Hot Dipped Galvanized Drywall / Surface Regular Spangle

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications

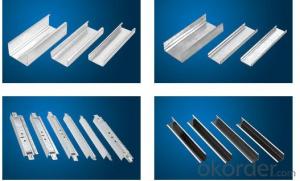

Drywall studs and tracks

Metal studs and tracks

Galvanized steel c profiles

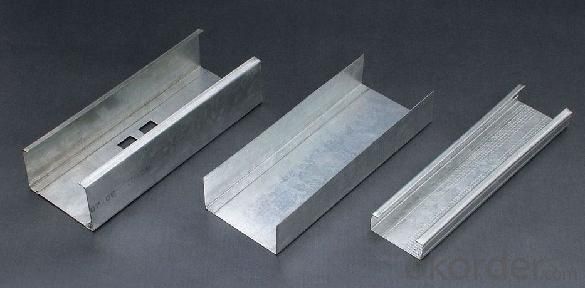

Hot dipped zinc galvanized.

Surface regular spangle

Easy to fix up

All kinds of types

Good rust-Proof function

Drywall Stud & Track and Furring Channel /c channel metal stud

Drywall Stud and Channel, for Ceiling Suspension and Partition Wall System.

Drywall Stud and Channel

Metal Profile, Drywall Stud and Track

Regular Specification for Ceiling Suspension System:

DU38 38*12*3000/6000*0.8 / 1.0mm

DU50 50*15*3000/6000*1.0 / 1.2mm

DU60 60*27*3000/6000*1.2mm

DC50 50*15*3000/6000*0.38 / 0.45mm

50*19*3000/6000*0.38 / 0.45 / 0.5mm

DC60 60*27*3000/6000*0.6mm

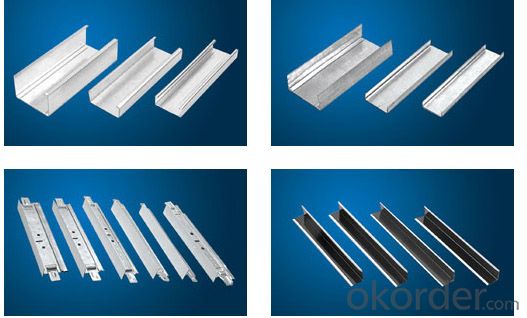

Regular Specification for Partition Wall System:

QC75 75*35*3000/6000*0.5/ 0.6 / 0.7mm

75*40*3000/6000*0.6mm

75*45*3000/6000*0.6 / 0.7mm

75*50*3000/6000*0.6mm

QC100 100*45*3000/6000*0.7mm

100*50*3000/6000*0.7mm

QU75 75*35*3000/6000*0.5 / 0.6 / 0.7mm

75*40*3000*6000*0.6mm

QU100 100*35*3000/6000*0.7mm

100*40*3000/6000*0.7mm

Application

1. used for the permanent constructional structure such as embankment, harbors, docks, retaining walls, anti-earthquake reinforcement project, flood gates, etc

2. used for the provisional structure to seal the mountain, provisionally to retain the wall, to cut off the river, to cofferdam, to lay the pipeline and to ward off the earth, the water or the sand

3. used for the flood-fighting and emergency rescues to prevent the flood, collapse, sink or sediment flow, etc.

- Q:What are the quality control measures for steel coils?

- Quality control measures for steel coils typically include various inspections and tests to ensure that the coils meet the required standards and specifications. These measures often involve visual inspections to identify any surface defects or irregularities, such as cracks, dents, or scratches. Additionally, dimensional checks are performed to verify the coil's size, shape, and weight. Other quality control measures may involve conducting mechanical tests, such as tensile strength and hardness tests, to assess the strength and durability of the steel coils. Overall, these measures aim to guarantee that the steel coils are of high quality and suitable for their intended applications.

- Q:How are steel coils used in the manufacturing of exhaust systems?

- Steel coils are used in the manufacturing of exhaust systems as they are rolled into sheets and then formed into various components such as mufflers, pipes, and catalytic converters. These coils provide the necessary strength, durability, and corrosion resistance required for exhaust system components to withstand high temperatures and harsh conditions.

- Q:If steel can rust with saltwater... then why are ships made of steel? can't we just use other metals like aluminium etc?

- Ships are made of steel and also aluminum. Some minesweepers are made from fiberglass. Steel is a comparatively cheap and easily used material. But don't be confused with the type of steel that is used. Plates do not have to be replaced every year. In fact ship s can go for years with no major steel work, and this can be extended with proper maintenance like sand blasting and painting. There are many different steel alloys with different properties. Some of them resist rusting and instead of flaking they just form a powder like barrier. Check out this link.

- Q:What types of steel are used in steel coils?

- There are various types of steel that are commonly used in steel coils, including carbon steel, stainless steel, and alloy steel.

- Q:Will a 8mm steel ball fired from a 150lbs crossbow kill small game and if so, from how many yards?

- Despite what Billy Goat says there are Crossbows that fire both Ball bearing and bolts. As for any chance of hitting your target living or paper with and degree of accuracy I doubt your chances. Especially small game. Stick to using quarrels/bolts!

- Q:So I was thinking about doing corset waist training and I wanted to know where I can get a real steel boned corset?

- Hi, okorder / There are 3 types of corsets: Fashion corsets, Authentic corsets and Waist training corsets. The fashion corsets are designed for light enclasping of body. They are made with plastics bones usually. The authentic corsets can reduce your waist size about 4 - 5 and the waist training corsets about 6. They both are made with steel spirals and flat bones. The waist training corsets are recommended for experienced wearers only. Look on info pages of the seller. The corsets reinforced with plastic bones are cheap with low durability.

- Q:How do steel coils contribute to seismic resistance in structures?

- Steel coils contribute to seismic resistance in structures by providing strength and flexibility. When placed strategically within the structure, steel coils can absorb and dissipate the energy generated during an earthquake, reducing the impact on the overall structure. This makes the structure more resistant to seismic forces, preventing or minimizing damage that could occur during an earthquake.

- Q:How are steel coils coated for specific applications?

- Steel coils are coated for specific applications through a process called coil coating. This involves applying a protective layer of paint, polymer, or other coatings onto the steel coils using methods like roll coating or spray coating. The coating is carefully selected based on the desired properties such as corrosion resistance, durability, or aesthetic appeal required for the specific application.

- Q:How are steel coils used in the production of steel clamps?

- Steel coils are used in the production of steel clamps as they serve as the main raw material for creating the clamps. The steel coils are first processed and transformed into the desired shape and size through cutting, bending, and shaping processes. These coils are then formed into the clamp's body, providing the necessary strength and durability. Overall, steel coils play a crucial role in manufacturing steel clamps by providing the essential material for their construction.

- Q:How are steel coils cut and shaped for specific requirements?

- Steel coils are cut and shaped for specific requirements through a process called slitting and forming. Slitting involves unwinding the coil and passing it through a set of circular blades that cut it into narrower strips. These strips can then be further processed through different forming techniques such as roll forming, stamping, or bending to achieve the desired shape and dimensions. This allows manufacturers to customize steel coils according to specific requirements for various applications in industries like automotive, construction, and manufacturing.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Hot Dipped Galvanized Drywall / Surface Regular Spangle

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords