Hot-Dip Galvanized Steel Roof with Competitive Price of China

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Hot-Dip Galvanized Steel Roof Description:

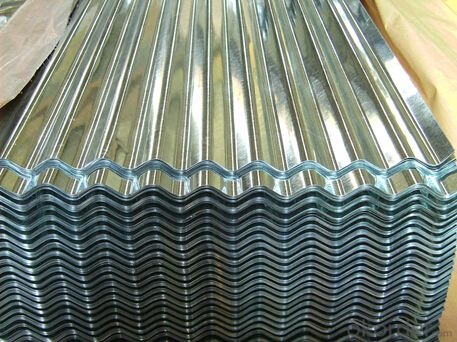

Hot-dip galvanized steel roof are available with a pure zinc coating through the hot-dip galvanizing process. It offers the economy, strength and formability of steel combined with the corrosion resistance of zinc. The hot-dip process is the process by which steel gets coated in layers of zinc to protect against rust. It is especially useful for countless outdoor and industrial application.

2.Main Features of the Hot-Dip Galvanized Steel Roof:

• Excellent process capability

• Smooth and flat surface

• Workability, durability

• Excellent heat resistance performance

• High strength

• Good formability

• Good visual effect

3.Hot-Dip Galvanized Steel Roof Images

4.Hot-Dip Galvanized Steel Roof Specification

Material: Galvanized Sheet

Width: 650/800/890/900

Length: 1500/1800/2000/2400/3005/3600 or customized

Thickness: 0.2-2.0

Surface Treatment: Hot dipped/Bended

Application: warehouse; shelter; Commercial facilities; industrial facilities

5.FAQ of Hot-Dip Galvanized Steel Roof

Which payment term we can do?

L/C at sight or T/T.

What’s the basic material of this product?

Galvanized/Aluzinc Steel

- Q:How are steel coils inspected for surface cleanliness during processing?

- Steel coils are inspected for surface cleanliness during processing using various methods such as visual inspection, magnetic particle inspection, eddy current testing, and ultrasonic testing. These techniques help identify any contaminants, defects, or imperfections on the surface of the coils, ensuring that the final product meets the required quality standards.

- Q:ive made lots of knives but they are dark and not shiny. how do i polish a knife and make it shiny

- Look for buffing compound at the hardware store. Home depot lowe's od even Wal-mart/ There is a compound for steel and for iron. I t will not make iron real shinny but it will make it look good. This stuff is to be used with a buffing wheel but I have used it on rags and it work great.

- Q:Are steel coils used in the packaging industry?

- Yes, steel coils are commonly used in the packaging industry for various purposes such as securing and stabilizing loads, protecting products during transportation, and providing structural support to packaging materials.

- Q:How are steel coils used in the production of industrial equipment?

- Steel coils are used in the production of industrial equipment as their versatile and durable nature makes them ideal for fabricating various components such as frames, structures, panels, and parts. These coils are processed and shaped into the required size and shape, allowing manufacturers to create sturdy and reliable equipment that can withstand heavy use and harsh environments.

- Q:How are steel coils inspected for yield strength using tensile testing?

- Tensile testing is the method used to inspect the yield strength of steel coils. This involves subjecting a sample of the coil to controlled tension until it reaches its breaking point. Through this test, various mechanical properties of the steel, including yield strength, can be determined. To conduct the tensile testing for yield strength inspection, a small strip of the coil is cut and prepared. The strip is then placed in a machine specifically designed for tensile testing. This machine consists of two grips that securely hold the strip at opposite ends. Subsequently, the machine applies a steadily increasing force to the strip, causing it to elongate until it eventually breaks. Throughout the test, the machine measures the force applied and the elongation of the strip. The yield strength is determined by identifying the point on the stress-strain curve where the material begins to undergo plastic deformation, meaning it exhibits permanent deformation without any increase in load. Typically, the yield strength is reported as the stress required to cause a specific amount of plastic deformation, such as 0.2% or 0.5%. This value represents the maximum stress that the steel can endure without experiencing permanent deformation. By performing tensile testing on a sample of the steel coil, it becomes possible to ascertain its yield strength. This information is vital in ensuring the quality and dependability of the steel coil, as it indicates the maximum stress it can tolerate before permanent deformation occurs. Furthermore, this testing method allows for the comprehensive evaluation of other mechanical properties, including ultimate tensile strength, elongation, and modulus of elasticity, thus providing a thorough understanding of the steel's performance characteristics.

- Q:A roll of 1 meters wide color steel roll about how many tons?

- Generally speaking, it will be about 4 tons, the export may be larger, but 10 tons of papers have not yet seen

- Q:a steel abr sells for about 879 now...a mith just over 1kany suggestions on which-keyword WHICH steel item to make-which is the best-exp wise, and steel bar conservative wise.

- Mining okorder /

- Q:I need to identify a metal. It is rusty so I suspect it is either iron or steel. Since they both have similar densities and are magnetic, how do I tell the difference betweeen steel and iron?

- Iron and Steel Manufacture, technology related to the production of iron and its alloys, particularly those containing a small percentage of carbon. The differences between the various types of iron and steel are sometimes confusing because of the nomenclature used. Steel in general is an alloy of iron and carbon, often with an admixture of other elements. Some alloys that are commercially called irons contain more carbon than commercial steels. Open-hearth iron and wrought iron contain only a few hundredths of 1 percent of carbon. Steels of various types contain from 0.04 percent to 2.25 percent of carbon. Cast iron, malleable cast iron, and pig iron contain amounts of carbon varying from 2 to 4 percent. A special form of malleable iron, containing virtually no carbon, is known as white-heart malleable iron. A special group of iron alloys, known as ferroalloys, is used in the manufacture of iron and steel alloys; they contain from 20 to 80 percent of an alloying element, such as manganese, silicon, or chromium.

- Q:What are the common coil grades available for steel coils?

- Steel coils come in different grades, each with its own distinct properties and uses. Some commonly used grades include: 1. HRC (Hot Rolled Coils): These coils are made by heating a steel slab to its recrystallization temperature and rolling it into a coil. HRC coils are known for their excellent weldability and formability, making them suitable for various applications like construction, automotive manufacturing, and general engineering. 2. CRC (Cold Rolled Coils): CRC coils are produced by further processing HRC coils through cold reduction, which involves passing the steel through rollers at room temperature. CRC coils have a superior surface finish and dimensional accuracy, making them ideal for applications that require a smooth and uniform appearance, such as automotive body panels, appliances, and electrical equipment. 3. GI (Galvanized Coils): GI coils are created by coating regular carbon steel coils with a layer of zinc through a hot-dip galvanizing process. This provides excellent corrosion resistance, making GI coils suitable for outdoor applications like roofing, fencing, and structural components. 4. Stainless Steel Coils: Stainless steel coils are made from different grades, with the most common being austenitic (such as 304 and 316) and ferritic (such as 430). Stainless steel coils offer excellent corrosion resistance, high temperature resistance, and aesthetic appeal, making them widely used in industries like food processing, chemical processing, and architecture. 5. EG (Electro-galvanized Coils): EG coils are similar to GI coils, but the zinc coating is applied using an electrolytic process instead of hot-dipping. EG coils have a thinner and smoother zinc layer, making them suitable for applications that require a brighter and more aesthetic appearance, such as automotive parts, appliances, and decorative items. These are just a few examples of the coil grades available for steel coils. The choice of the right grade depends on factors like the intended application, required mechanical properties, and desired aesthetics. It is important to seek guidance from steel suppliers or industry experts to determine the most suitable coil grade for a specific application.

- Q:I know that carbon steels and alloy steels are different but are carbon steels still alloys?Thanks!

- Yes. it's an alloy of iron and carbon. Carbon steel can either mean plain carbon steel which is steel that doesn't have significant amounts of other elements, like chromium, manganese, or molybdenum. It can also be used to refer to ANY steel that is NOT a stainless steel. Alloy steel is any steel that has greater than 1% of other elements added to it besides carbon. Stainless steel might be in a certain sense be considered alloy steel but I think most people in the steel business consider it as it's own separate material from carbon steels. Many stainless steels contain only trace amounts of carbon, so they should rightly be considered iron-chromium alloys, not steel, which by default refers to iron-carbon alloys. Note that nearly all modern carbon steels also contain 0.2%-0.5% manganese and silicon. Even steels that are otherwise considered plain carbon and not alloy steels. Mn and Si are added because they prevent defects in cast steel ingots, and hot rolled items like billets and plates. However at low levels they don't affect the properties of the steel greatly.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Hot-Dip Galvanized Steel Roof with Competitive Price of China

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords