Hot-Dip Galvaniume Steel Sheet of Every Size

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 30 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Structure of Hot-Dip Galvanized Steel Sheet Description:

Hot-dip galvanized steel coils are available with a pure zinc coating through the hot-dip galvanizing process. It offers the economy, strength and formability of steel combined with the corrosion resistance of zinc. The hot-dip process is the process by which steel gets coated in layers of zinc to protect against rust. It is especially useful for countless outdoor and industrial applications. Production of cold formed corrugated sheets and profiles for roofing, cladding, decking, tiles, sandwich walls, rainwater protective systems, air conditioning duct as well as electrical appliances and engineering.

2.Main Features of the Hot-Dip Galvanized Steel Sheet:

1) Buildings and constructions: roofing, ceilings, gutters, venting lines, indoor decorations, window frames, etc.

2) Electrical appliances: computer shells, washing machines, refrigerators, dehumidifiers, video recorders, water heaters, etc.

3) Agricultural equipments: troughs, feeding tools, agricultural driers, irrigation channels, etc.

4) Vehicle parts: back-seat plates of buses and trucks, conveying systems, oil tanks, etc.

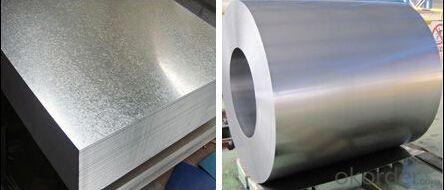

3.Hot-Dip Galvanized Steel Sheet Images

4.Hot-Dip Galvanized Steel Sheet Specification

Standard: ASTM, JIS,EN

Grade: CS, DX51D+Z,SGCC, SS 230~550,S220GD+Z~S550GD+Z, SGC340~SGC570

Thickness: 0.1mm~5mm

Width: max 2000mm

Coil weight:3-12 MT

Coil ID:508/610mm

Surface structure: zero spangle, regular spangle or minimum spangle

Surface treatment: Chromate treatment, Oiled/dry, skinpassed/non-skinpassed

Packing: Standard seaworthy export package

Technology test results:

Processability | Yield strength | Tensile strength | Elongation % | 180°cold-bending |

Common PV | - | 270-500 | - | d=0,intact,no zinc removal |

Mechanical interlocking JY | - | 270-500 | - | d=0,intact,no zinc removal |

Structure JG | >=240 | >=370 | >=18 | d=0,intact,no zinc removal |

Deep drawn SC | - | 270-380 | >=30 | d=0,intact,no zinc removal |

EDDQ SC | - | 270-380 | >=30 | d=0,intact,no zinc removal |

5.FAQ of Hot-Dip Galvanized Steel Sheet

We have organized several common questions for our clients,may help you sincerely:

1.How about your company?

A world class manufacturer & supplier of castings forging in carbon steel and alloy steel,is one of the large-scale professional investment casting production bases in China,consisting of both casting foundry forging and machining factory. Annually more than 8000 tons Precision casting and forging parts are exported to markets in Europe,America and Japan. OEM casting and forging service available according to customer’s requirements.

2.How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

Pay off reel-double cut shear-jonter-pre cleaning section-dryer-entry accumulation-cleaning section-chemical coater-chemical oven-primer coater-prime oven-prime coater cooling unit-dryer-finish coater-finish oven-finish coater cooling unit-dryer-tension leveler-exit accumulator-exit shear-tension reel

- Q:How are steel coils used in the production of storage systems?

- Steel coils are used in the production of storage systems by being formed into sheets or strips, which are then shaped and welded to create the framework and shelves of the storage units. The high strength and durability of steel make it an ideal material for supporting heavy loads and ensuring the longevity of storage systems.

- Q:What is the (balanced) chemical equation for steel?

- I hate to differ but I must. Steel is a mixture of iron and carbon but the carbon content ranges from a small fraction of a percent to no more than 2%. Stainless steel is an alloy of Iron and up to 15% or so of other metals but since there are several types and many varieties in each type it's hardly worth getting into. A good common hardenable high-carbon spring steel is AISI 1095. In this code the 95 refers to 0.95% carbon. When the carbon level goes up to 1.5% to 2% the steel is very brittle and black with the highest carbon steel being pretty much pig-iron.

- Q:Can steel coils be stored vertically?

- Yes, steel coils can be stored vertically.

- Q:How do steel coils impact the overall cost of production?

- Steel coils can have a significant impact on the overall cost of production. The cost of steel coils is a major component in the production process, as they are used as raw materials in various industries such as automotive, construction, and manufacturing. Fluctuations in the price of steel coils can directly affect the cost of production, ultimately influencing the final price of the end product. Additionally, factors such as transportation and storage costs also contribute to the overall impact of steel coils on production costs.

- Q:I want to make an object out of stainless steel. Initially, I had planned to get it cut out of stainless steel sheet but several of the edges need to be rounded and I think it would be much cheaper to get it made of cast iron formed in a mold.Yet, it must be stainless steel. Can stainless steel be formed in a mold like iron can ... i.e. poured in liquid form into a mold and harden into shiny stainless steel?Would a regular foundry do this or do I need something special?Thanks.

- You have 2 options. Sand casting or investment casting. Stainless steel can be cast with either of these methods. In either case a model or pattern will have to be created. For sand casting the pattern is all that is needed to go to casting. For investment casting the pattern is used to make a wax casting, which is then coated with the investment. The wax is burned out and the metal is then poured into the cavity. If you are making just 1 or 2 pieces you can have waxes machined. This saves the intermediate step Depending on the size machining may still be your best option. Especially if you want just 1 part.

- Q:What are the different types of steel coil welding methods?

- There are three main types of steel coil welding methods: butt welding, lap welding, and flash welding. Butt welding involves joining two ends of steel coils by aligning them and welding them together. Lap welding, on the other hand, involves overlapping the ends of the coils and welding them together. Flash welding is a method where the ends of the coils are placed in contact with each other and a high electric current is passed through them to create a weld.

- Q:I want to replace the old refrigator within the next 6 months........ Is the trend to buy a stainless steel refrigerator? Some magazines and internet sites are pointing me that direction. What are the pro's and con's ? I like the color bisque, or cream-color as well, or better, than stainless steel. What would be the reasons to buy stainless steel...is it becoming the most popular color ?

- I'm looking too and certainly the designer trend is to buy stainless steel. They look classy, shiny and bring a darker wood kitchen more life. However, there are companies that have put out fingerprint/smudge free stainless models. I have found their surfaces don't retain fingerprints - do test them in the store.If you have small children, stainless isn't the best choice. I love the look and practicality of the French Door fridges - great for smaller spaces. I was all set to buy an LG fridge and now I'm hearing that they're going on fire? Be sure to check Consumer Reports before you buy. Many of the cheaper models are now made in Mexico. I do notice the quality difference when I'm opening and closing fridge doors in the showrooms.

- Q:Hi, I would like to know if steel is an important material in desalination plants. If it is, could you specify what type of steel is used (i.e. flat steel products, long steel products, etc). Thanks.

- yes stainless steel pipes

- Q:I mean, besides the light weight and other graces of Aluminium and Carbon, Steel frames are absolutely out-dated and they have nothing to do these days... or it is still possible to enjoy a nice ride on our heavy old pals?

- Steel is still real, light, and stainless these days! Reynolds 953 stainless steel proves that. Look up Independent Fabrication, link below and the quote from their website. Reynolds 953 is a martinsitic age-hardenable stainless steel. This super metal has an ultimate yield strength of 2000 MPa verses 1400 MPa for Reynolds 853 and 800 MPa for 4130 chrome-moly steel. 3Al-2.5V titanium has ultimate yield strength of 900 MPa. When you take in account the densities of steel and titanium, you find that the strength to weight ratio of 953 is 256 verses 3-2.5 Ti at 200. Yes, your read that correctly. A better strength to weight ratio than titanium. And with all of steel's famed ride quality too.

- Q:Can steel coils be coated with PVC?

- Yes, steel coils can be coated with PVC.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Hot-Dip Galvaniume Steel Sheet of Every Size

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 30 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords