Hot Dip Galvanized Steel Sheets in High Quality

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Hot-dip Zinc Coating Steel Building Roof Walls

1.Structure of Hot-Dip Galvanized Steel Sheet Description:

Hot-dip galvanized steel coils are available with a pure zinc coating through the hot-dip galvanizing process. It offers the economy, strength and formability of steel combined with the corrosion resistance of zinc. The hot-dip process is the process by which steel gets coated in layers of zinc to protect against rust. It is especially useful for countless outdoor and industrial applications. Production of cold formed corrugated sheets and profiles for roofing, cladding, decking, tiles, sandwich walls, rainwater protective systems, air conditioning duct as well as electrical appliances and engineering.

2.Main Features of the Hot-Dip Galvanized Steel Sheet:

• Excellent process capability

• Smooth and flat surface

• Workability, durability

• Excellent anticorrosive property

• High strength

• Good formability

• Good visual effect

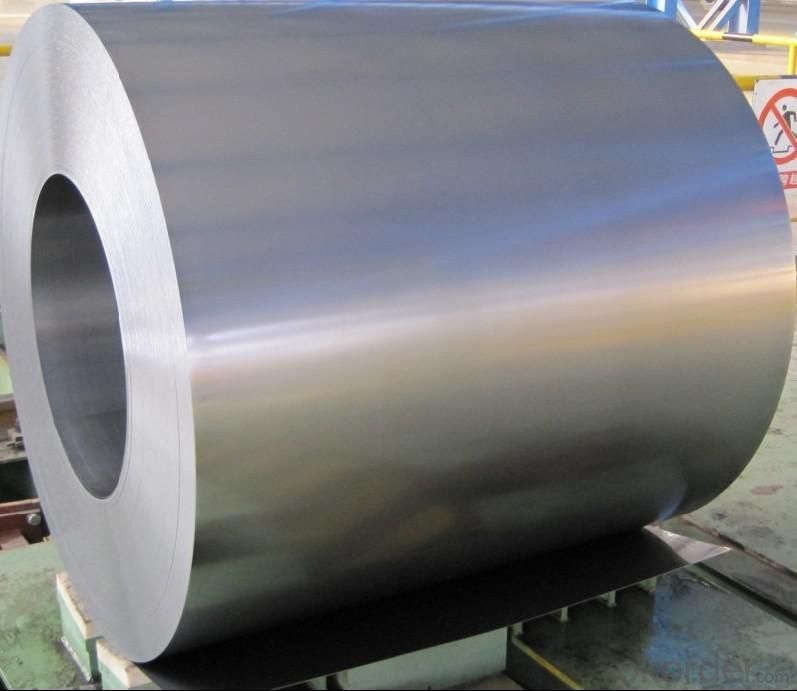

3.Hot-Dip Galvanized Steel Sheet Images:

4.Hot-Dip Galvanized Steel Sheet Specification:

Standard: ASTM, JIS,EN

Grade: CS, DX51D+Z,SGCC, SS 230~550,S220GD+Z~S550GD+Z, SGC340~SGC570

Thickness: 0.1mm~5mm

Width: max 2000mm

Coil weight:3-12 MT

Coil ID:508/610mm

Surface structure: zero spangle, regular spangle or minimum spangle

Surface treatment: Chromate treatment, Oiled/dry, skinpassed/non-skinpassed

Packing: Standard seaworthy export package

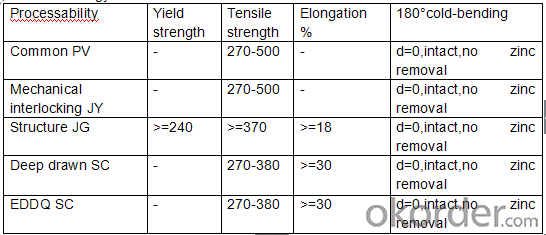

Technology test results:

5.FAQ of Hot-Dip Galvanized Steel Sheet:

We have organized several common questions for our clients,may help you sincerely:

1.How about your company?

A world class manufacturer & supplier of castings forging in carbon steel and alloy steel,is one of the large-scale professional investment casting production bases in China,consisting of both casting foundry forging and machining factory. Annually more than 8000 tons Precision casting and forging parts are exported to markets in Europe,America and Japan. OEM casting and forging service available according to customer’s requirements.

2.How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

3. How long can we receive the product after purchase?

Usually within thirty working days after receiving buyer’s advance payment or LC. We will arrange the factory manufacturing as soon as possible. The cargo readiness usually takes 15-30 days, but the shipment will depend on the vessel situation.

- Q:Can steel sheets be used for manufacturing machinery parts?

- Yes, steel sheets can be used for manufacturing machinery parts. Steel is a strong and durable material that is commonly used in the manufacturing industry for various applications, including machinery parts. Steel sheets can be easily formed, cut, and welded to create complex shapes and structures required for machinery components. Additionally, steel offers excellent mechanical properties such as high tensile strength and resistance to wear, which are crucial for machinery parts that are subjected to heavy loads and frequent use.

- Q:Are steel sheets resistant to impact?

- Yes, steel sheets are generally resistant to impact due to their strong and durable nature.

- Q:Can steel sheets be used in energy applications?

- Yes, steel sheets can be used in energy applications. Steel sheets are commonly used in the construction of power plants, wind turbines, and solar panels due to their high strength, durability, and resistance to extreme temperatures. They are also used in the manufacturing of energy-efficient appliances and energy storage systems.

- Q:How do steel sheets perform in terms of wear resistance?

- In terms of wear resistance, steel sheets exhibit impressive performance. Renowned for their strength and durability, steel is well-known for these attributes, and steel sheets are equally exceptional. They possess the capability to endure substantial loads, abrasion, and impact, rendering them highly suitable for various applications where wear resistance is of utmost importance. Moreover, the wear resistance of steel sheets can be further augmented through the utilization of surface treatments or coatings. In summary, steel sheets are extensively favored in industries necessitating materials capable of enduring wear and tear for prolonged durations.

- Q:Can steel sheets be painted or powder-coated after installation?

- Yes, steel sheets can be painted or powder-coated after installation. Painting or powder-coating steel sheets after installation is a common practice to enhance their aesthetic appeal and provide additional protection against corrosion. The process involves thoroughly cleaning the steel surface, applying a primer to ensure good adhesion, and then applying the desired paint or powder coating. This can be done on-site or in a specialized facility, depending on the size and complexity of the steel sheets. Additionally, it is important to ensure that the chosen paint or powder coating is suitable for exterior use and can withstand the environmental conditions to which the steel sheets will be exposed.

- Q:Stainless steel plate how to cast mirror plate?

- Stainless steel hot rolled plate mirror polishing (mirror, polishing)In recent years, more and more requirements for polishing of stainless steel hot rolled plate, and even mirror polishing have been demanded. The treatment of hot rolled plate is quite different from that of cold rolled plate, and the whole process is more complicated and difficult to handle than cold rolled plate.

- Q:Are steel sheets fire resistant?

- Yes, steel sheets are fire resistant.

- Q:Do steel sheets rust?

- Yes, steel sheets can rust if they are not properly protected or if exposed to moisture and oxygen for extended periods of time.

- Q:Can steel sheets be customized according to specific requirements?

- Yes, steel sheets can be customized according to specific requirements. Steel manufacturers have the capability to produce steel sheets in various sizes, thicknesses, and finishes to meet the specific needs of customers. Customization options also include specific alloy compositions, surface treatments, and mechanical properties. Through cutting, shearing, bending, and shaping processes, steel sheets can be tailored to fit specific dimensions and shapes required for various applications. Additionally, manufacturers can also provide customized branding, labeling, and packaging options as per the customer's requirements. Overall, steel sheets offer a high level of flexibility and can be easily customized to meet specific requirements.

- Q:STCC what's the quality of the cold rolled steel sheet?

- Cold rolled steel: iron sheet thin, generally zero millimeters, galvanized; steel plate thickness, generally more than 3mm, there are also 1mm

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Hot Dip Galvanized Steel Sheets in High Quality

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords