Hot Rolled Aluminum Alloy Roofing Sheet with Best Price

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

1.Structure of Hot Rolled Aluminum Alloy Roofing Sheet Description:

Hot Rolled Aluminum Alloy Roofing Sheet is produced advanced technology. Selecting qualified materials and the products have been tested and approved by National Test and Inspection Center for Building Materials, and also tested and approved by European and American Quality Testing System, in accordance with GB/T17748-1999 standards. As one of the international famous brands, IDEABOND developed and researched new products on the basis of aluminum-plastic plate, including fireproof aluminum-plastic composite plate, titanium zinc composite plate, titanium compound plate and stainless steel composite plate etc.

2.Main Features of Hot Rolled Aluminum Alloy Roofing Sheet:

Good Corrosion Resistance

Good Machinability

High Quality

Competitive Price

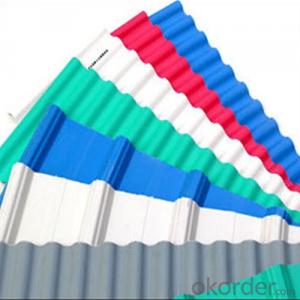

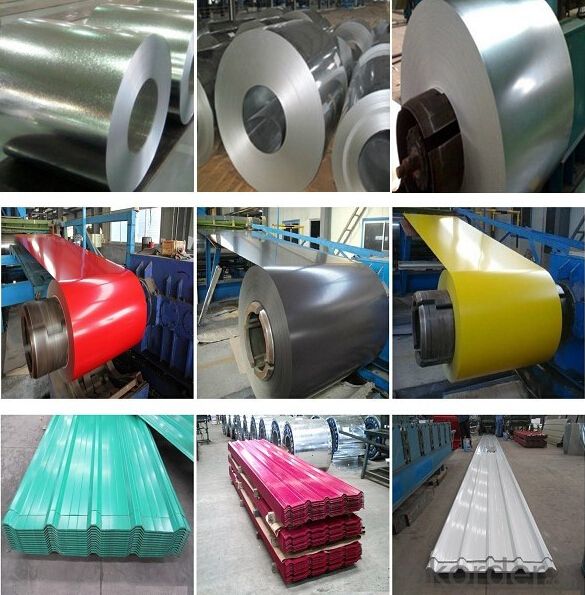

3. Hot Rolled Aluminum Alloy Roofing Sheet Images:

4. Hot Rolled Aluminum Alloy Roofing Sheet Specification:

| Alloy No. | Thickness (mm) | Width (mm) | Length (mm) | Temper | |

| A1050,A1060, A1070,A1100 | 0.2-100 | 20-2200 | 20-8000 | O,H12,H22,H14,H16,H18, H24,H26,etc | |

| 3A21,A3003,A3105,A3004 | 0.2-100 | 20-2200 | 20-8000 | O,H14,H18,H24,etc | |

| A5052 ,A5005,A5083,A5754 | 0.2-100 | 20-2200 | 20-8000 | O,H18,H24,H32,H34,H111,H112 ,etc | |

| A6061,A6082,A6063 | 0.2-200 | 20-2200 | 20-8000 | T4,T6, T651,etc | |

| A8011 | 0.2-100 | 20-2200 | 20-8000 | O,H12,H22,H14,H16,H18,H24,H26, etc | |

5.FAQ

Q1.How long have you been in this product?

A1:More than 10 years.

Q2. What's the minium quantity(MOQ)?

A2. 5 Metric tons

Q3. How long is shipping time?

A3. 7 (ready-made products)-25 days(OEM)

Q4. How do you guarantee the quality?

A4. 1. Cooperating and Exchaning experience with sevral quoted aluminum companies

2. Japanese and Swiss production line and skilled works (regular training and testing)

3. more than 10 years production experience.

Q5. Do you have after sale service?

A5. Yes. Any quality problem occurs within one year, pls take photoes,we will be responsible.

- Q:What are the different methods of polishing aluminum sheets?

- Polishing aluminum sheets can be done through various methods, each with its own pros and cons. Here are some commonly used techniques: 1. Manual polishing: By employing sandpaper or abrasive pads, one can manually rub the surface of the aluminum sheet to achieve a high level of shine and smoothness. However, this method demands physical effort and can be time-consuming, especially for larger sheets. Careful execution is crucial to avoid leaving behind scratches or marks. 2. Chemical polishing: Dissolving a thin layer of the aluminum surface using chemical compounds can result in a smoother and shinier finish. This method is suitable for larger sheets or complex shapes where manual polishing is impractical. However, chemical handling must be meticulous, and it may not be suitable for certain aluminum alloys. 3. Electropolishing: An electrochemical process involving the use of an electric current to remove a thin layer of material from the aluminum surface. This method guarantees a smooth and shiny finish for both small and large sheets. It is particularly effective in eliminating surface imperfections and achieving a uniform appearance. However, specialized equipment and expertise are required to properly control the process. 4. Vibratory finishing: Placing aluminum sheets in a vibratory machine with abrasive media, like ceramic or plastic chips, can help remove surface imperfections and achieve a polished finish. This method is ideal for large batches of sheets and can be cost-effective. Nevertheless, it may not produce the same level of shine as other methods. 5. Buffing and polishing compounds: These compounds are applied to the aluminum sheets and then buffed using a rotary tool or polishing machine. The abrasive particles in the compounds aid in removing scratches and enhancing the metal's shine. This method is relatively quick and easy, but it may not be as effective for significant oxidation or deep scratches. Ultimately, the choice of polishing method depends on factors such as the size and type of the aluminum sheets, desired level of shine, and available equipment and expertise. It is advisable to test different methods on a small area before proceeding with the full polishing process to ensure satisfactory results.

- Q:Are aluminum sheets suitable for aerospace applications?

- Yes, aluminum sheets are highly suitable for aerospace applications. Aluminum is widely used in the aerospace industry due to its excellent combination of strength, lightweight properties, and corrosion resistance. Its high strength-to-weight ratio makes it an ideal choice for constructing aircraft structures, including fuselages, wings, and other critical components. Aluminum sheets also offer good formability, allowing for complex shapes to be easily manufactured. Additionally, aluminum has good thermal conductivity, which is beneficial for heat dissipation in aerospace applications. Overall, aluminum sheets meet the stringent requirements of the aerospace industry and are extensively utilized in the construction of modern aircraft.

- Q:What are the weight-saving benefits of using aluminum sheets in different applications?

- There are several weight-saving benefits of using aluminum sheets in different applications. Firstly, aluminum is a lightweight metal, with a density much lower than other commonly used materials such as steel. This means that by replacing steel sheets with aluminum sheets, significant weight reduction can be achieved in various applications. The reduced weight of aluminum sheets is particularly advantageous in transportation industries. For example, in the automotive sector, using aluminum sheets for body panels, chassis components, and other structural parts can significantly lighten the vehicle's overall weight. This weight reduction leads to improved fuel efficiency, as less energy is required to move the lighter vehicle. Additionally, lighter vehicles generally have better acceleration, handling, and braking performance. In the aerospace industry, the weight-saving benefits of aluminum sheets are even more crucial. Every extra kilogram of weight on an aircraft can increase fuel consumption, and thus operating costs. By utilizing lightweight aluminum sheets in the construction of aircraft structures, such as wings, fuselages, and engine components, the overall weight of the aircraft can be reduced, resulting in improved fuel efficiency and extended flight range. Another industry where the weight-saving benefits of aluminum sheets are highly valued is the construction sector. Aluminum sheets are often used in the construction of buildings and infrastructure due to their lightweight nature. This lightweight characteristic not only makes installation easier but also reduces the overall load on the building's foundation. Moreover, using aluminum sheets in construction can also lead to cost savings, as lighter materials require less support structure and can be transported more efficiently. Furthermore, the weight-saving benefits of aluminum sheets extend to various other applications such as packaging, electronics, and consumer goods. In packaging, aluminum sheets are commonly used for lightweight and flexible packaging materials, reducing shipping costs and environmental impact. In electronics, aluminum sheets are used in devices like laptops and smartphones, where weight reduction is desirable for portability. Lastly, in consumer goods, aluminum sheets are utilized for producing lightweight and durable products, such as furniture, cookware, and sports equipment. In conclusion, the weight-saving benefits of using aluminum sheets in different applications are significant. The lightweight nature of aluminum allows for reduced weight in transportation industries, improved fuel efficiency, better performance, and extended flight range in aerospace applications, cost savings and easier installation in construction, as well as various advantages in packaging, electronics, and consumer goods. Overall, aluminum sheets offer a versatile and efficient solution for achieving weight reduction and enhancing performance in diverse industries.

- Q:Does Aluminum Foil really work to help beat the summer heat?I live in San Diego which is known for having perfect weather pretty much all year round, but just yesterday we are starting to get some record breaking heat. Most apartments, condos, and houses do not have A/C because like I just mentioned it's usually in the high 60s or low 70s during the spring and summer, perfect.Will Aluminum Foil work or can someone else suggest anything else?!PLEASE note that I'm just putting aluminum foil on my bedroom window which just faces some other apartment complex and I am not concerned with the aesthetics. I might consider putting something up (but just not sure what) on the living room window other than aluminum foil since everyone can see that window.

- The aluminum foil does work, shiny side out. It just reflects some of that bright afternoon sun to keep the room from heating up. I use a window film I found at Home Depot that is UV filtering that works too. You cut it close to size, spray the window with water put it on. You squeegy out the water get rid of the bubbles and use a razor to trim it to exact size. Both of these work, it just depends on whether or not you want to eleminate any light that comes into the room or not.

- Q:How do I cut aluminum sheets?

- To cut aluminum sheets, you will need a few tools and precautions. Here's a step-by-step guide to help you through the process: 1. Safety first: Always wear protective gear, including safety glasses, gloves, and a dust mask to protect yourself from the metal shavings. 2. Choose the right tool: There are a few options for cutting aluminum sheets, depending on their thickness. For thin sheets (up to 1/8 inch), a manual hand shear or a utility knife with a sharp blade can be sufficient. For thicker sheets, you may need power tools such as a jigsaw, circular saw, or a specialized aluminum-cutting saw. 3. Measure and mark: Use a measuring tape, ruler, or a straightedge to determine the desired size of the sheet. Mark the cutting line on the sheet using a permanent marker or a scribe. 4. Secure the sheet: Use clamps to secure the aluminum sheet firmly to a workbench or a cutting surface. This will prevent the sheet from moving during the cutting process, ensuring accurate cuts. 5. Cutting with a hand shear or utility knife: For thin sheets, start by aligning the cutting edge of the shear or utility knife with the marked line. Apply firm and even pressure to make a straight cut. If using a utility knife, you may need to score the sheet several times before it breaks off. 6. Cutting with power tools: If using a jigsaw, circular saw, or an aluminum-cutting saw, make sure you have the appropriate blade for cutting metal. Set the saw's cutting depth slightly deeper than the thickness of the aluminum sheet. Align the blade with the marked line and slowly guide the saw along the cutting path, ensuring a smooth and steady motion. Apply light pressure and let the saw do the work. 7. Finishing touches: Once the cut is complete, inspect the edge for any burrs or roughness. Use a metal file or sandpaper to smooth out any imperfections. Remember, practice caution and take your time when cutting aluminum sheets. It's always a good idea to test your cutting method on a small scrap piece before proceeding with the actual sheet.

- Q:Can aluminum sheets be polished for a mirror-like finish?

- Yes, aluminum sheets can be polished to achieve a mirror-like finish. Aluminum is a relatively soft metal and can be easily polished to a high shine. The process typically involves sanding the surface with progressively finer grits of sandpaper, followed by buffing with polishing compounds and a soft cloth or a polishing wheel. The goal is to remove any scratches or imperfections on the surface and create a smooth, reflective finish. With the right techniques and tools, aluminum sheets can be polished to a mirror-like shine, making them suitable for various applications such as decorative purposes, automotive parts, or reflective surfaces in optical devices.

- Q:Can aluminum sheets be laminated?

- Yes, aluminum sheets can be laminated. Lamination involves bonding a layer of material, such as plastic or paper, to the surface of the aluminum sheet to provide protection, enhance aesthetics, or improve functionality.

- Q:I am following a recipe for braised ribs that calls for wrapping the ribs in heavy duty aluminum foil. I don't have heavy duty, so can regular aluminum foil be used as a replacement?

- I'd at least double it, if not triple it in thickness for cooking ribs. Single ply regular aluminum foil won't give you the result you're looking for.

- Q:What are the different methods of surface cleaning aluminum sheets?

- There are several different methods for surface cleaning aluminum sheets, including chemical cleaning, mechanical cleaning, and electrolytic cleaning. Chemical cleaning involves using solutions or acids to remove dirt, oxidation, or other contaminants from the surface of the aluminum. Mechanical cleaning involves scrubbing or abrasive techniques to physically remove dirt or grime from the surface. Electrolytic cleaning utilizes an electric current and an electrolyte solution to remove contaminants and create a clean surface on the aluminum sheets.

- Q:I have to repair a cracked aluminum engine block. What alumunum epoxy should I use?

- Best Epoxy For Aluminum

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Hot Rolled Aluminum Alloy Roofing Sheet with Best Price

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords