Hot-Dip Galvanized Steel Sheet of Best Quality

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 30 m.t.

- Supply Capability:

- 1000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

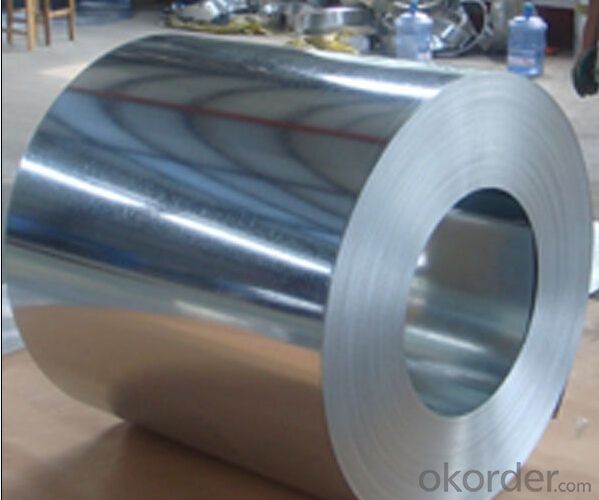

1.Structure of Hot-Dip Galvanized Steel Sheet Description:

Hot-dip galvanized steel coils are available with a pure zinc coating through the hot-dip galvanizing process. It offers the economy, strength and formability of steel combined with the corrosion resistance of zinc. The hot-dip process is the process by which steel gets coated in layers of zinc to protect against rust. It is especially useful for countless outdoor and industrial applications. Production of cold formed corrugated sheets and profiles for roofing, cladding, decking, tiles, sandwich walls, rainwater protective systems, air conditioning duct as well as electrical appliances and engineering.

2.Main Features of the Hot-Dip Galvanized Steel Sheet:

• Galvanized steel frames are used to build houses.

• Car parts are made out of galvanized steel, for example, the body of trucks and buses.

• Galvanized metal has found its way into several household appliances such as washing machines, air conditioning housings, hair dryers, etc.

• It is used in high tension electrical towers, protective gears, highway signs etc.

• It is also used to make wrought iron gates and other items

• Also used to make metal pails.

3.Hot-Dip Galvanized Steel Sheet Images

4.Hot-Dip Galvanized Steel Sheet Specification

Standard: JIS G3302 / ASTM A653M / EN10327 / DIN17162

Grade: SGSS/SGCD1/SGCD2/SGCD3/SGC340,400,440,490,570/CS TypeA,B,C/FS TypeA/FS TypeB/DDS TypeA,C/EDDS/DX51D+Z

Thickness: 0.1mm~5mm

Width: max 2000mm

Coil weight:3-12 MT

Coil ID:508/610mm

Surface structure: zero spangle, regular spangle or minimum spangle

Surface treatment: Chromate treatment, Oiled/dry, skinpassed/non-skinpassed

Packing: Standard seaworthy export package

Technology test results:

5.FAQ of Hot-Dip Galvanized Steel Sheet

We have organized several common questions for our clients,may help you sincerely:

1.How about your company?

A world class manufacturer & supplier of castings forging in carbon steel and alloy steel,is one of the large-scale professional investment casting production bases in China,consisting of both casting foundry forging and machining factory. Annually more than 8000 tons Precision casting and forging parts are exported to markets in Europe,America and Japan. OEM casting and forging service available according to customer’s requirements.

2.How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

3. How long can we receive the product after purchase?

Usually within thirty working days after receiving buyer’s advance payment or LC. We will arrange the factory manufacturing as soon as possible. The cargo readiness usually takes 15-25 days, but the shipment will depend on the vessel situation.

- Q:I have a job where I'm required to wear ANSI certified steel toed boots or shoes(so long as its ANSI). Thing is, I'm a vegan. I do NOT want to buy leather, and I will go to great lengths to buy a non leather shoe/boot I can wear on the job! I AM currently borrowing my dad's leather ANSI boots, but would very much love to be able to rock a pair of cruelty free boots/shoes on the job!It does not have to be certified vegan just all man-made materials and no leather/sued and other such stuff where animals have to die. It would make me no better than the massive slaughterhouse industries and such. Valueing money of ver live/morals. I don't want one of the first things I need to do in my manufacturing job is compromising my morals. :3So if you know of an ANSI vegan friendly boot brand PLEASE TELL ME! *gets on knees begging*Money isn't really an option for me, I'll just continue borrowing my dad's boots till I save up enough!Thanks in advance! :D

- Sears okorder /

- Q:I would like to know if steel is basically a very dense crystal, or if it is a different atomic structure

- Steel Crystalline Structure

- Q:How are steel coils used in the production of shelving units?

- Steel coils are used in the production of shelving units by being processed and formed into various components such as shelves, brackets, and support beams. These coils are typically cut, bent, and welded to create the necessary shapes and sizes required for the shelving unit. The steel material provides strength and durability to the shelves, ensuring they can hold heavy items and withstand the weight placed on them.

- Q:What are the environmental and social impacts of mining, processing and using steel?

- I don't think society as we know it could exist without it. As for the enviroment there is damage from mining, processing and from using steel equiptment.

- Q:How do steel coils contribute to durability and longevity in products?

- The durability and longevity of products are greatly enhanced by steel coils, mainly because of their strength, stability, and resistance to corrosion. Firstly, steel is widely known for its exceptional strength, making it the perfect material for applications where durability is crucial. Steel coils, which are essentially tightly rolled steel, add strength and structural integrity to products. The stability offered by steel coils is another important factor in improving product durability. The tightly rolled structure of the coils ensures that they maintain their shape and resist deformation even under heavy loads or extreme conditions. This stability is particularly significant in industries like construction and automotive, where products need to withstand rigorous usage for long periods of time. Furthermore, steel coils have excellent resistance to corrosion, primarily due to the presence of protective coatings. These coatings, such as zinc or other metallic alloys, act as a barrier against moisture and environmental elements that cause rust and degradation. By preventing corrosion, steel coils help extend the lifespan of products, making them more durable and reliable. Moreover, steel coils can be customized to meet specific requirements, such as different thicknesses, widths, or surface finishes. This versatility allows manufacturers to tailor the steel coils to their desired application, ensuring optimal performance and longevity in their products. To sum up, steel coils contribute to the durability and longevity of products through their strength, stability, corrosion resistance, and customization capabilities. By incorporating steel coils into various industries and applications, manufacturers can ensure that their products last longer and provide greater reliability to consumers.

- Q:In terms of weight to strength titanium is stronger. But is it stronger than mild steel? If it is stronger, how much stronger is it?

- Yes ,i think so. The two most useful properties of the metal form are corrosion resistance, and the highest strength-to-weight ratio of any metal.[4] In its unalloyed condition, titanium is as strong as some steels, but 45% lighter.[5] There are two allotropic forms[6] and five naturally occurring isotopes of this element; 46Ti through 50Ti, with 48Ti being the most abundant (73.8%).[7] Titanium's properties are chemically and physically similar to zirconium.

- Q:What is the maximum length of a steel coil?

- The maximum length of a steel coil can vary depending on various factors such as the type of steel, manufacturing process, and intended use. However, in general, steel coils can range from several hundred feet to several thousand feet in length.

- Q:What are the typical coil width options?

- The typical coil width options vary depending on the industry and application, but common options include 12 inches, 18 inches, 24 inches, and 36 inches.

- Q:What is the maximum width of a steel coil?

- The maximum width of a steel coil can vary depending on the specific manufacturing capabilities and equipment being used. However, in general, steel coils can have widths ranging from a few inches to several feet.

- Q:What are the advantages of using steel coils?

- There are several advantages of using steel coils. Firstly, steel coils are highly durable and have a longer lifespan compared to other materials, making them ideal for long-term use. Additionally, steel coils have excellent strength-to-weight ratio, allowing them to withstand heavy loads without compromising structural integrity. They also provide superior resistance to corrosion, making them suitable for various environments, including high humidity or coastal areas. Furthermore, steel coils can be easily recycled, making them an environmentally friendly choice. Overall, the advantages of using steel coils include durability, strength, corrosion resistance, and sustainability.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Hot-Dip Galvanized Steel Sheet of Best Quality

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 30 m.t.

- Supply Capability:

- 1000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords