Hot Galvanized Ringlock Scaffolding System with High Load Capacity

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Structure of Ring Lock Scaffolding Description

Ring-lock scaffolding consists of cup-lock connector,post,cross bar,diagonal brace,base and top brace.Safe and convenient to operation,fast to assemble and dismantle,widely used in scaffolding construction,such as formwork scaffold and fitment construction.

2. Main Features of the Ring Lock Scaffolding

- Using less pipes

- Easy to install

- It can be used again and again for nearly 20years

- Easy to storage and transportation

- High degree of standardization

- Easy and quick erection

- Excellent stability and bearing capacity

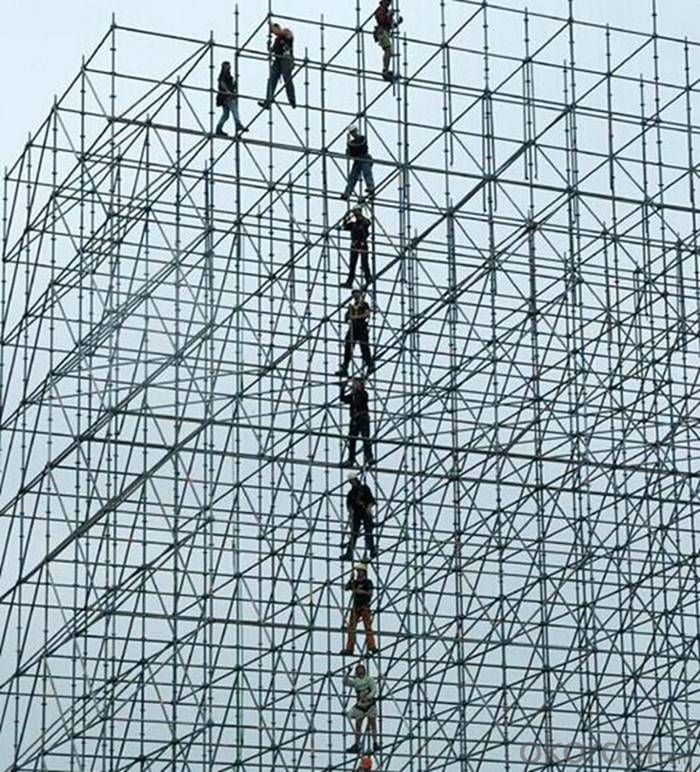

3. Ring Lock Scaffolding Images

4. Ring Lock Scaffolding Specification

• material: Q235

• tube size: 48.3*3.2mm

• surfacing: galvanized

• the usual size: 0.5-3m

We can design and manufacture as per your specific requirements.

5. FAQ of Ring Lock Scaffolding

We have organized several common questions for our clients,may help you sincerely:

1) What can we supply for you?

We can supply base jack,ring lock scaffolding system,steel pipe/tubes,etc.

2) Why choose us?

• Decade years of experience in the field of scaffoldings

• Good quality control in production process, ISO9001:2008,SGS,BV approved.

• Excellent quality and Competitive price.OEM is available.

• Available in an extensive range of stock or custom size.

• The whole process from material to finished products can be traced.

3) How about our after-sale service?

Any of your reasonable request will be responsed within 24hours.If you need the

supervision of installation,we could arrange one or two engineers to provide the technic service on-site.

4) What about the package and shipping time?

Packing: packed in wooden pallet in containers.

Shipping: We have various shipping ways for our customers, such as express,by air or by sea,railway,etc.Normally it takes around one month.

- Q:Does it matter what size your ear is when you get an industrial/scaffolding piercing?

- The size of your ear does not matter. The proper placement and jewelry length do.

- Q:I think THAT would be entertaining.

- The WWE needs Hulk Hogan to become good again!

- Q:I have to write an essay on the use of the scaffold in the novel. The first use is in the beginning when Hester is standing on it for public punishment. The third time is at the end, when Dimmesdale pleads for forgiveness and then dies. I am confused on the second time it is used. Any ideas?

- The second time is like the turning point of the novel i believe. I think it was acceptance and purging. Don't they feel better after that? Its the same principle when Dimmesdale goes through the forest and comes out feeling better. Its the beginning of them purging for their sins. I think that the second time could be labeled as confession, actually Because they all meet up and its discovered that Dimmesdale is an adulterer as well. So go with that, confession and purging, haha I read it last year; we totally did an essay on it too. (and i totally aced it! whattt) haha Hope this helps!

- Q:above the ground by pulling on a rope weighting 6lb/ft. Set up the integral of how much work is required ( only the integrand)? Let x denote the height above ground.What is the total work?

- Integral 0 to 85 [440 +(85-x)]x dx

- Q:Would you get on a window washer scaffold on a skyscraper for $1000 ?

- Sure I would. Just make sure it's in New York on the windiest day of the year.(hehe) No, really i would,we have a Welding Business and I've helped out with the steel up on Sky Risers before, it ain't a fun thing, I was out on my hands and knees crawling to the edge, but I did it.So for $1000 I would. I also would do it for more. Make sure it's CASH ONLY ,no checks and I don't take Visa or Mastercard.

- Q:Now there are many kinds of scaffolding market, like what wheel buckle scaffolding, scaffolding, scaffolding, what. I would like to buy a large number of scaffolding, and then lease out, which type of scaffolding to buy what is better?

- Now most of the crowd is the bowl buckle scaffolding, but now slowly being eliminated by the market

- Q:Specification for bowl scaffold support top rod length of not more than 30cm, which is the standard which page specific ah, too lazy to check out, who knows?

- Specification for bowl scaffold support rod top length of not more than 30cm

- Q:What is a new type of scaffolding?

- principleSocket type steel pipe scaffold with novel and beautiful, solid plug and socket welding steel as the connecting piece, Q235 steel shots component, the vertical rod is in a certain length of the rigid pipe at regular intervals on a socket welding (as shown below, the top structure) with 57 cylinder connecting rod. The cross bar is welded at the two ends of the steel pipe. The vertical rod is a vertical force member, and is composed of a horizontal rod and a tie. Connection point of the support, can withstand the bending moment, shear and torque, so as to form a space support structure is good overall stability.

- Q:What kind body jewlery would match a scaffold piercing?

- Anything as long as you match silver with silver and not with gold

- Q:In the settlement, there are also iron welded steel pipe welded pipe unit price information price, should I be in the settlement in which unit pricing is reasonable? What is the difference between these two materials? Can provide a better basis for authority. Thank you

- High efficiency: commonly used rod in the longest 3130mm, weight 17.07kg. The speed of the whole frame is 3 to 5 times faster than that of the conventional one, and the assembling and disassembling is quick and labor-saving, and the workers can complete all the operations with a hammer, which avoids the inconvenience caused by the bolt operation.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Hot Galvanized Ringlock Scaffolding System with High Load Capacity

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords