Hot Dip Galvanized Frame Scaffolding 1219*1700*42*2.0 CNBM

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 pc

- Supply Capability:

- 30000000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

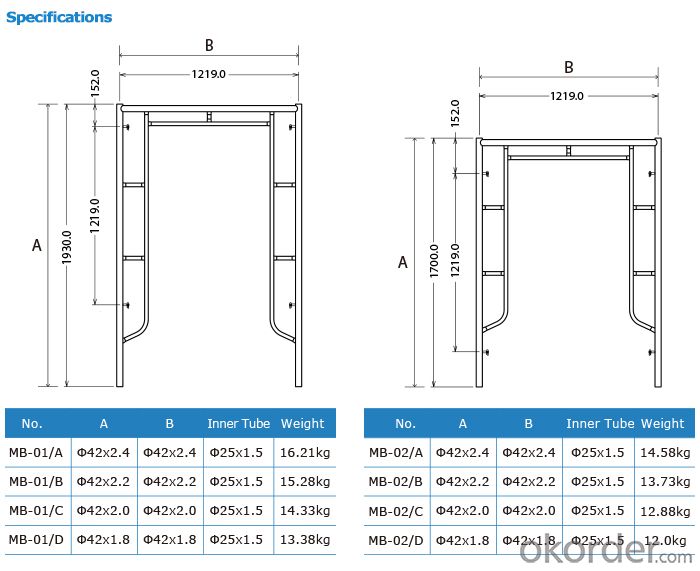

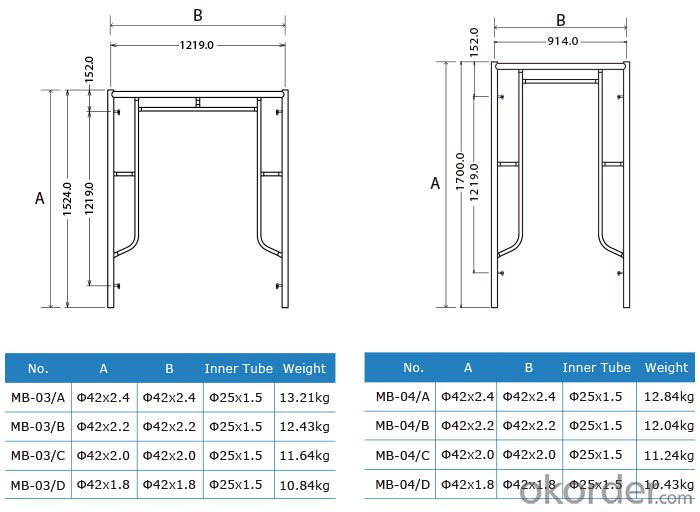

Description of Hot Dip Galvanized Frame Scaffolding 1219*1700*42*2.0

Material :Q195 (Carbon 195 Steel)

Size : 1219*1700*42*2.0

Surface treatment :galvanized

Color : silver

Standard: BS1139

Hot Dip Galvanized Frame Scaffolding 1219*1700*42*2.0 Futures:

A Light & Safe Frame Scaffolding System with low cost.

Integrated with the formwork, Toe-board, the cross diagonal tie pole, steel plank, and adjustable support base.

The scissors-style push-pull prop designs ensure the high-performance stiffness & load-carrying property

The φ36 connecting rods exert an equal pressure.

The Surface galvanized plug-pin firmly connected the pull prop & main frame.

Adopt the CO2 gas protection welding technology ensures the superior corrosion & oxidation resistance.With Universal wheel (scaffolding wheel).

What's your products advantages?

Experience: over ten years in scaffolding manufacturing.

Quality: Certified by SGS, BS1139, EN74, Local Test Report.

Price: Moderate, Reasonable.

Service: Friendly and Responsible. OEM service is available.

- Q:I know its between chapters one and two, duh. Haha, but yeah, I needa do this thing on Edmodo for school, but i accidentally left my book in my locker.):I tried looking at online versions, but you know it's so hard, right? Looking and seeing all these different versions and I cant find the place...I need where she entered the scaffold because I need to cite where she thinks about how she's accepted her quot;sinquot;. So yeah~ PLEASE HELP! ( gt; . lt; )

- i'm no longer completely constructive of the answer to this actual question, yet I only finished a unit in this novel and could like to help with any extra questions...be satisfied to invite -Alice

- Q:Who has external scaffolding construction program

- 1.1.2 fastener1 steel tubular scaffold made of malleable iron fasteners, the material should be consistent with current national standard "steel pipe scaffolding fasteners" (GB15831) regulations; the fastener made by other materials used, test show that the quality meets the standard requirements before use.2 fastener used in the scaffold, bolt tightening torque up to 6.5N.M, shall not be damaged.1.1.3 foot plateThe scaffold made of bamboo or bamboo bamboo string plate, each quality should not be greater than 30kg.1.1.4 wall partsThe material of the wall parts shall be in accordance with the provisions of the current national standard "Q235-A" (GB/T700).1.2 inspection of qualified parts should be classified according to the varieties, specifications, stacked neatly, smooth, stacking sites may not have water.1.3 should be cleared to set up the site debris, flat set up the site, and make water flow.1.4 when the foundation of the scaffold has equipment foundation, pipe trench, the scaffolding should not be used in the process of excavation, otherwise it is necessary to take reinforcement measures.

- Q:Who knows how much the amount of the main material used to take one square metre of conventional double row scaffolding (within 12 meters). For example, how many kilograms of steel pipe, the number of fasteners. The content of the quota is low, I am also very confused, to the completion of the work of the scaffolding rental fees. Very urgent, I hope to know the user to answer. Accident report

- The following is a quote fragment: who knows how to use a square meter of the main raw material of double row scaffolding

- Q:For the current stage of China's construction should not strengthen the specific meaning of scaffolding and support by way of the scaffolding and support the specific distinction and significance

- At the present stage Chinese people-oriented, building a harmonious society, especially the importance of safety in production site, in addition to constantly modify the security specifications and technical documents issued by a variety of real-time safety, strengthen safety measures, compulsory accident insurance and so on. JGJ130-2011 is the new version of the construction of steel tubular scaffolding safety technical specifications should be strengthened scaffolding construction management. The current JGJ162-2008 is the safety technical specification for the construction of fastener type steel pipe formwork support.

- Q:I know the ivy sort of glues itself to whatever surface with little sticky pads so that will take care of itself on the back of my house but can I use the existing Ivy for the wisteria to grab onto and climb up or will the wisteria be too heavy and pull the ivy down? I'd rather avoid having to build something for the wisteria to wrap itself around. Any suggestions? Thanks! : )

- No, ivy isn't that strong. One can easily unzip it from the walls. Wisteria is way too heavy for ivy. Plus you have the root competition down below. Ivy creates an incredible dense mat of roots , little grows with it. Wisteria would have quite a battle on its hands for root space and nutrients.

- Q:Standard Specification for bowl buckle scaffold

- Compared with other types of scaffolding, bowl buckle type multifunctional scaffolding is a new scaffold with broad development prospects.

- Q:What is the bowl buckle scaffolding, bowl buckle scaffold what are the characteristics

- (1) main componentComponent for forming the main body of a scaffold. The vertical rod and the top rod are respectively provided with two kinds of specifications, and both sides of the rod are welded with a lower bowl buckle with a spacing of 600mm. If the vertical rod and the ejector rod are matched with each other for long use, the utility model can form an arbitrary height scaffold. Take a long pole, the joints should be staggered, the top layer and then leveling rod length two.

- Q:So I had a scaffold/industrial done about 10 weeks ago, and its been infected at the top hole only for about 3/4 weeks. It has like a little bubble near the hole and sometimes its filled with pus a little bit and sometimes its not. Well I went the doctors about 2 weeks ago and he prescribed me a weeks worth of antibiotics as well as anti-septic cream. So I took the pills for a week and it was clearing up, I was also applying the cream twice a day. But then yesterday I noticed the lump has gotten a little bit bigger. I don't know what to do, should I take it out? But I really don't want to. And plus the doc said to wait up to 3 weeks and if nothings changed to go back and take it out. If I continue to use the cream, will it eventually go? Thanks :)

- If so, its hypertrohic scarring, a common occurence in cartilaginous piercings caused by too much jewelry movement/improperly fitted jewelry. It can be treated by applying tea tree oil to the bump once or twice a day.

- Q:What are scaffold spanners used for?

- Ratchet Podger Spanners...Aluminium Scaff Spanners Spanners are wide wrenches that are made from durable metals. Spanners are made specifically for scaffolding and are designed to fit into the tool belt nicely. Spanners are very useful for a number of jobs and are often used along with other scaffold tools on a safety lanyard to prevent dropping the tool to the street below. Spanners work the same as traditional wrenches but like many scaffolding tools are made with a hole in the end of the wrench for the safety strap to be inserted through. Stainless steel and aluminum are the most commonly used metals for spanners to ensure durability even if the item is dropped from high.

- Q:I want to know the classification of scaffolding in the building

- Steel tubular scaffold. As to the steel pipe, and combined with other type of steel pieces composed of scaffolding, such as the channel has a base in the backwater or scaffolding, connecting steel scaffolding and so on. ScaffoldingBowl buckle steel pipe scaffolding when using steel pipe, as a "single steel pipe scaffolding"; when using the steel cross bar, for the "steel pipe based scaffold".

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Hot Dip Galvanized Frame Scaffolding 1219*1700*42*2.0 CNBM

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 pc

- Supply Capability:

- 30000000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords