Hot Dipped Galvanized Steel Coils for Roofing Sheet SGCC (DX51D+Z)

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Description of Hot Dipped Galvanized Steel Coils for Roofing Sheet -standard:

The hot dip galvanizing process is developed from old hot plating methods, and it has a history of over 140 years since its application to the industry of France in 1836. However, the hot dip galvanizing industry has been greatly developed in recent three decades with the quick development of cold-strip steel.

2.Main features of Hot Dipped Galvanized Steel Coils for Roofing Sheet -standard:

With excellent cold-rolling steel strips as a base material, it has the advantages of

.Passivation and oil coating treatment.

.Avoids deterioration after a short-term storage in a warehouse.

.After the surface is cleaned, the product is a good base material for manufacturing anti-corrosion coating plates.

3.Hot Dipped Galvanized Steel Coils for Roofing Sheet -standard Images:

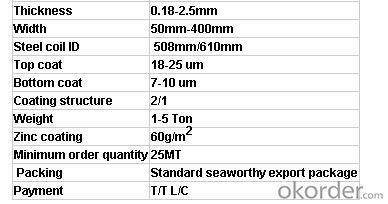

4.Hot Dipped Galvanized Steel Coils for Roofing Sheet -standard Specification:

5.FAQ

We have organized several common questions for our clients,may help you sincerely:

①How about your company?

A world class manufacturer & supplier of castings forging in carbon steel and alloy steel,is one of the large-scale professional investment casting production bases in China,consisting of both casting foundry forging and machining factory. Annually more than 8000 tons Precision casting and forging parts are exported to markets in Europe,America and Japan. OEM casting and forging service available according to customer’s requirement.

②How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

- Q:a picture of the atomic structure of carbon steel

- This is actually a quite complex question... The atomic arrangement in steels can be controlled over a pretty wide range of different structures. This is really the fundamental reason why steel is such a commonly used material. The different atomic structures produce different physical properties so metallurgists have developed many different processes to control the atomic structure to get the properties they want. One simple answer is that Fe is BCC, body centered cubic at room temperature at equilibrium conditions. When you heat Fe up, it transforms to FCC, face centered cubic. If you continue heating Fe, it goes back to BCC, then it melts. The addition of C makes these structures (and the transformation temperatures) different. Deviating from equilibrium conditions by, for example, cooling very quickly (quenching) creates different atomic structures (one of the most important is known as martensite). Depending on how much C is in the steel, you can also have two different atomic structures (two different phases) present in equilibirum, for example, pearlite which is a mix of alpha Fe (BCC) and iron carbide Fe3C (orthorombic crystal structure). So... you need to think a little more about exactly what you want a picture of. I hope this helps

- Q:What are the different types of steel coil cuts?

- There is a wide range of steel coil cuts utilized in various industries. These cuts are made during the steel manufacturing process to produce steel coils of different sizes and shapes, which can be employed for diverse applications. 1. Slit Coil: Among the most frequently employed steel coil cuts is the slit coil. This process involves cutting a large steel coil into narrower strips or slits. Slit coils are commonly utilized for applications that necessitate smaller widths, such as automotive parts, appliances, and construction materials. 2. Sheet Coil: Another type of steel coil cut is the sheet coil, which entails cutting a large coil into flat sheets. These sheets can be further processed to create different products, like roofing materials, cladding, or fabrication components. 3. Blanked Coil: The blanking process involves cutting a steel coil into custom-shaped blanks. These blanks can be used for various purposes, such as forming into different parts, stamping, or machining. Blanked coils find common usage in industries like automotive, aerospace, and manufacturing. 4. Precision Slit Coil: Precision slit coil is a specialized type of coil cut that involves cutting the steel coil with high precision and accuracy. This process ensures consistent width tolerances throughout the coil, making it suitable for applications that require precise dimensions, such as electrical components, precision tools, and automotive parts. 5. Oscillate Wound Coil: Oscillate wound coil is a unique type of steel coil cut that involves winding the steel strip in a zigzag pattern rather than a traditional flat coil. This method allows for tighter coil winding and maximizes the amount of steel on a coil. Oscillate wound coils are commonly used in industries that require high-volume production, such as stamping and roll forming. In conclusion, the diverse types of steel coil cuts cater to the specific needs of various industries, providing them with the flexibility to create products of different sizes, shapes, and dimensions.

- Q:I am in the market for a good hunting knife under $100. I am primarily looking for a knife that will keep it's edge. What type of steel should I be looking for?

- Take a close look at the Cold Steel Master Hunter. I can't wait for my hunting knife to die so I can go get one.

- Q:How are steel coils used in the production of metal partitions?

- Steel coils are an essential component in the production of metal partitions. These coils are typically made from high-quality steel and serve as the raw material for manufacturing the partitions. Firstly, the steel coils undergo a process called slitting, where they are cut into narrower strips of the desired width. This enables manufacturers to customize the size of the metal partitions according to specific project requirements. After slitting, the steel strips are then fed into a roll forming machine. This machine gradually shapes the strips into the desired profile for the metal partitions. The roll forming process involves passing the steel strips through a series of rollers, which progressively bend and form the metal into the desired shape and dimensions. Once the metal has been formed into the desired shape, it is cut into appropriate lengths to create individual partitions. These partitions are then further processed, such as through welding or spot welding, to join different components together and enhance their structural integrity. Steel coils are preferred for metal partition production due to their strength, durability, and versatility. The use of steel ensures that the partitions can withstand heavy loads, resist corrosion, and provide long-lasting performance. Additionally, steel coils offer a high degree of design flexibility, allowing for the creation of various partition styles, such as solid panels, perforated screens, or mesh partitions. Overall, steel coils play a crucial role in the production of metal partitions by providing the necessary raw material, strength, and customization options required for these versatile architectural elements.

- Q:How are steel coils cut and shaped for specific requirements?

- Steel coils are cut and shaped for specific requirements through a process called slitting and forming. Slitting involves unwinding the coil and passing it through a set of circular blades that cut it into narrower strips. These strips can then be further processed through different forming techniques such as roll forming, stamping, or bending to achieve the desired shape and dimensions. This allows manufacturers to customize steel coils according to specific requirements for various applications in industries like automotive, construction, and manufacturing.

- Q:What are the main factors that affect the quality of steel coils?

- The main factors that affect the quality of steel coils include the composition and purity of the steel, the manufacturing process, temperature control during production, and the level of surface defects or imperfections. Additionally, the storage and handling conditions, as well as the expertise of the manufacturer, can also impact the quality of the steel coils.

- Q:What are the environmental considerations associated with steel coil production?

- The environmental considerations associated with steel coil production include the extraction of raw materials, such as iron ore and coal, which can lead to habitat destruction and air/water pollution. The manufacturing process involves energy-intensive operations and emissions of greenhouse gases, contributing to climate change. Waste generated during production, such as slag and dust, can also have negative impacts on the environment if not properly managed. Additionally, the transportation of steel coils over long distances can result in carbon emissions and increase the overall environmental footprint of the product.

- Q:How do steel coils contribute to the manufacturing of HVAC systems?

- The manufacturing of HVAC systems heavily relies on steel coils, which have a critical role. These coils typically consist of high-quality steel, known for its exceptional strength, durability, and resistance to heat. Heat exchangers are one of the primary applications of steel coils in HVAC systems. These exchangers play a vital role in transferring heat between different mediums, usually air and a refrigerant. In HVAC systems, steel coils are employed in both the evaporator and condenser coils. The evaporator coil absorbs heat from the indoor air, while the condenser coil releases heat to the external environment. These coils are designed with numerous coiled tubes connected by fins. The use of steel in their construction ensures their ability to withstand high pressure and resist corrosion, guaranteeing the long-term reliability and efficiency of the HVAC system. Steel coils also contribute to the overall structural integrity of HVAC systems. They are commonly utilized in the fabrication of ductwork, responsible for distributing conditioned air throughout a building. The strength and rigidity of steel coils enable the ductwork to maintain its shape and structural integrity under various conditions, including high air pressure and temperature fluctuations. Additionally, steel coils are frequently involved in the fabrication of HVAC system cabinets and enclosures. These cabinets house several system components, including compressors, fans, and control panels. The robustness of steel coils ensures that the cabinets can withstand external forces, protect the internal components, and provide a secure housing for the entire HVAC system. To summarize, steel coils are crucial components in the manufacturing of HVAC systems. Their strength, durability, and heat resistance make them ideal for applications such as heat exchangers, ductwork, cabinets, and enclosures. By incorporating steel coils, HVAC manufacturers can produce systems that efficiently regulate temperature, enhance indoor air quality, and provide comfort in various residential, commercial, and industrial settings.

- Q:What are the different types of steel coil slitting machines?

- There are several different types of steel coil slitting machines, including rotary shear slitting machines, loop slitting machines, and tension slitting machines. Each type has its own unique features and advantages, but they all serve the purpose of cutting steel coils into narrower strips.

- Q:What are the common applications of steel coils in construction?

- Steel coils are commonly used in construction for various applications such as structural components, including beams, columns, and trusses. They are also used for roofing and cladding systems, as well as in the fabrication of reinforcing bars and precast concrete elements. Additionally, steel coils are utilized in the manufacturing of pipes, tubes, and sheet metal products, serving as a crucial material in the construction industry.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Hot Dipped Galvanized Steel Coils for Roofing Sheet SGCC (DX51D+Z)

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords