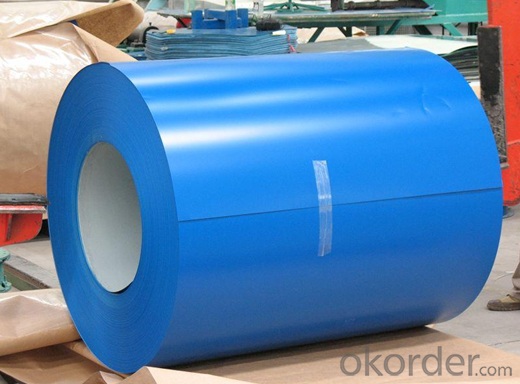

Hot-Dip Galvanized Steel/Pre-Painted Steel Coil for Tiles Thicness0.18mm-1.5mm Width900mm-1250mm

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 1000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications;

1. Aluzinc coating mass: 30g-275g/sqm

2. Coil weight: 4-6 tons per coil

3. Edge treatment: Mill edge or cut edge.

4. Technical treatment: Bright annealed, flatting, cold harden.

5. Surface treatment: Annealed, bright finish, dull/bright finish, slit edge.

6. Spangle: Normal/small/big/zero spangle.

7. Delivery terms: FOB / C&R / CIF

8. Supply Ability: 30000MT/month

9. Application: The construction industry: The roof structure, keel, grill, Clapboard, ceilings, fire shutter doors, etc; The light industry, the Automobile, agriculture, animal husbandry, fishery, casing of household Electronic application, civilian smoke stack, etc.

10. Delivery time: Within 30 days after the receipt of L/C or Signed the contract or according to customer's requirement.

Special design available according to requirement; Anti-corrosion And high-temperature resistant with black painting; All the production process Are made under the ISO9001: 2000 strictly

Terms of payment | T/T, L/C or T/T and L/C |

Delivery Detail | within 7-25 days after receiving pre-payment (as per the order quantity) |

Coil ID | 508mm/610mm |

Coil Weight | 3-5 tons |

Supply Ability | 30000MT per month |

Application | Construction Structure, roofing, commercial use, household appliance, industry- |

PPGI,(PPGL,pre-painted galvanized steel coils, pre-painted galvalume steel coils,color coated steel coils.color coated galvanized steel coils)

1, Introduction: PPGI is made of galvanized steel coils or galvalume steel coils with polymer coatings as surface. It's a new enclosure material and building board

2, Product feature: Apperance of a variety of color Antirust and antiseptic,durability,etc.

3, Production Process: Pretreatment(Degreasing) DryingChromatingPaint Basic OilCoolingDryingColor CoatingCoolingFilm- coveringRolling Up

4, Application: it is ideal for a wide range of applications,, such as pre-engineered buildings, architectural panels, roofing, siding, cladding, and many other building components.and also used back plate of appliance; wide range of construction, furniture industry, transportation industry, etc.

FAQ

1.Are the products tested before shipping?

Yes, all of our PPGI and GI was qualified before shipping. We test every batch every day.

- Q:What are the different types of steel coil storage locations?

- There are various types of steel coil storage locations, including open yards, covered warehouses, coil racks, and specialized coil storage systems.

- Q:What are the common methods of handling steel coils during production?

- There are several common methods for handling steel coils during production. These methods are designed to ensure the safe movement and storage of the coils, as well as to facilitate efficient processing. 1. Forklifts: Forklifts are commonly used to move steel coils within a production facility. They are equipped with specialized attachments, such as coil rams or coil hooks, that securely grip the coil and allow for easy transport. Forklifts are ideal for moving coils over short distances or between different areas of the production floor. 2. Overhead cranes: Overhead cranes are another popular method for handling steel coils. These cranes are typically mounted on rails and can span the entire length of a production facility. They use lifting devices, such as C-hooks or magnets, to securely lift and transport the coils. Overhead cranes are particularly useful for moving large or heavy coils over longer distances. 3. Coil cars: Coil cars are specialized rail-mounted vehicles that are designed to transport steel coils within a production facility or between different areas of a steel mill. These cars feature adjustable arms or forks that can be positioned to securely hold the coils. Coil cars are often used when large quantities of coils need to be moved at once. 4. Coil racks: Coil racks are used for storing steel coils in a vertical position. These racks are typically made of heavy-duty steel and are designed to hold multiple coils securely. They are commonly used in warehouses or storage yards to maximize space and facilitate easy access to the coils. 5. Coil trailers: Coil trailers are specially designed trailers that are used for transporting steel coils over long distances. These trailers have built-in coil cradles or bunks that securely hold the coils during transit. They often feature adjustable or removable coil racks to accommodate different sizes or configurations of coils. Overall, the common methods of handling steel coils during production involve the use of specialized equipment such as forklifts, overhead cranes, coil cars, coil racks, and coil trailers. These methods prioritize the safety of the workers and the integrity of the coils, while also ensuring efficient movement and storage throughout the production process.

- Q:i want a good modern carbon steel (not stainless) knife. trying to keep it under 50$ also nothing to gruesome just a small pocket knife. thank you

- Well, okorder /... They did make other folders in M2 steel, but the thing is those are out of production and the cost is very high. Spyderco made M4 steel folder knives, and so did Benchmade. Although,both are outside of 50$ budget. I guess Opinels are best option.

- Q:How are steel coils used in the production of kitchen appliances?

- Steel coils are used in the production of kitchen appliances as they are transformed into various components such as panels, doors, and frames. These coils are typically cut, shaped, and welded into desired forms, providing strength, durability, and a sleek finish to the appliances.

- Q:I live in Dubai. I want to make a damascus steel sword and have no idea where to get the steel or what sort of steel I should get.First to adress the access of my steel...I need to get some low carbon and high carbon steel for the Damascus....what sort of steel is recommended for this? Also where would I be able to get my hands on it (Internet options e.g websites or locations)THANKS

- hI Jordan damascus steel is not actually a steel it is a composite material like the damascus rifle barrels the Afghan's use it is made from wire wrapped around an inner mandrel the beaten on an anvil till all the wire becomes one so it is several types of iron and steel beaten together and forged to produce it so it is not something you can actually buy as a material the tribesmen that produce these swords have these secret methods of doing this so there is the first problem. it is not like cast steel which is what most swords are made of it is far more complex in it's construction. so you may need to do a lot of research to find out how. what is a similar idea is the SAMURAI sword that is made up of combining different steels together and forged into a very sharp and capable killing blade.

- Q:How are steel coils used in the production of marine vessels?

- Due to their strength, durability, and versatility, steel coils find extensive use in the production of marine vessels. These coils, typically made of high-quality steel, possess the ability to withstand harsh marine environments and resist corrosion. The construction of the hull is one of the primary applications of steel coils in marine vessel production. Welding together steel coils that have been formed into plates creates the hull structure. The coils' strength ensures that the hull can endure the extreme forces and pressures encountered during vessel operation, including rough seas and heavy cargo loads. Furthermore, steel coils are employed in the production of various components and fittings within marine vessels. These coils can be shaped, cut, and formed into different parts like bulkheads, decks, and superstructures. The versatility of steel enables manufacturers to create intricate shapes and structures necessary for the efficient and safe functioning of a marine vessel. Moreover, steel coils are also used for fabricating pipes and tubing systems within marine vessels. These pipes are crucial for tasks such as fluid and fuel transportation, as well as ventilation throughout the vessel. The strength and corrosion resistance of steel coils ensure that these pipes can endure the high pressures and corrosive nature of marine environments. Additionally, steel coils are utilized in the production of marine vessel equipment like winches, cranes, and anchor systems. The components demand a material with high strength that can withstand heavy loads and constant use. Steel coils provide the necessary strength and durability to ensure the reliable performance of these vital equipment. In conclusion, steel coils play a crucial role in the production of marine vessels. Their strength, durability, and versatility make them an ideal material for constructing the hull, manufacturing various components, fabricating piping systems, and creating equipment. The use of steel coils guarantees the safety, efficiency, and longevity of marine vessels, enabling them to navigate the challenging conditions of the open seas.

- Q:Can steel coils be bent or shaped?

- Yes, steel coils can be bent or shaped. Steel coils are flexible and can be easily manipulated into various forms or shapes through processes like bending, rolling, or stamping.

- Q:hello, just wondering if there is such a thing as a stainless steel coating for my aluminum muffler prior to installation. Yes, i suppose you can say that im cutting corners, but my current finances wont allow me to pay full price for a stainless steel one, thnx

- Not as of now maby latter but not now ,

- Q:How is the demand for steel coils influenced by the construction sector?

- The demand for steel coils is heavily influenced by the construction sector. As construction activities increase, so does the demand for steel coils as they are essential for various construction applications such as structural components, roofing, and reinforcing materials. Conversely, when construction activities decline, the demand for steel coils also decreases. Therefore, the construction sector plays a crucial role in driving the demand for steel coils.

- Q:What are the dimensions of steel coils used in the metal container industry?

- The metal container industry can have different requirements and produce various types of containers, leading to varied dimensions for steel coils. However, generally, the thickness of steel coils used in this industry falls between 0.3mm and 3mm, while the width ranges from 600mm to 2000mm. In terms of shape, the coils are commonly wound in a continuous spiral form with diameters ranging from 600mm to 1500mm. These dimensions enable effective production and handling of the steel coils throughout the manufacturing process of metal containers.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Hot-Dip Galvanized Steel/Pre-Painted Steel Coil for Tiles Thicness0.18mm-1.5mm Width900mm-1250mm

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 1000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords