Hot Dipped Galvanized Iron Wire

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

galvanized wire

wire gauge:8--22#(other speccification can be made as customer's request).

type:electro galvanized wire and hot dipped galvanized wire.

material:Q195 Q235.SAE 1006/1008 ECT.

packing: 1--1000kg /coil (as customer's request).

application:this kind of wire is extensively used in construction binding wire woven mesh wire express way fencing mesh wire ect.

Galvanized wire's first stage is drawing.

there are two kinds of drawing machine: powder drawing and water drawing. powder drawing is fit for junior drawing(6.5mm~4.0mm). One powder drawing machine has 4 tanks and 4 molds. One tank is matched with a mold. Each of them are offered energy by a electromotor. 0.9mm(max)can be "eat" when the wire cross a mold. There are no loss of weight during drawing.

Galvanized wire's second stage is anneal.

Anneal is to low the tensile strength of wire. The stove is solid and built with red bricks. The architecture of anneal stove is cuboid. Different thickness of wire require different temperature. Range is from 700°C to 900°C. Output of the anneal stove, the tensile strength is 400N~600N.

Galvanized wire's third stage is chlorhydric acid washing.

After the draw and anneal, the wire is thinner, softer but also much more dirty. It needs chlorhydric acid washing to remove the impurities. Chlorhydric acid washing requires water pool and chlorhydric acid pool. The density of chlorhydric acid is 17%. In the Chlorhydric acid pool, there is a caldron used for the emission of vapor.

Galvanized wire's fourth stage: Zinc coating

After the chlorhydric acid pool, water pool is also necessary.

- Q:Construction in the wall and the beam at the junction of nail wire mesh what role

- Acceleration of heat dissipation, because the thermal conductivity of iron is relatively strong, so the ground heat evenly.

- Q:How does proe draw wire mesh?

- this curve you can draw their own equation can also be used to generate, I used here instead of sine curve example, sketched out a curve ,

- Q:How does the "jagged" on the back of the knife cut the barbed wire?

- Army knife sawtooth is mainly to eliminate the internal strength of the knife body, processing to be quenched, there are jagged, quenching time to eliminate the knife's internal stress, is more solid knife body, and in special times as a saw, do not have to cut wire mesh,

- Q:What is the use of wire

- Or humidity in the case of a week or so generally will rust.However, light and water will not make iron rust, only when the air in the dissolved oxygen in the water, the oxygen in the water environment and

- Q:Is the warm tube laid on top of the steel wire or below?

- and that the road is broken, then the loop must be replaced by all the warm pipe, which means that your room layout of the road to warm all the area to all Out of all to replace the new pipe to replace.

- Q:What is the barbed wire fence? What is the general specification?

- It is drawn from the wire rod into a thin wire (cold wire), and then through a large welding machine will wire welding (that is, we commonly known as wire mesh).

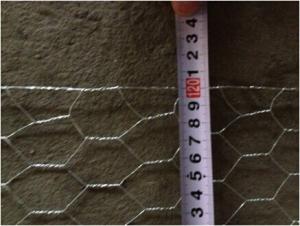

- Q:Barbed wire mesh 20 mesh and 30 mesh what is the difference

- The number of points refers to the length of an inch within the number of cells, then the 20-finger is an inch length of 20 cells, 30 mesh is an inch length of 30 cells, the same length of this contrast is that

- Q:Wire mesh for wire mesh applications

- In the era of peace, barbed wire is not only widely used in machinery, electronics, pharmaceutical, petrochemical, glass, food drying, plastics, paper and chemical fiber, picture tube and other industries, and barbed wire is also widely used in agriculture and life in all aspects.

- Q:In the chemical experiment, how does the wire mesh use? What are the effects?

- Increase the contact area. So that the reaction of iron to participate more intense (fast)

- Q:What is the effect of the wire mesh on the floor

- to speed up the heat: because the thermal conductivity of iron is relatively strong so that the ground is very uniform heat.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Hot Dipped Galvanized Iron Wire

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords