Hot-Dip Galvanized/Aluzinc Steel Coil in High Quality

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Hot-dip Zinc Coating Steel Building Roof Walls

1.Structure of Hot-Dip Galvanized Steel Sheet Description:

Hot-dip galvanized steel coils are available with a pure zinc coating through the hot-dip galvanizing process. It offers the economy, strength and formability of steel combined with the corrosion resistance of zinc. The hot-dip process is the process by which steel gets coated in layers of zinc to protect against rust. It is especially useful for countless outdoor and industrial applications. Production of cold formed corrugated sheets and profiles for roofing, cladding, decking, tiles, sandwich walls, rainwater protective systems, air conditioning duct as well as electrical appliances and engineering.

2.Main Features of the Hot-Dip Galvanized Steel Sheet:

• Excellent process capability

• Smooth and flat surface

• Workability, durability

• Excellent anticorrosive property

• High strength

• Good formability

• Good visual effect

3.Hot-Dip Galvanized Steel Sheet Images:

4.Hot-Dip Galvanized Steel Sheet Specification:

Standard: ASTM, JIS,EN

Grade: CS, DX51D+Z,SGCC, SS 230~550,S220GD+Z~S550GD+Z, SGC340~SGC570

Thickness: 0.1mm~5mm

Width: max 2000mm

Coil weight:3-12 MT

Coil ID:508/610mm

Surface structure: zero spangle, regular spangle or minimum spangle

Surface treatment: Chromate treatment, Oiled/dry, skinpassed/non-skinpassed

Packing: Standard seaworthy export package

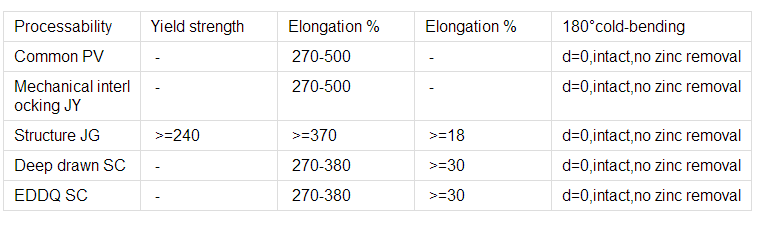

Technology test results:

5.FAQ of Hot-Dip Galvanized Steel Sheet:

We have organized several common questions for our clients,may help you sincerely:

1.How about your company?

A world class manufacturer & supplier of castings forging in carbon steel and alloy steel,is one of the large-scale professional investment casting production bases in China,consisting of both casting foundry forging and machining factory. Annually more than 8000 tons Precision casting and forging parts are exported to markets in Europe,America and Japan. OEM casting and forging service available according to customer’s requirements.

2.How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

3. How long can we receive the product after purchase?

Usually within thirty working days after receiving buyer’s advance payment or LC. We will arrange the factory manufacturing as soon as possible. The cargo readiness usually takes 15-30 days, but the shipment will depend on the vessel situation.

- Q:How are steel coils recycled?

- Steel coils are typically recycled by first being collected and transported to a recycling facility. At the facility, the coils are unpacked and sorted based on their type and quality. Any contaminants, such as oil or paint, are removed through a cleaning process. The coils are then shredded into smaller pieces and melted in a furnace. Once melted, impurities are skimmed off the top, and the molten steel is poured into molds to form new coils or other steel products. This process helps conserve resources and reduce the need for mining new materials.

- Q:Can steel coils be customized?

- Yes, steel coils can be customized to meet specific requirements such as size, shape, thickness, and surface finish. Customization can be done through processes like cutting, slitting, shaping, and coating to ensure that the steel coils are tailored to the desired specifications.

- Q:I live in the Black Hills and I need to re-side my cottage. I like the look of vinyl. I've heard pros and cons about both steel and vinyl. Is steel really that easy to dent? It just doesn't look as 'clean' as vinyl. Also what 3 color combos do you like? My cottage has shutters.

- I'd like to know why you need to re-side it. I would get vinyl because it will not need painting as soon as steel.

- Q:i like stainless steel guns, especially the SW 686 .357, i plan on getting one but my question is would polishing the stainless steel make the gun more prone to corrosion over leaving it as it is? and will the polished surface appear uneven after use and sitting? obviously all metal takes some sort of upkeep but is polished more high maintenance than non-polished?

- The SW 686 is a great revolver. I have the model 586 (blued) and intend to get a 686 and do the same thing - polish it to a mirror finish. There is a great video on YouTube that shows a man polishing his stainless steel revolvers to a mirror finish. He uses Mother's Mag Wheel Polish. Polishing the gun to a bright mirror finish will not in any was reduce the rust resistance of the metal. However, it will do two things. First, it will show scratches and flaws more over time. So if the gun gets mishandled, you will notice the marks on the finish. Second, when shooting in bright sunlight, you might not be able to aim the gun at all. I've had this happen to me with the old polished nickle finish revolvers; I had a Colt Diamondback with a bright nickle finish and it was impossible to aim when the sun was beating down on it. For a fun project gun, I think that a polished stainless finish is neat. It's not something I would want to use for hunting or personal protection, but sort of a bragging piece at the gun range.

- Q:Theirs this two handed chinese sword on amazon with a forged combat steel blade and i was wandering if it means combat steel in the same sense that tempered carbon steel can be used?

- Great answer by JayDub. Amazon isn't exactly a great site for legitimate sword shopping. Look for legitimate retailers specializing in handmade swords.

- Q:So I was thinking about doing corset waist training and I wanted to know where I can get a real steel boned corset?

- Hi, okorder / There are 3 types of corsets: Fashion corsets, Authentic corsets and Waist training corsets. The fashion corsets are designed for light enclasping of body. They are made with plastics bones usually. The authentic corsets can reduce your waist size about 4 - 5 and the waist training corsets about 6. They both are made with steel spirals and flat bones. The waist training corsets are recommended for experienced wearers only. Look on info pages of the seller. The corsets reinforced with plastic bones are cheap with low durability.

- Q:the comparison needed between other steel

- BECAUSE IT HAS HIGH STRENGTH. IT HAS HIGH TOUGHNESS IT HAS LOW PERCENTAGE OF CARBON 0.05% TO 0.30% CAN BE USED AS GEARS,CRANKSHAFT

- Q:How are steel coils used in the production of fencing materials?

- Steel coils are used in the production of fencing materials as they serve as the raw material for manufacturing various types of fencing products, such as chain-link fences, barbed wires, and welded wire meshes. The steel coils are unwound and processed through different manufacturing processes, including cutting, shaping, and welding, to create the desired fencing products. The strength and durability of steel make it an ideal material for fencing, providing security and protection in various applications, such as residential, commercial, and industrial settings.

- Q:I need details for steel column splices welded or bolted. References or autocad blocks will be very useful. Thank you very much!

- The refernce for Canada is S16-01 Limit states steel design My professor always taugth us shop weld field bolt if that helps

- Q:What are the different methods of coil handling and storage?

- Various industries commonly employ several different methods for coil handling and storage to ensure safety, efficiency, and preservation. Some of these methods include: 1. Coil cradles: Popular for handling and storing coils, coil cradles feature a U-shaped structure that provides stability and support. The cradle is positioned beneath the coil and can be easily maneuvered using forklifts or overhead cranes. 2. Coil cars: Used for transporting coils within a facility or between locations, coil cars are equipped with specialized clamps or arms to securely hold the coil during transit. Manual or automatic operation is determined by coil size and weight. 3. Coil racks: Specifically designed storage systems for organized coil storage, coil racks are typically constructed from steel and feature multiple levels or compartments to accommodate various coil sizes and types. Forklifts or overhead cranes are used to access coil racks. 4. Coil turnstiles: In processing lines where continuous coil feeding into machines is required, coil turnstiles are employed. These rotating devices enable easy loading and unloading of coils by rotating them to the desired position, facilitating handling and processing. 5. Coil pallets: Specially designed pallets made of steel or wood, coil pallets are utilized for both storage and transportation of coils. Their unique configuration allows for convenient loading and unloading using forklifts or pallet jacks. Coil pallets are often utilized for long-distance transportation or warehouse storage. 6. Coil storage racks: Large storage systems designed for bulk coil storage, coil storage racks are typically made of steel and feature multiple levels or compartments to accommodate a significant number of coils. Forklifts or overhead cranes are utilized for accessing coil storage racks. These examples represent only a selection of the numerous coil handling and storage methods commonly employed across various industries. The specific method chosen depends on factors such as coil size and weight, available space, and industry-specific requirements.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Hot-Dip Galvanized/Aluzinc Steel Coil in High Quality

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords