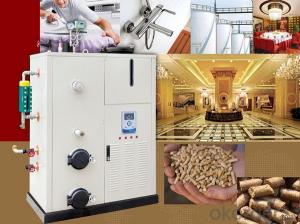

Horizontal Biomass Hot Water Hrsg Boiler

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10 unit

- Supply Capability:

- 10000 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Horizontal biomass hot water hrsg boiler

Specifications

1.Horizontal biomass hot water hrsg boiler

2.30000 Kcal

3.Biomass Pellet Fuel

4.Can be customized

Introduction

Reasonable boiler structure and special combustion method make automatic biomass gasification water boiler solved the deflagration and coking phenomenon from the source. Reasonable boiler structure and special combustion method make automatic biomass gasification water boiler solved the deflagration and coking phenomenon from the source.

Key Features

Control system: microcomputer control system, temperature setting, cycle control and fault alarm function, simple and easy to use.

High automation: we use advanced rotary screw to drive automatic feed device to feed the fuel automatically, only need to fill the storage hopper one time to satisfy 1-2 days need.

Convenient: boiler overall structure is compact, small size, no need to set up a tall chimney, easy installation, low failure rate.

Application Range

It can be widely used in garment manufacturing, food processing industries, hotel services, petrochemicals, schools, hospitals and enterprises, especially for the users in those areas have high requirements on environmental protection and energy saving.

Specification

| Project | Unit | GS0.035 | GS0.08 | GS0.18 | GS0.23 | GS0.7 |

| Rated heating value | Kcal | 3×104 | 7×104 | 15×104 | 20×104 | 60×104 |

| Rated working pressure | MPa | 0 | ||||

| Rated supply and return water temperature | °C | 85/60 | ||||

| Thermal efficiency | % | ≥90 | ||||

| Water yield | L | ≥600 | ≥1500 | ≥3300 | ≥4000 | ≥12000 |

| Reference heating area | m2 | 200~300 | 500~700 | 1000~1500 | 1500~2000 | 4000~5000 |

| Hot and cold water caliber | mm | 50 | 50 | 65 | 65 | 100 |

| Induced draft fan | KW | 0.08 | 0.55 | 0.75 | 0.75 | 3 |

| Blower | KW | 0.1 | 0.1 | 0.1 | 0.1 | 0.1 |

| Heater band | KW | 4 | 4 | 4 | 4 | 4 |

| Feeder-conveyer | KW | 0.25 | 0.25 | 0.25 | 0.25 | 0.4 |

| Chimney exit diameter | mm | dia140 | dia140 | dia140 | dia140 | dia250 |

| Length | mm | 1300 | 2170 | 2620 | 1550 | 2700 |

| Width | mm | 450 | 550 | 600 | 1300 | 1860 |

| Height | mm | 1260 | 1370 | 1600 | 1650 | 2380 |

| Hauled weight | Kg | 380 | 430 | 510 | 780 | 1860 |

| Fuel consumption rate | Kg/h | 8 | 19 | 42 | 56 | 168 |

| Material storage apacity | Kg | 100 | 100 | 200 | 300 | 500 |

Note:

1.The data is for reference only, technical specifications may be subject to change without prior notice.

2. Our products can be customized. If any other parameters are needed, please contact me.

FAQ

Q:What's my consideration when i choose a gas stove?

A: -The style and size of your kitchen.

-The food or cooking style you prefer.

Q:Can i be a distributor of CNBM?

A: Of course you can.

Q:What are the benefits of being your gas stove distributor?

A: - Marketing protection.

- Priority of launching new design.

- Point to point technical supports and after sales services.

Q: How can i become a distributor of CNBM stoves?

A: Contact us immediately for further details by sending us an inquiry.

- Q:Which plants can be used as biodiesel feedstock

- Biodiesel, also known as fuel methyl ester, methyl ester or esterified oil, is the main component of natural vegetable oil or animal fats, such as triglycerides with methanol, ethanol, etc.

- Q:How biogas is produced

- Biogas is a kind of combustible gas produced by the fermentation of microorganisms under anaerobic conditions. As the gas was first found in the marsh, it was called methane. Livestock and poultry manure, straw, sewage and other organic substances in the sealed digesters, under anaerobic fermentation conditions, that is, a large variety of biogas fermentation microbial decomposition transformation, resulting in biogas. Biogas is a mixture of gases that can burn. Biogas is a combustible gas produced by anaerobic digestion of organic matter.

- Q:What toxic gas poisoning!! What's going on!

- If the above ambient air contains a high concentration of methane, so that the oxygen content decreased, it will lead to suffocation, serious will lead to death. If the content of methane in the air to 25--30% will make the occurrence of headache, dizziness, nausea, inattention, incoordination, fatigue, weak limbs and other symptoms. If the concentration of methane in the air over 45--50% will be due to severe hypoxia and dyspnea, tachycardia, coma and suffocation.

- Q:I would like to ask how biogas production

- 2.2.1 fixed arch cover hydraulic digesters?The fixed arch cover hydraulic tank has a cylindrical shape (see Figure 2.1), a sphere (see Figure 2.2) and an ellipsoid (see Figure 2.3). The gas chamber on the upper part of the pool body is completely closed, and with the constant production of methane, the methane pressure increases correspondingly. The continuously increasing air pressure forces a part of the material liquid in the methane tank into the water pressure chamber communicated with the pool body, so that the liquid level in the water pressure chamber is increased. As a result, the water level in the water tank with the liquid level in the body will produce a water level difference, the water level difference is called "water pressure" (that is, the U tube methane pressure meter display value). When the utility model is used for gas, the methane switch is opened, and the methane is discharged under the water pressure; when the methane is reduced, the material liquid between the water pressure returns to the pool body, and the water level difference is continuously decreased, and the methane pressure is correspondingly reduced. The utility model uses a part of the material liquid to move back and forth, which causes the water pressure to change repeatedly to store and discharge methane.There are generally two kinds of biogas digesters, one is made of ordinary cement, and the other is made of glass fiber reinforced plastic, glass fiber is divided into ordinary type and patent type

- Q:I have a bio diesel around 8 degrees when the crystallization of the phenomenon, how can I solve it? Or dewaxing can also, how can I lose the bio diesel

- However, you can also add a distillation process, which can reduce the freezing point of a certain role, and the color of the oil is pale yellow, the price can be high

- Q:Bio diesel production enterprises should be how to classify, GB No.

- At present, bio fuels are mainly used to replace fossil fuels as transportation fuels, such as alternative fuel ethanol and biodiesel. Under the background of the gradual decline of fossil fuel reserves and the increasingly severe environmental protection, the government attaches great importance to bio fuels.

- Q:Biodiesel can be used directly as fuel for diesel engines

- Otherwise it will cause some damage to the engine

- Q:Biogas digesters and septic tanks in rural areas which utility

- Biogas can be used as gas. Septic tank. See you also do not sow.

- Q:Is fatty acid methyl ester biodiesel?

- Only by adding some additives to reconcile can be called bio diesel. Therefore, biodiesel is the main component of fatty acid methyl ester

- Q:What is the use and harm of methane

- Use of biogas:Comprehensive up in the following aspects: (a) methane is beneficial to solve the energy problem in rural areas. A 3 - 4 family, built a 10 cubic meters of methane fermentation pool, as long as sufficient raw materials, and good management, can solve the problem of lighting, cooking fuel. (two) is conducive to the promotion of biogas the development of agricultural production. Since the establishment of a large number of livestock and poultry manure into biogas, biogas fermentation, biogas production, and a large number of high quality organic fertilizer retting, expand the source of organic fertilizer. In biogas fertilizer crop not only enhances the ability of drought resistance and antifreeze, and improve the survival rate of the biogas fertilizer not only saves. Spraying amount of fertilizers and pesticides, but also conducive to the production of green pollution-free food. (three) the biogas is conducive to promote the development of animal husbandry. Set up biogas, will help solve the "three" (fuel, feed and fertilizer). The contradiction, to promote the development of animal husbandry. (four) the biogas is conducive to improve health conditions. Who built a biogas digesters farmers realize, using biogas as fuel, smokeless clean, clean and convenient. Some feces, garbage and sewage are good raw materials for biogas fermentation, with the raw material into the digester bacteria, parasite eggs, in the digesters closed fermentation and killed. So as to improve the environmental health conditions in rural areas, are beneficial to human and animal health

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Horizontal Biomass Hot Water Hrsg Boiler

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10 unit

- Supply Capability:

- 10000 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords