Hot Items 1, 3, 5 Ultra Thick Aluminium Sheet

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2.5

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

Hot Items 1, 3, 5 Ultra Thick Aluminium Sheet

l Product Information

Product | Alloy designation | Supply status | Thickness(mm) | Width(mm) | length(mm) |

Quench aluminium plate | 2 series, 6 series, 7 series | T3,T4,T42, T6,T62,T73, T74 | 0.5~150 | Under 2000 | Under 11000 |

Pre-stretching version plate | 1~8 series | Various forms | 2.0~180 | Under 1600 | Under 4000 |

Checkered plate | 1 series, 3 series, 5 series | H224,H114, O,H234 | 1.0~8.0 | Under 1900 | Under 12000 |

Hot rolled plate | 1~8 series | F,H111,H112 | 4.0~300 | Under 2200 | Under 11000 |

Hot rolled stock | 1~8 series | F,H111,H112 | 4.0~15 | Under 2300 | C |

Plate | 1~8 series | Various forms | 0.15~300 | Under 2200 | Under 12000 |

Coiled material | 1~8 series | Various forms | 0.15~15 | Under 2200 | C |

Air-conditioning foil | 8011,3012 | H22,H24 | 0.09~0.15 | Under 1300 | C |

Curtain wall plate | 1060,1050 , 1100,3003 3004,5052 | H14,H24,O | 1.0~5.0 | Under 2200 | Under 12000 |

Aluminium foil | 1060,1100, 8011,1235, 3003 | Various forms | 0.008~0.2 | Under 1500 | C |

l Packaging & Delivery

Packaging detail: Standard seaworthy exporting carton, Wooden pallets, waterproof paper and plastic coverage or as customer's requirements

Delivery detail: about 25 days from received oiginal L/C or advance payments

l Company Profile

CNBM International Corporation, China National Building Materials (Group) Corporation, is one of the largest companies in China building material & equipment industry, with 42,800 employees and sales in 2005 of US Dollar 4.395 billion. In 2006, China National Building Material Company Limited was listed on Hong Kong Stock Market with the stock code as 3323. |

l CNBM World Wide

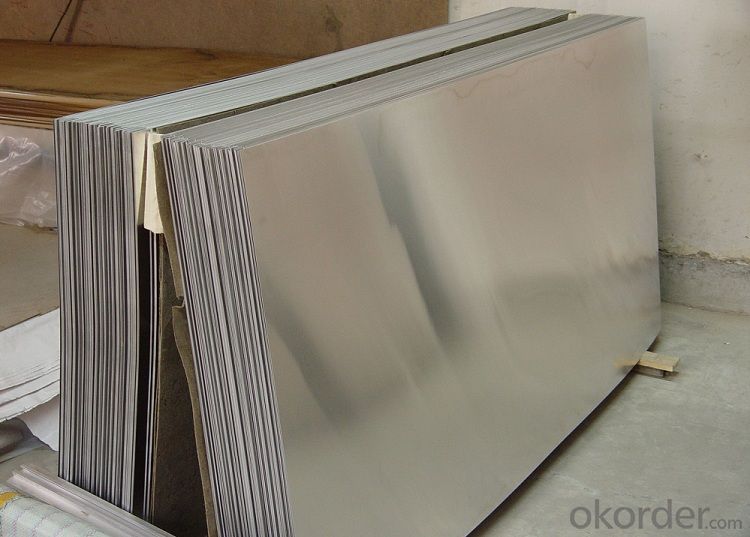

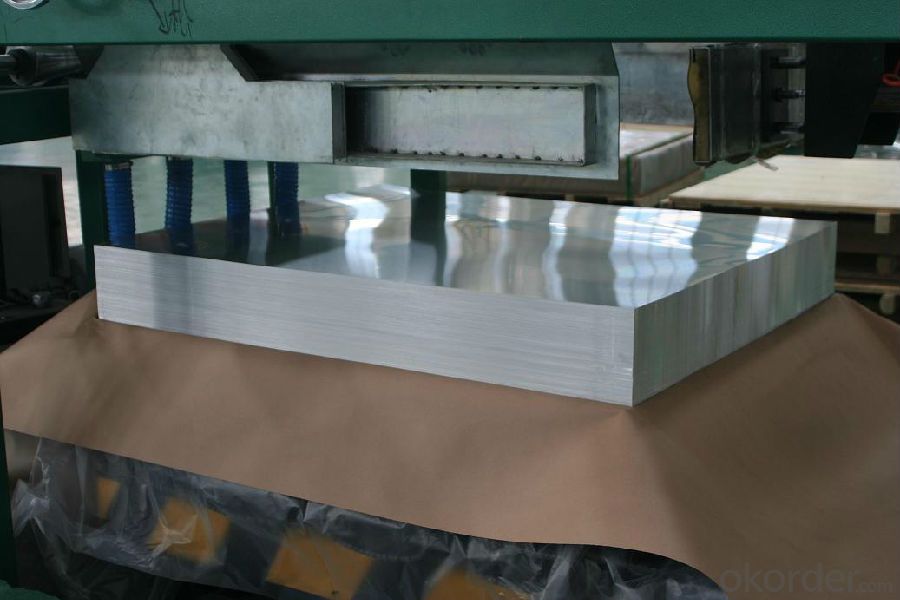

l Product Images

l Certificates

l FAQ

Q: Do you provide free samples?

A: Yes, free samples will be sent to you on freight at destination.

Q: Can I get your latest products catalogue?

A: Yes, it will be sent to you in no time.

Q: What is the MOQ?

A: 2.5 tons

Q: What are your payment terms?

A: We accept L/C, T/T

- Q:What are the common surface repair methods for aluminum coils?

- Common surface repair methods for aluminum coils include sanding, buffing, and polishing. Sanding is used to remove surface imperfections and smooth out any rough areas. Buffing involves using a buffing wheel and compound to restore the shine and luster of the aluminum surface. Polishing is done using a polishing compound or aluminum polish to further enhance the appearance and create a protective barrier against corrosion.

- Q:How is an aluminum coil made?

- An aluminum coil is made through a process called continuous casting and rolling. First, pure molten aluminum is poured into a continuous casting machine, which creates a solidified strip of aluminum. This strip is then fed through a series of rolling mills, where it undergoes multiple passes to achieve the desired thickness and shape. The rolling process also helps in improving the mechanical properties of the aluminum coil. Finally, the coil is coiled up and is ready to be used for various applications such as in construction, automotive, or packaging industries.

- Q:What is the maximum length of aluminum coils?

- The maximum length of aluminum coils may vary due to multiple factors, including the specific manufacturing process, capabilities of equipment, and industry standards. However, in general, aluminum coils can range in length from a few hundred feet to several thousand feet. They find common use in applications like roofing, HVAC systems, and electrical wiring. Additionally, it should be noted that transportation and handling considerations may also impose limitations on the maximum length of aluminum coils.

- Q:Can aluminum coils be used for food storage and processing?

- Yes, aluminum coils can be used for food storage and processing. Aluminum is a popular choice for food storage and processing due to its many beneficial properties. It is lightweight, strong, and resistant to corrosion, which makes it ideal for maintaining the quality and freshness of food. Aluminum coils can be used to manufacture various food storage and processing equipment such as containers, pans, trays, and foil. Additionally, aluminum has excellent thermal conductivity, which allows for efficient cooling and heating of food. It is also impermeable to light, moisture, and oxygen, which helps to protect food from spoilage and contamination. Overall, aluminum coils are a reliable and safe option for food storage and processing applications.

- Q:Can aluminum coils be customized or fabricated into specific shapes?

- Yes, aluminum coils can be customized or fabricated into specific shapes. Aluminum has excellent formability and can be easily shaped using various fabrication techniques such as rolling, bending, stamping, and extrusion. These processes allow the aluminum coils to be transformed into specific shapes, such as sheets, plates, tubes, and profiles, to meet the specific requirements of different applications. Additionally, aluminum can also be welded, joined, or cut to further customize its shape and size. This versatility in customization makes aluminum coils a preferred choice in various industries, including automotive, aerospace, construction, and manufacturing.

- Q:i need ONE advantage of each, and a final reason why aluminium is used?

- Copper does conduct slightly better than aluminum, but aluminum corrodes over time and the oxidized surface has very high resistance. Copper also oxidizes but is not as high a resistance. The high resistance, when in contact with another conductor, like a junction inside a box, will create heat. Those high resistance junctions create so much heat that over time a fire hazard develops. Hence, National Electrical Code disallowed the use of aluminum for safety reasons.

- Q:Does anyone know if aluminum skateboards are good?

- aluminum skateboards are ok if your just olling and playing around on them. but if your a real skater you'll probably want to get a real one.

- Q:What are the factors that determine the price of aluminum coils?

- The factors that determine the price of aluminum coils include the current market demand and supply, the cost of raw materials, production and manufacturing costs, transportation costs, market competition, and any additional factors such as tariffs or taxes.

- Q:What are the common recycling methods for aluminum coils?

- There are several common recycling methods for aluminum coils. One of the most widely used methods is mechanical recycling, which involves shredding the aluminum coils into small pieces and then melting them down to form new aluminum coils. This method is efficient and cost-effective, as it allows for the reuse of the aluminum material without compromising its quality. Another method is called pyrolysis, which involves heating the aluminum coils at high temperatures in the absence of oxygen. This process breaks down the aluminum into its constituent elements, allowing for the recovery of valuable metals and other byproducts. Chemical recycling is another method that can be used for aluminum coil recycling. This involves dissolving the aluminum coils in a chemical solution to separate the aluminum from other materials. The resulting aluminum can then be used to manufacture new coils. Finally, there is also a method called smelting, which involves melting the aluminum coils and separating impurities through a process called electrolysis. This method allows for the recovery of pure aluminum, which can be used to make new coils. Overall, these recycling methods help to reduce the environmental impact of aluminum coil production by conserving resources and minimizing waste. They also contribute to the sustainability of the aluminum industry by promoting the reuse of materials and reducing the need for virgin aluminum production.

- Q:What is the minimum width of aluminum coils?

- Depending on specific requirements and manufacturing capabilities, the minimum width of aluminum coils can vary. Typically, aluminum coils have a minimum width ranging from approximately 0.25 inches to 0.5 inches. It is worth mentioning that specialized manufacturing processes might enable even narrower widths, although these are less frequent and may incur additional costs or limitations. Moreover, the minimum width necessary for aluminum coils will also be influenced by the specific application and industry requirements.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Hot Items 1, 3, 5 Ultra Thick Aluminium Sheet

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2.5

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords