Hot dip Aluzinc Steel Coil in High Quality

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Hot-dip Zinc Coating Steel Building Roof Walls

1.Structure of Hot-Dip Galvanized Steel Sheet Description:

Hot-dip galvanized steel coils are available with a pure zinc coating through the hot-dip galvanizing process. It offers the economy, strength and formability of steel combined with the corrosion resistance of zinc. The hot-dip process is the process by which steel gets coated in layers of zinc to protect against rust. It is especially useful for countless outdoor and industrial applications. Production of cold formed corrugated sheets and profiles for roofing, cladding, decking, tiles, sandwich walls, rainwater protective systems, air conditioning duct as well as electrical appliances and engineering.

2.Main Features of the Hot-Dip Galvanized Steel Sheet:

• Excellent process capability

• Smooth and flat surface

• Workability, durability

• Excellent anticorrosive property

• High strength

• Good formability

• Good visual effect

3.Hot-Dip Galvanized Steel Sheet Images:

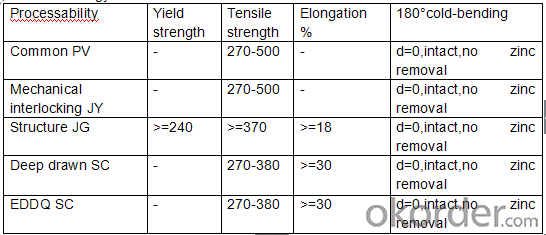

4.Hot-Dip Galvanized Steel Sheet Specification:

Standard: ASTM, JIS,EN

Grade: CS, DX51D+Z,SGCC, SS 230~550,S220GD+Z~S550GD+Z, SGC340~SGC570

Thickness: 0.1mm~5mm

Width: max 2000mm

Coil weight:3-12 MT

Coil ID:508/610mm

Surface structure: zero spangle, regular spangle or minimum spangle

Surface treatment: Chromate treatment, Oiled/dry, skinpassed/non-skinpassed

Packing: Standard seaworthy export package

Technology test results:

5.FAQ of Hot-Dip Galvanized Steel Sheet:

We have organized several common questions for our clients,may help you sincerely:

1.How about your company?

A world class manufacturer & supplier of castings forging in carbon steel and alloy steel,is one of the large-scale professional investment casting production bases in China,consisting of both casting foundry forging and machining factory. Annually more than 8000 tons Precision casting and forging parts are exported to markets in Europe,America and Japan. OEM casting and forging service available according to customer’s requirements.

2.How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

3. How long can we receive the product after purchase?

Usually within thirty working days after receiving buyer’s advance payment or LC. We will arrange the factory manufacturing as soon as possible. The cargo readiness usually takes 15-30 days, but the shipment will depend on the vessel situation.

- Q:How are steel coils used in the manufacturing of automotive springs?

- Steel coils are used in the manufacturing of automotive springs as they provide strength, durability, and flexibility required for suspension systems. The steel coils are shaped and formed into the desired spring shape, ensuring optimal performance and handling of the vehicle.

- Q:and which one is better?i'm looking into buying some aftermarket headers, but companies make them in both chrome and stainless steel

- I know nothing of aftermarket headers so can't help you there, but - chrome is a coating on metal. Stainless Steel is a type of metal.

- Q:What are the various surface finishes available for steel coils?

- The various surface finishes available for steel coils include hot-rolled, cold-rolled, galvanized, coated, and polished finishes.

- Q:I know that steel is generally iron with carbon and probably some other things in it, but I'm doing a research paper on architecture in Tokyo, and touching on the Tokyo Tower.The Tokyo work is larger than the Eiffel Tower by 12 meters, but lighter by 3000 tons. The only reason I can find for the difference in weight is that the Tokyo Tower is made of steel and the Eiffel Tower in made of iron, and since the Tokyo Tower is modeled after the Eiffel, there's really not a substantial difference in the amount of metal used....

- Steel Lighter

- Q:What is the maximum weight capacity for a steel coil lifting device?

- The maximum weight capacity for a steel coil lifting device can vary depending on its design and specifications. It is important to refer to the manufacturer's guidelines and specifications to determine the specific weight capacity for the lifting device in question.

- Q:What are the different types of steel coil edge conditioning methods?

- There are several different types of steel coil edge conditioning methods, including slitting, trimming, chamfering, deburring, and edge rolling. Slitting involves cutting the coil into narrower strips, while trimming removes any excess material from the edges. Chamfering is the process of creating a beveled edge, while deburring removes any burrs or sharp edges. Edge rolling is another method used to smooth and shape the edges of the steel coil.

- Q:Can steel coils be transported by air?

- Yes, steel coils can be transported by air.

- Q:What kind of steel should be used for constructing a steel building?

- Please specify what kind of steel, is it structural steel (like wide flange, channel or Z-section) or reinforcing steel? For structural steel, all steel members that passed the requirement of ASTM-A360 are the best quality. While for reinforcing steel, it should passed the requirement of ASTM-D3963 for epoxy coated and ASTM-A615 (Grade 60) for deformed bars.

- Q:I know that it is used for katanas and swords but what is it and is it good i am pretty sure that it is the process of the steel but can I have a little more information.

- Damascus or Wootz was a type of steel that appeared around 300BC It originated in India before spreading throughout Asia and the Middle East. It was considered a good steel, and for it's date of origin, exceptionally advanced for the level of technology in the ancient world. However the techniques to create the steel were lost forever after a decline in the swords manufacturing. The most popular theory is that the metal containing the required trace elements became less available over time due to unreliable trade routes. In the modern area, many scientists and metallurgists have studied the surviving blades, resulting in many discoveries such as evidence of carbon molecules fused in a crystalline structure. While the blades do provide some clues, it's only a small part of a much bigger picture as to the full process of the metal from raw to finished product. Now many have claimed to have recreated Damascus/Wootz steel, but none are recognised as being authentic. It has become a market ploy these days that draws people to purchasing the blades but all you are actually seeing is one of the many various forms of folded or patterned steel, which has varying degrees of quality, strength etc. We do know the steel was folded similar to the way the Japanese did in creation of old Katana, so often people will sell Damascus steel Katana that are nothing but folded steel swords like others. (Which is beautiful and traditional, but was a process designed to uniform impurities in the metal, something we no longer need to do with modern metals)

- Q:How are steel coils tested for quality?

- Steel coils are tested for quality through a variety of methods, including visual inspections, measurements of dimension and weight, and mechanical tests such as tensile strength and hardness. Additionally, non-destructive testing techniques like ultrasonic or magnetic particle testing may be used to detect any potential defects or flaws within the coils. These comprehensive testing procedures ensure that the steel coils meet the required quality standards before they are used in various industries.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Hot dip Aluzinc Steel Coil in High Quality

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords