creates a uniform, textured surface with a matte appearance. It is often used in applications where a non-reflective, low maintenance finish is desired. 5. Linen Finish: This finish is characterized by a pattern of parallel lines that resemble linen fabric. It is achieved by using a combination of abrasive belts or wheels with different grit sizes, resulting in a textured and visually appealing finish. It is commonly used in architectural and interior design applications. These are just a few examples of the different types of brushed finishes available for stainless steel sheets. The choice of finish will depend on the desired aesthetic, functionality, and application requirements.

- Q:Can stainless steel sheets be used for kitchen appliances?

- Kitchen appliances can indeed utilize stainless steel sheets. The reason behind its popularity in this realm is its robustness, ability to resist corrosion, and effortless upkeep. Ovens, refrigerators, dishwashers, and other kitchen appliances are often crafted with this versatile material. It can be effortlessly molded into diverse shapes and sizes, accommodating a variety of appliance designs. Furthermore, stainless steel's sleek and contemporary aesthetics have made it the preferred option for countless homeowners and chefs.

- Q:What's the difference between the 304 stainless steel plate and the 310S stainless steel plate?

- 304 is a versatile stainless steel which is widely used in the manufacture of equipment and parts requiring good overall performance (corrosion resistance and formability). In order to maintain the inherent corrosion resistance of stainless steel, steel must contain more than 18% chromium, more than 8% of the nickel content. 304 stainless steel is a brand of stainless steel produced according to the ASTM standard in the United states.310S stainless steel austenitic chromium nickel stainless steel has good oxidation resistance, corrosion resistance, because the higher percentage of chromium and nickel, which has much better creep strength, can continuously work under high temperature, good heat resistance, softening temperature is more than 800[1], and the allowable stress continued to decrease, the highest use temperature of 1200 DEG C. For Ni (Ni), chromium (Cr) content is high, with good oxidation resistance, corrosion resistance, acid and alkali resistance, high temperature performance, high temperature resistant steel dedicated to the manufacture of electric furnace tube and so on, increase the amount of carbon austenitic stainless steel, due to the solid solution strengthening effect to the strength improved, chemical composition characteristics of austenitic stainless steel is chrome, nickel based addition of molybdenum and tungsten, niobium and titanium elements, as its face centered cubic structure, and strength and high creep strength at high temperature.

- Q:Can stainless steel sheets be used for pharmaceutical storage cabinets?

- Yes, stainless steel sheets can be used for pharmaceutical storage cabinets. Stainless steel is highly resistant to corrosion, making it an ideal material for storing pharmaceuticals, which often require sterile and hygienic conditions. Stainless steel is also easy to clean and maintain, ensuring that the storage cabinets remain contamination-free. Additionally, stainless steel is durable and long-lasting, providing a reliable and secure storage solution for pharmaceuticals.

- Q:Can stainless steel sheets be used for medical instrument trays?

- Indeed, medical instrument trays can make use of stainless steel sheets. The medical industry frequently utilizes stainless steel because of its remarkable resistance to corrosion, durability, and ease of cleaning. Medical instrument trays serve the purpose of storing and arranging diverse medical instruments during procedures. Stainless steel sheets are well-suited for this task due to their non-reactive nature and ability to withstand frequent sterilization processes, such as autoclaving. Furthermore, stainless steel possesses a sleek surface that can withstand scratches and dents, ensuring that the trays remain hygienic and easy to clean. All in all, stainless steel sheets prove to be a dependable and appropriate material option for medical instrument trays.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Hot Rolled,Cold Rolled Stainless Steel Coils,Steel Plates NO,1 Finish,NO.2B Finish Steel Coils

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 18 m.t.

- Supply Capability:

- 1000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords