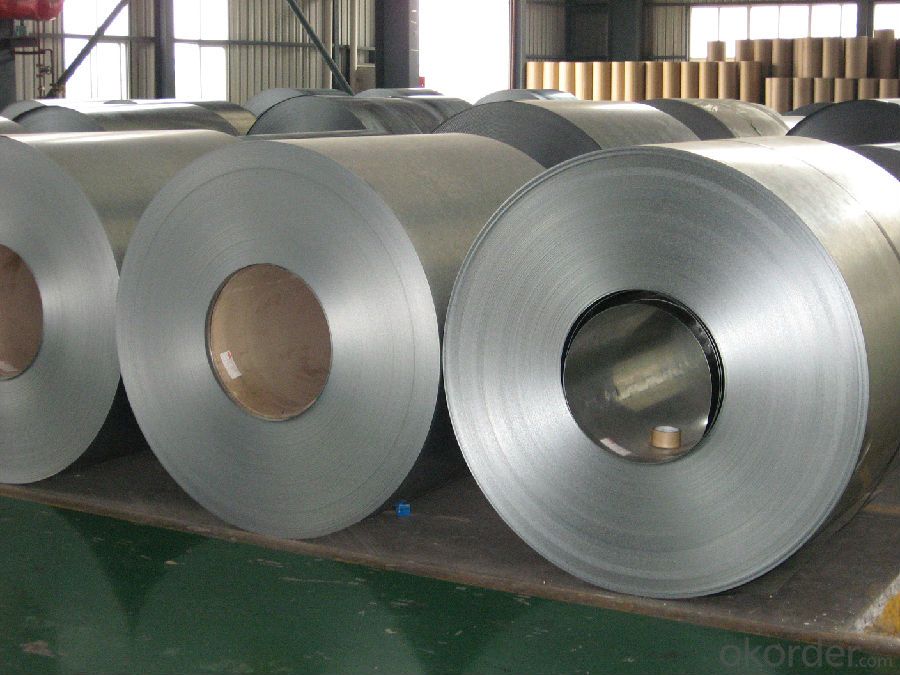

Hot Dipped Galvanized/Aluzinc Steel Coil

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 9000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description

Commodity: Hot dipped galvanized steel coil

Size: Thickness: 0.20mm to 1.2mm; Width: 500mm to 820mm

Surface finish: Regular spangle; Small spangle

Surface treatment: Chromated passivation

Zinc coating: Z08, Z12, Z18

Packing: Mill's standard packing for exporting

Usage: used in the industries such as construction ,cold rolling forming and electro mechanics manufacturing, household electric appliance manufacturing and etc

Standard adopted: GB/T2518-1998;Also we supply such steel strips according to JIS,ASTM standard to meet users'requirements.

Steel grade: Q195,Q195L,SPCC(Other material require agreement )

Equivalent standard: JIS G3302 1998 or ASTM A653M/A924M 1998

Price Terms: FOB, CIF Term

Payment Terms: T/T, L/C at sight

Delivery: 15 days after receiving your valid L/C/down payment

| andard | EN 10142 EN 10147 | DX51D+Z, DX52D+Z, DX53D+Z SS250GD+Z, SS350GD+Z |

| JIS G3321 | SGCC, SGCD, SGCDD, SGC400 | |

| ASTM A792M | CS type C, CS type B, DS, SS250 | |

| Base Metal | Cold rolled steel coils SPCC, SPCD, SPCE, DC01, DC03, DC04, CS, DS, DDS, Q195, Q250, Q350 | |

| Thickness | 0.14mm-3.0mm | |

| Width | 600mm-1600mm | |

| Coil ID | 508mm, 610mm | |

| Zinc coating | 60g/m2-450g/m2 | |

| Surface treating | chromium free passivation, chromium passivation, fingerprint resistant, oiled | |

| Spangle types | Minimal spangle, zero spangle, regular and big spangle | |

- Q:Can steel coils be used in structural applications?

- Yes, steel coils can be used in structural applications. Steel coils are often processed into various shapes and forms, such as beams, columns, or plates, to provide structural support and strength in construction projects. The use of steel coils ensures durability, load-bearing capacity, and resistance to deformation, making them suitable for structural applications in buildings, bridges, and other infrastructure projects.

- Q:The knife will be large and thick. Like the Bowie knife Rambo uses in Rambo III. It doesn't need to be flexible or to hold the edge very well. But i need it to be exceptionally strong material and to stop corrosion at least decently. Is Damascus Steel good?Thank you, in advance.

- Damascus steel is the poorest quality. The laminations separate under stress. Centuries ago the only way to get steel bars was to make it up by hammering wires together in a series of welds. The welds usually were porous and the steel would fail. The pattern of the welds is attractive to some people. An old file has good hard steel and wiill make up into a knife if it is annealed to make it easier to shape and cut. The hardness can be restored by tempering. Treating with oil is the cure to prevent rust.

- Q:How are steel coils used in the manufacturing of transmission systems?

- Steel coils are used in the manufacturing of transmission systems to create various components such as gears, shafts, and bearings. The coils are typically shaped, cut, and machined to form these parts, which are then assembled to create the transmission system. The use of steel coils ensures that the components are strong, durable, and capable of withstanding the high loads and stresses experienced in transmission systems.

- Q:What are the different types of surface defects in steel coils?

- Some of the different types of surface defects in steel coils include scratches, pits, rust, scale, stains, and indentations.

- Q:Several reading methods of steel tape measure

- Direct reading method when measuring the steel tape zero scale alignment measurement starting point, proper tension (stretching force with steel tape tension or tension on the calibration ruler identification shall prevail, with the spring balance measure), direct reading measurement end point corresponding to the scale scale.

- Q:We all know that when we drop a small steel ball (size 3mm diameter; weight 1.10 grams) and a paper (size 11.7 inches length and 8.3 inches breadth; weight 4.5 grams) from a height. The steel ball will win the race to the ground due to its aerodynamic structure.Now imagine the same steel ball with the same weight converted to the structure similar that of paper. What will be the result? Which object will fall first; steel sheet or paper?

- In okorder /... 11.7x8.3 inch paper 97.11 square inches 0.062651488 sq meters at 4.5gm is a non-standard 19 pound bond ledger paper, but that is OK, because at least it is in range. 38 gauge steel sheets are about the thinnest that hold their structure 0.00625 thick 1221 g/m? or, at 11.7x8.3 76.5grams So, with this data at hand we can better visualize the situation. Paper of 0.00625 thick in the size shown is 35# paper 131.68 g/m? 8.25grams Steel is higher in density than paper, so you cannot get the same size and air flow without it being lighter in weight than the steel and the air resistance would be lower for the heavier item, so steel of the same shape and thickness as paper falls faster. Suppose you want paper heavier than steel for the same area, then the thickness increases. Will a steel sheet 0.00625 thick and 11.7x8.3 inch size 76.5gm fall faster or slower than a 9 or 10 times thicker paper sheet? If it was able to hold flat in each type the thicker paper should get more backflow behind it aerodynamically and fall faster than an equal weight thinner steel sheet as my guess, but I don't have those numbers. The steel will always be heavier than the paper for the same exact shape and thickness by about 9x. My answer here is difficult, but the question has some flaws to think about.

- Q:How are steel coils used in the production of furniture components?

- Steel coils are commonly used in the production of furniture components due to their strength, durability, and versatility. These coils, which are made from high-quality steel, are first uncoiled and then fed into a machine called a stamping press. The stamping press uses a die to shape and cut the steel coil into various components required for furniture production, such as chair frames, table legs, or brackets. The use of steel coils allows for the mass production of furniture components with consistent dimensions and high precision. The strength of steel ensures that the components can withstand heavy loads and provide stability to the furniture. Additionally, steel coils can be easily formed into different shapes and sizes, enabling the production of a wide variety of furniture designs. Moreover, steel coils are often coated or treated with protective layers such as paints or galvanization to enhance their resistance to corrosion, moisture, and wear. This ensures that the furniture components have a longer lifespan and maintain their aesthetic appeal over time. In summary, steel coils play a crucial role in the production of furniture components by providing strength, durability, and versatility. They enable the mass production of precise and consistent components, and their protective coatings ensure the longevity and quality of the final furniture products.

- Q:How do steel coils differ in terms of size and weight?

- Steel coils can differ in terms of size and weight based on the specific requirements and applications. The size of steel coils can vary depending on the industry and intended use, ranging from small coils weighing a few hundred kilograms to larger coils weighing several metric tons. The weight of steel coils is primarily determined by the thickness, width, and length of the coil, with thicker and wider coils generally being heavier. Therefore, the variation in size and weight of steel coils is based on the specific needs of different industries and applications.

- Q:How are steel coils inspected for yield strength?

- Steel coils are inspected for yield strength through a series of testing methods. The most common and widely used method is the tensile test. In this test, a small sample is taken from the steel coil and subjected to a controlled load until it reaches its yield point. During the tensile test, the sample is gradually stretched until it deforms and ultimately breaks. The load and elongation data are continuously recorded during this process. The yield strength is then determined by identifying the point on the stress-strain curve where the material begins to exhibit plastic deformation or permanent elongation. Another method used to inspect steel coils for yield strength is the hardness test. Hardness is often correlated with yield strength, and therefore, a hardness test can provide an estimation of the material's yield strength. This test involves measuring the resistance of the steel coil's surface to indentation or penetration using instruments like a Rockwell or Brinell hardness tester. Additionally, non-destructive testing methods such as ultrasonic testing and magnetic particle inspection can also be employed to evaluate yield strength. Ultrasonic testing involves the use of high-frequency sound waves to detect any internal defects or inconsistencies in the material's structure. Magnetic particle inspection, on the other hand, relies on the application of magnetic fields and the use of magnetic particles to identify surface cracks or defects. Overall, various testing methods are available to inspect steel coils for yield strength. These methods provide manufacturers and inspectors with valuable information about the quality and performance capabilities of the steel, ensuring that it meets the required standards and specifications.

- Q:Having a greater amount than 2% carbon in steel causes steel to suddenly become brittle. Why is this?

- Carbon fiber has better tensile capability then steel meaning its better while pulled aside. Plus you could mould the fiber to make autos-or homes-out of carbon fiber.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Hot Dipped Galvanized/Aluzinc Steel Coil

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 9000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords