Hot-dip Galvanized Steel Sheet/Coil in High Quality

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Hot-dip Zinc Coating Steel Building Roof Walls

1.Structure of Hot-Dip Galvanized Steel Sheet Description:

Hot-dip galvanized steel coils are available with a pure zinc coating through the hot-dip galvanizing process. It offers the economy, strength and formability of steel combined with the corrosion resistance of zinc. The hot-dip process is the process by which steel gets coated in layers of zinc to protect against rust. It is especially useful for countless outdoor and industrial applications. Production of cold formed corrugated sheets and profiles for roofing, cladding, decking, tiles, sandwich walls, rainwater protective systems, air conditioning duct as well as electrical appliances and engineering.

2.Main Features of the Hot-Dip Galvanized Steel Sheet:

• Excellent process capability

• Smooth and flat surface

• Workability, durability

• Excellent anticorrosive property

• High strength

• Good formability

• Good visual effect

3.Hot-Dip Galvanized Steel Sheet Images:

4.Hot-Dip Galvanized Steel Sheet Specification:

Standard: ASTM, JIS,EN

Grade: CS, DX51D+Z,SGCC, SS 230~550,S220GD+Z~S550GD+Z, SGC340~SGC570

Thickness: 0.1mm~5mm

Width: max 2000mm

Coil weight:3-12 MT

Coil ID:508/610mm

Surface structure: zero spangle, regular spangle or minimum spangle

Surface treatment: Chromate treatment, Oiled/dry, skinpassed/non-skinpassed

Packing: Standard seaworthy export package

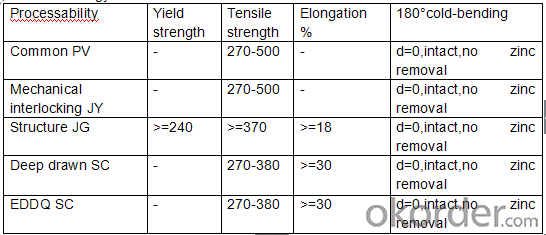

Technology test results:

5.FAQ of Hot-Dip Galvanized Steel Sheet:

We have organized several common questions for our clients,may help you sincerely:

1.How about your company?

A world class manufacturer & supplier of castings forging in carbon steel and alloy steel,is one of the large-scale professional investment casting production bases in China,consisting of both casting foundry forging and machining factory. Annually more than 8000 tons Precision casting and forging parts are exported to markets in Europe,America and Japan. OEM casting and forging service available according to customer’s requirements.

2.How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

3. How long can we receive the product after purchase?

Usually within thirty working days after receiving buyer’s advance payment or LC. We will arrange the factory manufacturing as soon as possible. The cargo readiness usually takes 15-30 days, but the shipment will depend on the vessel situation.

- Q:Are steel sheets heat resistant?

- Yes, steel sheets are generally heat resistant due to their high melting point and ability to withstand high temperatures without deforming or melting.

- Q:How do steel sheets handle bending or flexing?

- Steel sheets are highly malleable and can handle bending or flexing quite well. Due to their inherent strength and ductility, steel sheets can be easily bent or flexed without breaking or cracking, making them ideal for various applications in construction, manufacturing, and engineering industries.

- Q:Can steel sheets be used for elevator shafts or doors?

- Yes, steel sheets can be used for elevator shafts or doors. Steel is a commonly used material in the construction industry due to its strength, durability, and fire-resistant properties. It provides structural support and enhances the safety and security of elevator systems.

- Q:Can steel sheets be used for manufacturing automotive parts?

- Yes, steel sheets can be used for manufacturing automotive parts. Steel offers excellent strength, durability, and formability, making it a preferred material for various automotive components such as body panels, frames, and chassis.

- Q:Can steel sheets be used for shipbuilding?

- Yes, steel sheets can definitely be used for shipbuilding. In fact, steel is one of the most commonly used materials in shipbuilding due to its excellent strength, durability, and resistance to corrosion. Steel sheets are typically used to construct the hull, decks, and other structural components of a ship. The high tensile strength of steel allows ships to withstand the harsh conditions of the ocean, including heavy waves and extreme weather. Additionally, steel sheets can be easily fabricated and welded together, making them ideal for constructing large and complex ship structures. Overall, steel sheets are a reliable and efficient choice for shipbuilding.

- Q:What is the difference between a perforated and expanded steel sheet?

- A perforated steel sheet and an expanded steel sheet are both types of metal sheets commonly used in various industries. However, they differ in terms of their manufacturing process and resulting characteristics. Perforated steel sheets are created by punching or drilling holes into a solid steel sheet. These holes can be of various shapes, sizes, and patterns, depending on the desired application. The holes in a perforated steel sheet allow for the passage of air, light, sound, or fluids, making them suitable for applications that require ventilation, filtration, or acoustic properties. Perforated steel sheets are commonly used in industries such as architecture, automotive, filtration, and mining. On the other hand, expanded steel sheets are produced by a unique manufacturing process known as expanding. The process involves cutting and stretching a solid steel sheet, resulting in a mesh-like pattern with diamond-shaped openings. The stretching process imparts strength and rigidity to the steel sheet while also reducing its weight. Expanded steel sheets are versatile and can be used in applications such as walkways, platforms, fencing, grating, and reinforcement. In summary, the main difference between a perforated and expanded steel sheet lies in their manufacturing process and resulting characteristics. Perforated steel sheets have holes punched or drilled into them, allowing for the passage of air, light, sound, or fluids. Meanwhile, expanded steel sheets are created by cutting and stretching a solid sheet, resulting in a mesh-like pattern with diamond-shaped openings. Both types of sheets have their unique advantages and are chosen based on the specific requirements of the application.

- Q:What is muotileaved spring? What is the little leaf spring?

- In spring, the length of different, but the same as the total thickness of section steel plate spring, called multi leaf spring. The utility model is characterized in that the cross section of the spring leaf assembly is trapezoid with many pieces and large weight.In order to reduce the weight of the car, a new spring steel plate structure is adopted, which means that the middle section of the single spring is the thickest and becomes thinner at both ends. It is not a uniform section steel plate. This is a characteristic of equivalent plate to plate with several pieces of characteristics, therefore, the number of leaf spring assembly is reduced, and each piece of spring is tapered spring, the number of leaf spring assembly can be reduced to 2-3, and the performance achieved over the past 6-8 requirements. This spring assembly is called little leaf spring.The characteristics of few leaf spring is single leaf spring section is not equal, thick in the middle, two thin; the total number of small, light weight.

- Q:What is the price of each steel sheet?

- The price for each steel sheet can differ based on several factors like size, thickness, quality, and market conditions. To obtain an accurate and current price for the particular steel sheet you intend to buy, it is recommended to consult steel suppliers or manufacturers.

- Q:What are the common thicknesses for corten steel sheets?

- The common thicknesses for corten steel sheets range from 1.5mm to 16mm.

- Q:What is the process of applying anti-slip patterns to steel sheets?

- The process of applying anti-slip patterns to steel sheets typically involves using specialized equipment and techniques to create raised patterns on the surface of the sheets. This is often done through a process called embossing, where the steel is passed through a series of rollers or dies that imprint a textured pattern onto the surface. This pattern helps to provide traction and prevent slippage on the steel sheets, making them safer to walk on or handle in various applications.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Hot-dip Galvanized Steel Sheet/Coil in High Quality

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords