Hot Dipped Galvanized of Hesco Wire Mesh Barrier

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 200 set

- Supply Capability:

- 5000 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

Hesco Bastion Barrier

The Hesco Bastion Barrier is a modern gabion for military fortification. It is made of a collapsible wire mesh container and heavy duty fabric liner, and used as a temporary blast or small-arms barrier. One of the less heralded life- and labor-saving devices of war.

Originally designed for use on beaches and marshes for erosion and flood control, the Hesco Bastion Barrier quickly became a popular security device. In general, it takes far less labor to build a Hesco Bastion Barrier than an equivalent structure made with sandbags.

Hesco Bastion Barrier

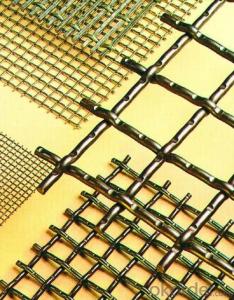

1. Type: Welded mesh

2. Material: Elec-galvanized wire, hot DIP galvanized wire

3. Easy to assemble, firm strength

Hesco Bastion Barrier Typical applications:

Retaining wall structures

River and canal training works

Erosion and scour protection, roadway protection, bridge protection

Hydraulic structures, dams and culverts

Coastal embankment works

Rockfall and soil erosion protection

Pls feel free to contact us for the more information.

sizes of gabion | amount of diaphragm | Standard of gabion | spiral spindle | ||||||||||

| L*W*H(cm) | 300*100 | 300*50 | 200*100 | 200*50 | 150*100 | 150*50 | 100*100 | 100*50 | 50*50 | 150 | 100 | 50 | |

| 300 x 100 x100 | 0 | 4 | 2 | 8 | 8 | ||||||||

| 2 | 4 | 4 | 8 | 16 | 4 | ||||||||

| 300 x 100 x50 | 0 | 2 | 2 | 2 | 8 | 4 | 4 | ||||||

| 2 | 2 | 2 | 4 | 8 | 8 | 8 | |||||||

| 300 x 50 x100 | 0 | 2 | 2 | 2 | 8 | 4 | 4 | ||||||

| 2 | 2 | 2 | 4 | 8 | 8 | 8 | |||||||

| 300 x 50 x50 | 0 | 4 | 2 | 8 | 16 | ||||||||

| 2 | 4 | 4 | 8 | 8 | |||||||||

| 200 x 100 x100 | 0 | 4 | 2 | 16 | |||||||||

| 1 | 4 | 3 | 20 | ||||||||||

| 200 x 100 x50 | 0 | 2 | 2 | 2 | 12 | 4 | |||||||

| 1 | 2 | 2 | 3 | 14 | 6 | ||||||||

- Q:Screen printing and screen printing plate on the photosensitive material What are the requirements

- Printing equipment is simple, the operation will be printed, the plate is simple and the low cost of adaptability strong Chinese printing applications wide range of prints: color oil painting,

- Q:What is the screen printing plate?

- wire mesh Stretched into the box after the screen called, was translucent, flexibility and toughness is very strong.

- Q:Is the screen printing the best way? And other printing methods than it?

- Mass production, and is flat printing can be considered to contact gravure printing, but the plate cost is high

- Q:How to make screen printing layout smooth

- You use the water-based screen version, or oily screen version. Oily general mesh is more dense. Sensitive plastic easy to have static electricity. So the glue can not play too thick. The choice of sensitive adhesive is also important,

- Q:What are the characteristics of screen printing?

- Screen printing generally has the following characteristics: not subject to printing the size and shape of the restrictions, the layout of the soft pressure small

- Q:How to clean the screen plate

- greatly reducing the liquid consumption and cost, operating time Greatly reduced, the operating staff do not touch the liquid, will not hurt the human body.

- Q:What is the principle of screen printing?

- Screen printing is the need to print the text / image through the sensor in the silk (now chemical fiber, mainly polyester fiber) online screen.

- Q:The difference between screen printing characteristics

- But also in the ultra-small, ultra-high precision items on the printing, and can also be printed on the surface or spherical, this printing method has great flexibility and wide applicability.

- Q:What is the commonly used mapping software for screen printing?

- Screen printing commonly used mapping software can be used CorelDRAW, is a special vector graphics production software.

- Q:Screen printing and other printing methods of the difference

- Ink variety, can print a variety of special effects, three-dimensional sense of strong. The printing method is infinitely changing.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Hot Dipped Galvanized of Hesco Wire Mesh Barrier

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 200 set

- Supply Capability:

- 5000 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords