Hot-Dip Gavalnized Steel Sheet in High Quality

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Hot-dip Zinc Coating Steel Building Roof Walls

1.Structure of Hot-Dip Galvanized Steel Sheet Description:

Hot-dip galvanized steel coils are available with a pure zinc coating through the hot-dip galvanizing process. It offers the economy, strength and formability of steel combined with the corrosion resistance of zinc. The hot-dip process is the process by which steel gets coated in layers of zinc to protect against rust. It is especially useful for countless outdoor and industrial applications. Production of cold formed corrugated sheets and profiles for roofing, cladding, decking, tiles, sandwich walls, rainwater protective systems, air conditioning duct as well as electrical appliances and engineering.

2.Main Features of the Hot-Dip Galvanized Steel Sheet:

• Excellent process capability

• Smooth and flat surface

• Workability, durability

• Excellent anticorrosive property

• High strength

• Good formability

• Good visual effect

3.Hot-Dip Galvanized Steel Sheet Images:

4.Hot-Dip Galvanized Steel Sheet Specification

Standard: ASTM, JIS,EN

Grade: CS, DX51D+Z,SGCC, SS 230~550,S220GD+Z~S550GD+Z, SGC340~SGC570

Thickness: 0.1mm~5mm

Width: max 2000mm

Coil weight:3-12 MT

Coil ID:508/610mm

Surface structure: zero spangle, regular spangle or minimum spangle

Surface treatment: Chromate treatment, Oiled/dry, skinpassed/non-skinpassed

Packing: Standard seaworthy export package

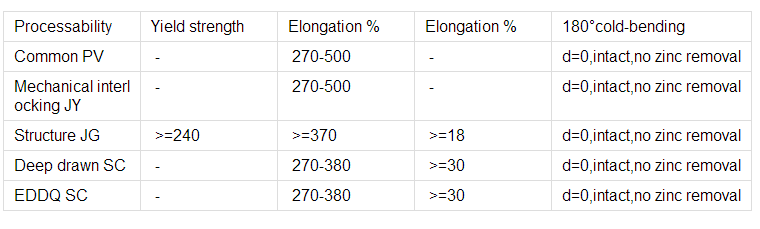

Technology test results:

5.FAQ of Hot-Dip Galvanized Steel Sheet :

We have organized several common questions for our clients,may help you sincerely:

1.How about your company?

A world class manufacturer & supplier of castings forging in carbon steel and alloy steel,is one of the large-scale professional investment casting production bases in China,consisting of both casting foundry forging and machining factory. Annually more than 8000 tons Precision casting and forging parts are exported to markets in Europe,America and Japan. OEM casting and forging service available according to customer’s requirements.

2.How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

3. How long can we receive the product after purchase?

Usually within thirty working days after receiving buyer’s advance payment or LC. We will arrange the factory manufacturing as soon as possible. The cargo readiness usually takes 15-30 days, but the shipment will depend on the vessel situation.

- Q:How are steel coils measured?

- Steel coils are typically measured in terms of their width, thickness, and weight. The width is determined by measuring the distance across the coil's widest point, while the thickness is measured by gauging the thickness of the steel sheet. The weight of the coil is measured by weighing it using scales or load cells.

- Q:How are steel coils used in the manufacturing of electrical appliances?

- Steel coils are used in the manufacturing of electrical appliances primarily for their magnetic properties. These coils are wound around a core to create electromagnets, which are essential components in various appliances like transformers, motors, generators, and solenoids. The magnetic field generated by the steel coils allows for the efficient conversion of electrical energy into mechanical energy or vice versa, enabling the proper functioning of these appliances.

- Q:How are steel coils used in the manufacturing of automotive suspension systems?

- Steel coils are used in the manufacturing of automotive suspension systems as they provide the necessary support and resistance to absorb shocks and vibrations. These coils, also known as coil springs, are typically positioned between the vehicle's frame and the suspension system to enhance stability and ensure a smooth ride.

- Q:Can steel coils be stamped?

- Yes, steel coils can be stamped. Stamping is a common manufacturing process used to shape and cut steel coils into desired forms and designs.

- Q:How are steel coils used in the packaging industry?

- Steel coils are used in the packaging industry primarily for the production of metal strapping and seals. These coils are unwound and processed to create strong and durable strapping materials that are used to secure and bundle various types of packaging, such as boxes, crates, and pallets. The steel coils provide excellent tensile strength and resistance to breakage, making them ideal for ensuring the safe transportation and storage of goods.

- Q:How are steel coils used in the production of wind turbine components?

- Steel coils are an essential component in the production of wind turbine components. These coils are typically made from high-strength steel, which is known for its durability and ability to withstand harsh weather conditions. One of the primary uses of steel coils in wind turbine production is in the manufacturing of the tower. The tower is the structure that supports the entire wind turbine, and it needs to be strong enough to withstand the weight of the nacelle and the rotor blades. Steel coils are used to fabricate the sections of the tower, which are then assembled to create a tall and sturdy structure. Another crucial application of steel coils is in the production of the rotor blades. The rotor blades are responsible for capturing the wind's energy and converting it into rotational motion. Steel coils are used in the manufacturing of the blade's internal structure, known as the spar, which provides strength and rigidity to the blade. The coils are shaped and formed into the desired blade shape, and then composite materials are added to enhance its aerodynamic properties. Furthermore, steel coils are also utilized in the production of other wind turbine components such as the hub and the nacelle. The hub is the central part of the rotor, to which the blades are attached, and it requires a strong and reliable steel structure to sustain the immense forces generated by the rotating blades. The nacelle, on the other hand, houses the generator and other vital components of the wind turbine, and steel coils are used in its construction to ensure stability and protection. In summary, steel coils play a crucial role in the production of wind turbine components. From the tower to the rotor blades, hub, and nacelle, steel coils provide the necessary strength, durability, and stability required to withstand the demanding conditions of wind energy production. Without these coils, the construction and operation of wind turbines would not be possible, as they form the backbone of these renewable energy systems.

- Q:What is the cost of a steel coil?

- The cost of a steel coil can vary depending on several factors such as the type of steel, size, weight, and market conditions. It is best to contact a steel supplier or manufacturer for an accurate and up-to-date price quote.

- Q:How are steel coils used in the manufacturing of electrical wiring?

- Steel coils are used in the manufacturing of electrical wiring as a core material for cable reinforcement. The coils provide structural strength and support to the wires, ensuring durability and resistance to external forces. Additionally, the steel coils help in maintaining proper electrical conductivity and minimize electrical losses, ensuring efficient power transmission and distribution.

- Q:How are steel coils used in the production of oil and gas equipment?

- Steel coils are used in the production of oil and gas equipment as they are typically shaped and welded to create various components such as pipes, tanks, and pressure vessels. These coils provide a strong and durable foundation for the equipment, ensuring it can withstand the harsh conditions and high pressures associated with oil and gas extraction and processing.

- Q:How are steel coils used in the manufacturing of consumer goods?

- Steel coils are used in the manufacturing of consumer goods as a primary material for various applications. They are commonly used in the production of appliances, automotive parts, construction materials, and packaging materials. The coils can be shaped, cut, and formed into different components or structures, providing strength, durability, and versatility to the end products.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Hot-Dip Gavalnized Steel Sheet in High Quality

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords