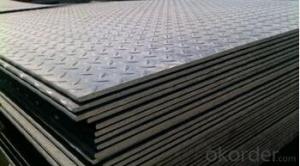

Hot Rolled checkered plate Coils/Sheets Q235/SS400/ST 37-2

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 200000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product: | Hot Rolled Steel Coils/Sheets |

Material: | Q195,Q235,A36,SS400,S235JR,Q345,ST37-2, CCSB etc |

Standard : | JIS G3002 GB/T251B |

Technique: | hot rolled |

Thickness | 1.2mm to 200mm |

Tolerance of thickness: | :+/-0.03mm |

Width: | 750mm-2000mm |

Tolerance of width: | :+/-5.00mm (aiming to +/-2.00mm) |

Normal width: | 914mm, 1000mm, 1200mm, 1219mm, 1250mm,1500mm |

Length: | According to requirement |

Coil ID: | 508mm-610mm |

Coil Weight: | 10-25 Metric Tons |

Surface: | Black, Chromate, fingerprint resistant treatment, slight oiled or non-oiled, dry |

Port of Loading: | Tianjin/Shanghai port |

Packaging Details: | Standard export packing or according to the clients required |

Delivery Time | Within 30 days after received 30% deposit or workable L/C |

Payment Terms: | L/C,T/T |

- Q:Are steel sheets suitable for roofing?

- Indeed, steel sheets make an ideal roofing material. Steel, being both sturdy and durable, can endure even the harshest weather conditions, including heavy rainfall, snow, and strong winds. Moreover, it boasts fire resistance, pest resistance, and rot resistance, making it a trustworthy option for long-lasting roofing solutions. In addition to these advantages, steel sheets are lightweight and simple to install, leading to reduced labor and installation expenses. Furthermore, they are available in a wide range of colors and finishes, enabling customization to suit the aesthetic of any structure. All in all, steel sheets offer exceptional protection and durability, which explains their popularity in roofing applications.

- Q:Can steel sheets be used in food processing industries?

- Yes, steel sheets can be used in food processing industries. Stainless steel sheets are commonly used in food processing industries due to their many beneficial properties. Stainless steel is resistant to corrosion, which is essential in an environment where food is processed, as it prevents contamination and ensures the safety of the final product. Steel sheets are also easy to clean and maintain, making them ideal for use in industries where hygiene is of utmost importance. Additionally, stainless steel is non-reactive to food, meaning it does not leach any harmful chemicals into the processed food. Steel sheets are versatile and can be used for various applications in food processing industries, such as countertops, worktables, shelving, and equipment surfaces.

- Q:Are steel sheets suitable for flooring applications?

- Yes, steel sheets are suitable for flooring applications. Steel sheets offer many advantages that make them an ideal choice for flooring. Firstly, steel sheets are extremely durable and can withstand heavy loads and high foot traffic. They are resistant to wear and tear, making them long-lasting and cost-effective in the long run. Additionally, steel sheets are fire-resistant, which enhances the safety of the flooring. They are also resistant to moisture, making them suitable for areas with high humidity or where water may be present. Furthermore, steel sheets are easy to clean and maintain, requiring minimal effort and cost for upkeep. They are available in a variety of sizes, thicknesses, and finishes, allowing for customization to suit different flooring requirements. Overall, steel sheets offer a strong, durable, and versatile flooring option that can be used in various applications, including industrial, commercial, and residential settings.

- Q:Can the steel sheets be easily painted or coated?

- Yes, steel sheets can be easily painted or coated. The smooth surface of steel sheets allows for excellent adhesion of paint or other coatings. Prior to painting or coating, it is important to clean the surface thoroughly to remove any dirt, grease, or rust that may affect the adhesion. Additionally, applying a primer or a base coat can further enhance the durability and longevity of the paint or coating. Overall, steel sheets provide a suitable and easily paintable surface for a variety of applications.

- Q:What are the different forms of steel sheets (flat, perforated, expanded, etc.)?

- Steel sheets are available in various forms to suit different applications and requirements. Some of the different forms of steel sheets include: 1. Flat Steel Sheets: These sheets have a smooth and flat surface and are commonly used in construction, fabrication, and manufacturing industries. They are versatile and can be easily cut, shaped, and formed into various products. 2. Perforated Steel Sheets: These sheets feature small holes or perforations that are evenly spaced. They are commonly used for filtration, ventilation, and decorative purposes. Perforated steel sheets provide excellent airflow and visibility while maintaining structural integrity. 3. Expanded Steel Sheets: These sheets are created by cutting and stretching a flat sheet of steel, resulting in a mesh-like pattern. Expanded steel sheets are lightweight, strong, and provide excellent ventilation and drainage. They are commonly used in walkways, gratings, fencing, and security applications. 4. Galvanized Steel Sheets: These sheets are coated with a layer of zinc, which provides excellent corrosion resistance. Galvanized steel sheets are commonly used in outdoor applications where exposure to moisture and harsh weather conditions is a concern. 5. Stainless Steel Sheets: These sheets are made from an alloy of steel and chromium, which provides excellent corrosion resistance and high tensile strength. Stainless steel sheets are commonly used in the food industry, transportation, medical equipment, and architectural applications. 6. Cold Rolled Steel Sheets: These sheets are produced by rolling steel at room temperature, resulting in a smooth and even surface. Cold-rolled steel sheets have improved surface finish, dimensional accuracy, and strength. They are commonly used in automotive, appliances, and furniture industries. 7. Hot Rolled Steel Sheets: These sheets are produced by heating steel above its recrystallization temperature and then rolling it. Hot-rolled steel sheets have a rougher surface and are more malleable compared to cold-rolled sheets. They are commonly used in structural components, construction, and general fabrication. These are just a few examples of the different forms of steel sheets available. Each type of steel sheet has its own unique properties and advantages, making them suitable for various applications and industries.

- Q:Are steel sheets suitable for solar panel mounting?

- Yes, steel sheets are suitable for solar panel mounting. They provide a strong and stable base for the panels, ensuring they are securely installed and can withstand various weather conditions. Additionally, steel sheets are durable and long-lasting, making them a reliable choice for solar panel mounting systems.

- Q:Can steel sheets be used for industrial machinery parts?

- Yes, steel sheets can be used for industrial machinery parts. Steel sheets are commonly used in the manufacturing of industrial machinery parts due to their strength, durability, and versatility. They can be easily cut, bent, and formed into various shapes to meet the specific requirements of different machinery components. Additionally, steel sheets offer excellent resistance to wear, corrosion, and heat, making them suitable for use in demanding industrial environments.

- Q:Can steel sheets be recycled after their useful life?

- Yes, steel sheets can be recycled after their useful life. Steel is one of the most commonly recycled materials in the world, and the recycling process for steel sheets involves melting them down to create new steel products. This not only helps conserve natural resources but also reduces waste and the environmental impact of steel production.

- Q:Can steel sheets be used for manufacturing security doors?

- Indeed, security doors can be manufactured using steel sheets. Steel, being a robust and long-lasting material, offers exceptional security and safeguarding. It possesses the ability to withstand forced entry attempts and provides resistance against break-ins. Due to their remarkable tensile strength, steel sheets are frequently employed in the construction of security doors as they are difficult to bend or break. Moreover, steel doors can be further reinforced with various additional features, including multiple locks, deadbolts, and security bars, to enhance their security capabilities. All in all, steel sheets serve as a dependable option for the production of security doors.

- Q:What are the standard sizes for steel sheets?

- The standard sizes for steel sheets vary depending on the specific type of steel and its intended use, but common sizes range from 4 feet by 8 feet to 6 feet by 10 feet.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Hot Rolled checkered plate Coils/Sheets Q235/SS400/ST 37-2

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 200000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords