Hot-Dip Galvanized Steel Sheet of All Size

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 30 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Structure of Hot-Dip Galvanized Steel Sheet Description:

Hot-dip galvanized steel coils are available with a pure zinc coating through the hot-dip galvanizing process. It offers the economy, strength and formability of steel combined with the corrosion resistance of zinc. The hot-dip process is the process by which steel gets coated in layers of zinc to protect against rust. It is especially useful for countless outdoor and industrial applications. Production of cold formed corrugated sheets and profiles for roofing, cladding, decking, tiles, sandwich walls, rainwater protective systems, air conditioning duct as well as electrical appliances and engineering.

2.Main Features of the Hot-Dip Galvanized Steel Sheet:

• Excellent process capability

• Smooth and flat surface

• Workability, durability

• Excellent anticorrosive property

• High strength

• Good formability

• Good visual effect

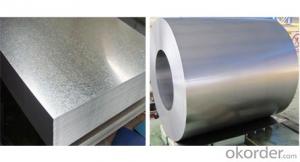

3.Hot-Dip Galvanized Steel Sheet Images

4.Hot-Dip Galvanized Steel Sheet Specification

Q/TB303,EN 10130:DC04,DC03; Q/TB302,JIS G3141 :SPCC,SPCD

EN 10130:DC04; JIS G3141 :SPCE;

Q/TB303-2008:DC01( O3), DC03( O3);

STANDARDS :2010JX(25) :TYH-2; 2010JX(12) :TYH-3; 2010JX(22) :TYH-4;

STANDARDS :GBT11253-2007: Q235; 2011 JX(19):LQ215; 2011 JX(21):THD

STANDARDS : EN10268:2006:HC340LA

STANDARDS : 2010JX(42):TGW800-1, TGW1000A-1, TGW1000B-1

Standard: ASTM, JIS,EN

Grade: CS, DX51D+Z,SGCC, SS 230~550,S220GD+Z~S550GD+Z, SGC340~SGC570

Thickness: 0.1mm~5mm

Width: max 2000mm

Coil weight:3-12 MT

Coil ID:508/610mm

Surface structure: zero spangle, regular spangle or minimum spangle

Surface treatment: Chromate treatment, Oiled/dry, skinpassed/non-skinpassed

Packing: Standard seaworthy export package

Technology test results:

5.FAQ of Hot-Dip Galvanized Steel Sheet

We have organized several common questions for our clients,may help you sincerely:

1.How about your company?

A world class manufacturer & supplier of castings forging in carbon steel and alloy steel,is one of the large-scale professional investment casting production bases in China,consisting of both casting foundry forging and machining factory. Annually more than 8000 tons Precision casting and forging parts are exported to markets in Europe,America and Japan. OEM casting and forging service available according to customer’s requirements.

2.How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

3. How long can we receive the product after purchase?

Usually within thirty working days after receiving buyer’s advance payment or LC. We will arrange the factory manufacturing as soon as possible. The cargo readiness usually takes 15-30 days, but the shipment will depend on the vessel situation.

- Q:How are steel coils welded together?

- Steel coils can be welded together using various methods, depending on the specific requirements and the type of steel being used. One common method is the use of electric resistance welding (ERW), where an electric current is passed through the steel coils to generate heat. This heat melts the edges of the coils, and pressure is applied to join them together. ERW is a quick and cost-effective method for welding steel coils. Another method is high-frequency induction welding (HFIW), which is commonly used for thinner steel coils. In this process, an induction coil is used to generate an alternating magnetic field, which induces an electric current in the steel coils. The resistance of the coils to this electric current generates heat, causing the edges to melt and form a weld. For thicker and heavier steel coils, submerged arc welding (SAW) is often employed. This method involves the use of a granular flux and a continuous electrode, which is fed into the weld area. The flux melts, creating a protective shield for the weld pool, and the electrode melts to form the weld. SAW is a robust and efficient method for welding steel coils. Additionally, laser welding and gas metal arc welding (GMAW) can also be used to weld steel coils. Laser welding offers high precision and speed, while GMAW, also known as MIG welding, uses an electric arc between a consumable wire electrode and the steel coils to create a weld. Regardless of the welding method used, the key factors for successful welding of steel coils are proper preparation of the edges, maintaining the appropriate heat and pressure levels, and ensuring the correct welding technique is employed.

- Q:Can steel coils be used in the production of aerospace components?

- Yes, steel coils can be used in the production of aerospace components. Steel is a durable and versatile material that offers excellent strength-to-weight ratio, making it suitable for various applications in the aerospace industry. Steel coils can be processed and shaped to meet specific requirements, such as forming intricate components, structural parts, or even for use in aerospace engines. Additionally, steel's corrosion resistance properties and ability to withstand high temperatures make it a reliable choice for aerospace applications.

- Q:Maybe it is obvious. But i have thought alot about it.I thought steel at a cool temperature was unbreakable. I am not one for science or physics or engineering (i am a political science major). But i don't understand why the planes that struck the world trade center on 9-11 didn't just dent the side and fall,How did the place break the steel? Was it the velocity? Is steel easily broken?I realized that i wasn't taught how the planes broke the steel, and that no one ever asked. I searched the web and i couldn't find the answer or even anyone who had asked the question before.(i don't care about conspiracy theories, i just want scientific facts)

- The buildings only had steel cores within the infrastructure to support the weight and flexibility - quite normal. You would be right if the whole surface of the building was pure reinforced steel with no openings (i.e. a ridiculous giant 100% purely steel tower). Can you imagine the force of a large jet at very high speed hitting a building, along with carrying vast amounts of highly explosive fuel. You don't need to, you've seen it... The bits of steel may well have been undamaged and collectable at ground zero, while the building was destroyed.

- Q:What are the different types of surface defects in steel coils?

- Some of the different types of surface defects in steel coils include scratches, pits, rust, scale, stains, and indentations.

- Q:How are steel coils processed into finished products?

- Steel coils are processed into finished products through a series of steps including uncoiling, leveling, cutting, shaping, and surface treatment. The uncoiling process involves unwinding the steel coil to create a flat sheet. Next, leveling machines remove any unevenness in the sheet's surface. Then, the sheet is cut into desired lengths or shapes using cutting machines. Shaping processes such as bending, rolling, or stamping are performed to achieve the desired product form. Finally, surface treatment techniques like galvanizing, painting, or coating are applied to enhance the product's durability and appearance.

- Q:How are steel coils tested for flatness and straightness?

- Steel coils are commonly tested for flatness and straightness using various methods such as visual inspection, measuring with straightedges, laser-based measurements, or using specialized equipment like tension leveling machines. These tests ensure that the steel coils meet the required standards and are suitable for further processing or use in various industries.

- Q:I'm looking to get a track bike/ fixie to ride around the city of Chicago. I've looked at many bikes and they're mostly made out of Hi Ten steel. My old fixie (which was stolen at North Ave Beach) was made out of aluminum (KHS FLITE 100). How big of a difference is it between aluminum and steel? I know steel is heavier but how does it effect the ride? Is a aluminum bike or a steel bike better to get to ride around the bike path and in the city of Chicago?

- Depends okorder

- Q:What are the different types of steel coil surface treatment methods?

- There are several different types of steel coil surface treatment methods, including galvanizing, painting, powder coating, and pickling. Galvanizing involves applying a layer of zinc to the steel surface to protect against corrosion. Painting provides a decorative and protective coating by applying a layer of paint. Powder coating involves electrostatically applying a dry powder onto the steel surface, which is then cured to form a durable coating. Pickling is a chemical process that removes impurities and scales from the steel surface, resulting in a clean and smooth finish.

- Q:Can steel coils be coated with barcodes?

- Yes, steel coils can be coated with barcodes.

- Q:What is the average lifespan of a steel coil?

- The average lifespan of a steel coil can vary depending on various factors such as its quality, usage, maintenance, and environmental conditions. However, on average, a well-maintained steel coil can last anywhere from 10 to 30 years.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Hot-Dip Galvanized Steel Sheet of All Size

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 30 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords