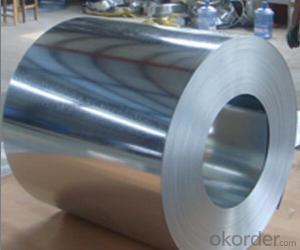

Hot-Dip Galvanized Steel Sheet and Coil of the Best Quality

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Structure of Hot-Dip Galvanized Steel Sheet Description:

Hot-dip galvanized steel coils are available with a pure zinc coating through the hot-dip galvanizing process. It offers the economy, strength and formability of steel combined with the corrosion resistance of zinc. The hot-dip process is the process by which steel gets coated in layers of zinc to protect against rust. It is especially useful for countless outdoor and industrial applications. Production of cold formed corrugated sheets and profiles for roofing, cladding, decking, tiles, sandwich walls, rainwater protective systems, air conditioning duct as well as electrical appliances and engineering.

2.Main Features of the Hot-Dip Galvanized Steel Sheet:

• Excellent process capability

• Smooth and flat surface

• Workability, durability

• Excellent anticorrosive property

• High strength

• Good formability

• Good visual effect

3.Steel Specification:

Thickness: 0.2-3.0mm

Width: 600-1500mm

Coating Mass: Z08,Z12,Z18,Z20,Z22,Z25,Z27,Z35

Z80,Z120,Z180,Z200,Z220,Z250,Z275

Tolerance for thickness,width,flatness and so on conform to the requirements of JIS G3302 or ASTM A653M/924M

Coil ID can be either 508mm or 610mm, maximum coil OD is 2000mm

The speicfication of ASTM Such as A653m,A924 M and so on have been updated to the latest revisions

4.Hot-Dip Galvanized Steel Sheet Specification

Standard: ASTM, JIS,EN

Grade: CS, DX51D+Z,SGCC, SS 230~550,S220GD+Z~S550GD+Z, SGC340~SGC570

Thickness: 0.1mm~5mm

Width: max 2000mm

Coil weight:3-12 MT

Coil ID:508/610mm

Surface structure: zero spangle, regular spangle or minimum spangle

Surface treatment: Chromate treatment, Oiled/dry, skinpassed/non-skinpassed

Packing: Standard seaworthy export package

Technology test results:

Processability | Yield strength | Tensile strength | Elongation % | 180°cold-bending |

Common PV | - | 270-500 | - | d=0,intact,no zinc removal |

Mechanical interlocking JY | - | 270-500 | - | d=0,intact,no zinc removal |

Structure JG | >=240 | >=370 | >=18 | d=0,intact,no zinc removal |

Deep drawn SC | - | 270-380 | >=30 | d=0,intact,no zinc removal |

EDDQ SC | - | 270-380 | >=30 | d=0,intact,no zinc removal |

5.FAQ of Hot-Dip Galvanized Steel Sheet

We have organized several common questions for our clients,may help you sincerely:

1.How about your company?

A world class manufacturer & supplier of castings forging in carbon steel and alloy steel,is one of the large-scale professional investment casting production bases in China,consisting of both casting foundry forging and machining factory. Annually more than 8000 tons Precision casting and forging parts are exported to markets in Europe,America and Japan. OEM casting and forging service available according to customer’s requirements.

2.How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

3. How long can we receive the product after purchase?

Usually within thirty working days after receiving buyer’s advance payment or LC. We will arrange the factory manufacturing as soon as possible. The cargo readiness usually takes 15-30 days, but the shipment will depend on the vessel situation.

Application:

BUILDING & CONSTRUCTION

Floor decks, ceilings, verandas, rolling doors, warehouse, partitions, sheds, gutters, wall, underground piping, sashes, beams, fences, scaffolding, indoor decorations, ducts, ventilating pipes, steel frames and cable trays.

ELECTRICAL APPLIANCES

Freezers, video recorder cases, motor cases, lighting fittings, water heaters, washing machines, refrigerators, stoves, air conditioners, dehumidifiers, fluorescent light housings, electrical heaters, toasters, microwave oven enclosures and switch boxes.

TRANSPORTATION

Containers, under body panels, bus & truck body panels, fuel tanks, noise screens, highway signs, air cleaners, conveyor systems and guard rails.

AGRICULTURAL EQUIPMENT

Barns, drying machines, animal houses, hoppers, irrigation systems, greenhouses, water tanks, sheds, silos, agricultural implements and feeders.

FURNITURE & OTHERS

Vending machines, drums, cans, pails, sauna inner parts, chimney pipes, entertainment machines, solar collectors, office equipment, steel furniture, tool boxes, garages and waste bins.

COMPUTER'S APPLIANCES

Computer shells and communication instruments。

Surface Treatment:

Chromating treatment or anti-finger print

Surface Finished:

REGULAR SPANGLE:

Regular spangle is also called normal spangle which is naturally formed without any additional treatment during galvanizing.

MINI SPANGLE:

The spangle is restrained and formed as mini spangle by reducing the lead content in the zinc liquid or by blowing the zinc powder from the equipment installed on the zinc pot.

EXTRA SMOOTH:

The mini spangle is further skin-passed to produce the extra smooth surface.

- Q:How are steel coils inspected for quality control purposes?

- Steel coils are inspected for quality control purposes through a combination of visual inspection, dimensional measurements, and various non-destructive testing techniques. This includes checking for surface defects, such as scratches or dents, as well as verifying the dimensions, weight, and shape of the coils. Additionally, technologies like ultrasonic testing, magnetic particle inspection, and X-ray examination are employed to detect internal defects, such as cracks or inclusions, ensuring that the steel coils meet the required quality standards.

- Q:What are the common methods of preserving steel coils?

- Some common methods of preserving steel coils include applying protective coatings, such as oil or paint, to prevent corrosion and rust formation. Another method is using VCI (Vapor Corrosion Inhibitor) paper or film, which releases chemicals that prevent oxidation. Additionally, steel coils can be stored in climate-controlled environments or wrapped in moisture-resistant materials to minimize exposure to moisture and humidity, which can accelerate corrosion.

- Q:How are steel coils used in the production of electrical appliances?

- Steel coils are used in the production of electrical appliances as the core component for electromagnets. These coils are wound around a metal core and when an electric current passes through them, they create a magnetic field which is essential for the functioning of various electrical components such as motors, transformers, and solenoids.

- Q:I'm doing a commercial for chemistry and I need to know any kind of chemistry dealing with Callaway Big Bertha Irons. I know they are stainless steel but any more info would help out! Thank you! :)

- Stainless steel is a mixture of metals, each metal is included in order to make up for each others weaknesses. Each metal is included due to a property that is benificial in some way, for instance Chromium is included because it makes the stainless steel 'stainless'. In chemistry a mixture of metals, stainless steel, is called an alloy.

- Q:What are the dimensions of steel coils used in the railway equipment industry?

- The dimensions of steel coils used in the railway equipment industry can vary depending on the specific application and requirements. However, common dimensions for railway steel coils typically range in thickness from 1.5mm to 25mm and in width from 600mm to 2000mm. The inner diameter of the coil is typically around 508mm, while the outer diameter can range from approximately 900mm to 2000mm.

- Q:What are the different types of steel coil surface treatment methods?

- There are several different types of steel coil surface treatment methods, including galvanizing, painting, powder coating, and pickling. Galvanizing involves applying a layer of zinc to the steel surface to protect against corrosion. Painting provides a decorative and protective coating by applying a layer of paint. Powder coating involves electrostatically applying a dry powder onto the steel surface, which is then cured to form a durable coating. Pickling is a chemical process that removes impurities and scales from the steel surface, resulting in a clean and smooth finish.

- Q:What are the different types of steel coil grades?

- There are several different types of steel coil grades used in various industries and applications. Some of the most common steel coil grades include: 1. Carbon Steel: This is a basic type of steel that contains mostly iron and carbon. It is widely used in construction, automotive, and manufacturing industries due to its high strength and durability. 2. Stainless Steel: This type of steel contains chromium, which provides corrosion resistance and makes it suitable for applications that require resistance to oxidation and staining. It is commonly used in the food processing, chemical, and medical industries. 3. High-Strength Low-Alloy (HSLA) Steel: HSLA steel contains small amounts of alloying elements such as copper, phosphorus, niobium, and vanadium. This type of steel offers higher strength and better mechanical properties compared to carbon steel, making it suitable for structural applications. 4. Galvanized Steel: Galvanized steel is coated with a layer of zinc to protect it from corrosion. It is commonly used in outdoor applications, such as roofing, fencing, and automotive parts. 5. Electrical Steel: Also known as silicon steel, electrical steel has high magnetic permeability, low electrical conductivity, and low core loss. It is used in the production of transformers, motors, and other electrical equipment. 6. Tool Steel: Tool steel is a high-carbon steel that is specifically designed for making tools and dies. It has excellent hardness, wear resistance, and toughness, making it suitable for cutting, forming, and shaping materials. These are just a few examples of the different types of steel coil grades available. Each grade has its own unique properties and characteristics, making it suitable for specific applications in various industries.

- Q:I'm looking to buy the Milano Stiletto, and it uses 1045 steel. I was just wondering whether this will hold up and keep an edge.

- 1045 Steel

- Q:How are steel coils measured for thickness?

- Steel coils are measured for thickness using a device called a micrometer or a thickness gauge. The micrometer is pressed against the coil's surface, and the measurement is displayed on its calibrated scale, providing an accurate reading of the steel coil's thickness.

- Q:How are steel coils used in the automotive industry?

- Steel coils are widely used in the automotive industry for various applications such as body panels, structural components, and engine parts. They are typically formed and shaped into desired forms through processes like stamping, bending, and welding. Steel coils provide strength, durability, and corrosion resistance to the vehicles, ensuring their safety and longevity.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Hot-Dip Galvanized Steel Sheet and Coil of the Best Quality

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords