Hot-dip Zinc Coating Steel Building Roof Walls

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 1212123 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Structure of Hot-Dip Galvanized Steel Sheet Description:

Hot-dip galvanized steel coils are available with a pure zinc coating through the hot-dip galvanizing process. It offers the economy, strength and formability of steel combined with the corrosion resistance of zinc. The hot-dip process is the process by which steel gets coated in layers of zinc to protect against rust. It is especially useful for countless outdoor and industrial applications. Production of cold formed corrugated sheets and profiles for roofing, cladding, decking, tiles, sandwich walls, rainwater protective systems, air conditioning duct as well as electrical appliances and engineering.

2.Main Features of the Hot-Dip Galvanized Steel Sheet:

• Excellent process capability

• Smooth and flat surface

• Workability, durability

• Excellent anticorrosive property

• High strength

• Good formability

• Good visual effect

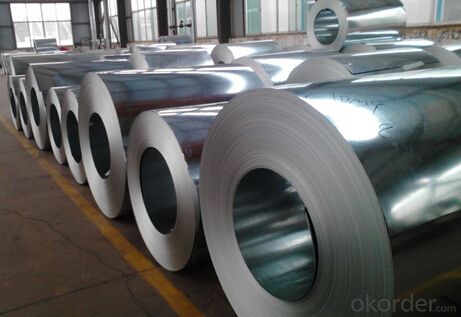

3.Hot-Dip Galvanized Steel Sheet Images

2.Hot-Dip Galvanized Steel Sheet Specification

Standard: ASTM, JIS,EN

Grade: CS, DX51D+Z,SGCC, SS 230~550,S220GD+Z~S550GD+Z, SGC340~SGC570

Thickness: 0.1mm~5mm

Width: max 2000mm

Coil weight:3-12 MT

Coil ID:508/610mm

Surface structure: zero spangle, regular spangle or minimum spangle

Surface treatment: Chromate treatment, Oiled/dry, skinpassed/non-skinpassed

Packing: Standard seaworthy export package

Technology test results:

Processability | Yield strength | Tensile strength | Elongation % | 180°cold-bending |

Common PV | - | 270-500 | - | d=0,intact,no zinc removal |

Mechanical interlocking JY | - | 270-500 | - | d=0,intact,no zinc removal |

Structure JG | >=240 | >=370 | >=18 | d=0,intact,no zinc removal |

Deep drawn SC | - | 270-380 | >=30 | d=0,intact,no zinc removal |

EDDQ SC | - | 270-380 | >=30 | d=0,intact,no zinc removal |

5.FAQ of Hot-Dip Galvanized Steel Sheet

We have organized several common questions for our clients,may help you sincerely:

1.How about your company?

A world class manufacturer & supplier of castings forging in carbon steel and alloy steel,is one of the large-scale professional investment casting production bases in China,consisting of both casting foundry forging and machining factory. Annually more than 8000 tons Precision casting and forging parts are exported to markets in Europe,America and Japan. OEM casting and forging service available according to customer’s requirements.

2.How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

3. How long can we receive the product after purchase?

Usually within thirty working days after receiving buyer’s advance payment or LC. We will arrange the factory manufacturing as soon as possible. The cargo readiness usually takes 15-30 days, but the shipment will depend on the vessel situation.

- Q:How are steel coils welded together?

- Different methods can be employed to weld steel coils together, depending on the specific requirements and the type of steel being used. Electric resistance welding (ERW) is a common method where an electric current is utilized to generate heat in the coils, melting their edges. Pressure is then applied to join them together. ERW is a cost-effective and speedy technique for welding steel coils. Thinner steel coils are often welded using high-frequency induction welding (HFIW). This involves the use of an induction coil to produce an alternating magnetic field, inducing an electric current in the coils. The resistance of the coils to this current generates heat, causing the edges to melt and form a weld. For thicker and heavier steel coils, submerged arc welding (SAW) is commonly employed. This technique utilizes a granular flux and a continuous electrode that is fed into the weld area. The flux melts, creating a protective shield for the weld pool, while the electrode melts to form the weld. SAW is a robust and efficient method for welding steel coils. In addition to these methods, laser welding and gas metal arc welding (GMAW) can also be utilized for welding steel coils. Laser welding offers high precision and speed, while GMAW, also known as MIG welding, utilizes an electric arc between a consumable wire electrode and the steel coils to create a weld. Irrespective of the welding method employed, successful welding of steel coils hinges on proper edge preparation, maintenance of appropriate heat and pressure levels, and the use of correct welding techniques.

- Q:What are the dimensions of steel coils used in the HVAC industry?

- Different applications and system requirements in the HVAC industry can lead to varying dimensions for steel coils. However, there are commonly used standard dimensions. A typical width for steel coils in HVAC systems is approximately 24 inches or 2 feet. This width promotes efficient airflow and heat transfer within the system. The thickness of the steel coils can also vary, but it usually falls within the range of 0.020 inches to 0.060 inches. Thicker coils may be utilized for heavy-duty applications or systems demanding higher performance, while thinner coils are suitable for lighter-duty or cost-effective systems. The length of the coils can also vary based on the specific HVAC system requirements. Although coils are often manufactured in standard lengths like 50 or 100 feet, customization is possible to meet unique needs. It is essential to recognize that these dimensions serve as general guidelines and may differ depending on the manufacturer, supplier, and specific HVAC system requirements. Seeking advice from industry professionals or manufacturers can offer more precise information on the dimensions of steel coils for a particular HVAC system.

- Q:My 8-year-old and 9-year-old boys have approached me with an interesting question. Does fire burn steel? One says yes, the other says no. Help me to settle yet another debate :)

- Fire doesn't burn steel, fire is the catalyst for steel to react with oxygen and burn though technically it's oxidizing. An intense flame like that found in an Oxy-Acetylene torch will bring the steel to melting point, then the operator would toggle a lever on the torch blasting pure oxygen into the steel causing it to oxidize and fall away from the workpiece. The afore mentioned steel wool exercise illustrates the principle on metal so thin that the heat provided by a candle allows for oxidization with the oxygen present in the atmosphere.

- Q:How are steel coils used in the manufacturing of suspension springs?

- Steel coils are used in the manufacturing of suspension springs as they are wound into a specific shape and size to provide the necessary flexibility and resilience required to absorb shocks and vibrations in a vehicle's suspension system. The coils are designed to support the weight of the vehicle and provide a smooth and comfortable ride by compressing and expanding as the vehicle moves over uneven surfaces.

- Q:What is the (balanced) chemical equation for steel?

- I hate to differ but I must. Steel is a mixture of iron and carbon but the carbon content ranges from a small fraction of a percent to no more than 2%. Stainless steel is an alloy of Iron and up to 15% or so of other metals but since there are several types and many varieties in each type it's hardly worth getting into. A good common hardenable high-carbon spring steel is AISI 1095. In this code the 95 refers to 0.95% carbon. When the carbon level goes up to 1.5% to 2% the steel is very brittle and black with the highest carbon steel being pretty much pig-iron.

- Q:What is the weight of a standard steel coil?

- The weight of a standard steel coil can vary depending on its size and thickness. However, a typical range for a standard steel coil is between 5,000 to 10,000 pounds (2,268 to 4,536 kilograms).

- Q:How are steel coils used in the production of agricultural storage tanks?

- Steel coils are used in the production of agricultural storage tanks as they serve as the primary material for constructing the tank walls and base. The coils are shaped and welded together to form a sturdy and durable structure that can withstand the weight and pressure of storing agricultural products such as grains, feed, and fertilizers. The steel coils provide the necessary strength and corrosion resistance required for long-term storage in various agricultural environments.

- Q:What are the challenges in coil blanking for complex shapes?

- In order to achieve accurate and efficient results, there are several challenges that need to be addressed when it comes to coil blanking for complex shapes. One of the main challenges lies in the precise positioning and alignment of the coil material. When dealing with complex shapes, intricate cutting patterns are often required, and any misalignment or deviation can result in inaccurate cuts and wasted material. Another challenge involves the selection and optimization of the blanking tooling. Specialized dies and punches are often necessary for complex shapes, and these need to be carefully designed and manufactured to ensure accuracy and consistency. This not only involves choosing the right tooling materials but also considering factors such as cutting forces, wear resistance, and tool life. The complexity of the shapes also presents challenges in terms of material deformation and springback. During the blanking process, the material undergoes various deformations and stresses, which can cause distortions and dimensional variations in the final product. Achieving the desired shape while minimizing these deformations requires a deep understanding of material properties and advanced techniques like compensation and adjustment in the die design. Furthermore, the high-speed nature of coil blanking for complex shapes can result in increased vibration and noise levels. The dynamic forces involved in cutting intricate shapes can lead to tool chatter and excessive noise, affecting both the quality of the cut and overall operational efficiency. It is vital to implement effective damping and vibration control measures, such as tool coatings and optimized cutting parameters, to address these challenges. Lastly, the complexity of the shapes can impact production efficiency. Complex shapes often require longer tool setup times and more frequent tool changes, leading to increased downtime and reduced productivity. Additionally, the intricate nature of the cuts may require multiple passes or additional machining operations, further adding to the production time and complexity. To overcome these challenges, manufacturers need to invest in advanced technologies like computer-aided design and simulation software to optimize the blanking process. Continuous research and development efforts focused on improving tooling materials, cutting techniques, and process control can also help address the challenges associated with coil blanking for complex shapes.

- Q:What are the industries that consume the most steel?

- I'm guessing manufacturing

- Q:What are the different surface treatments for steel coils?

- Steel coils can undergo various surface treatments to achieve different outcomes and applications. Some commonly used treatments include: 1. Hot-dip galvanizing: Steel coils are immersed in molten zinc, which forms a protective layer on the surface. This treatment provides excellent corrosion resistance for outdoor use. 2. Electro-galvanizing: A thin layer of zinc is electroplated onto the steel coils. It offers good corrosion resistance and is suitable for indoor applications. 3. Powder coating: Dry powder is applied to the surface and heated to form a durable coating. It provides excellent corrosion resistance and comes in different colors and finishes. 4. Paint coating: Steel coils can be coated with liquid paint, offering both corrosion resistance and aesthetic appeal. The thickness and finish can be customized according to the desired look and level of protection. 5. Phosphating: Steel coils are immersed in a phosphate solution, creating a thin layer that enhances paint adhesion and improves corrosion resistance. 6. Chromate conversion coating: Steel coils are immersed in a solution containing chromium salts, providing excellent corrosion resistance and acting as a primer for subsequent paint or powder coating. 7. Zinc-nickel plating: A layer of zinc-nickel alloy is electroplated onto the steel coils, offering superior corrosion resistance compared to pure zinc plating and is suitable for demanding environments. These are just a few examples of the many available surface treatments for steel coils. The choice depends on factors such as application, desired corrosion resistance, aesthetic requirements, and budget. It is important to carefully consider project needs and consult with experts to determine the most suitable treatment.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Hot-dip Zinc Coating Steel Building Roof Walls

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 1212123 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords