Homemade Beer Fermentation with CE Certificate

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 500 unit/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

Description:

Processing: Storage Tank, cutting-rolling-welding-polishing-assembling-testing-warehousing

Condition: New

Place of Origin: Zhejiang, China (Mainland)

Brand Name: KUNBO

Model Number: bright tank, KB-006

Processing Types: Alcohol

Voltage: 380V, 50HZ

Certification: B&V; CE

Image:

Packaging & Delivery

| Packaging Details: | export standard package |

|---|---|

| Delivery Detail: | 25 - 45 days after deposit received |

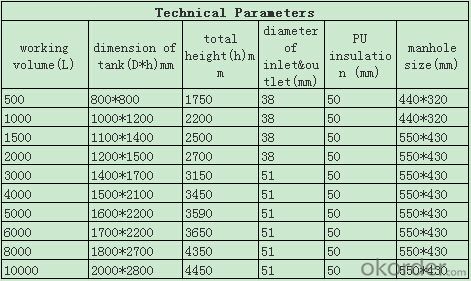

Specifications

1.manhole 2.CIP spraying ball 3.adjusting feet 4.sample valve 5.temperature gauge 6.pressure gauge 7.level gauge

- Q:It keeps showing a sign on the display like 2 straight lines and a line underneth i cannot fing it in manual and it is making a funny low sound

- Im so sory i do not know i wish i could help you Hi i have had one of these boilers fitted the other day and even with the cupboard fitted over it its to loud, infact i have to keep turning it off because its driving me mad as i sleep in the next room, i have turned the thermostat down as low as possible to stop the heating from keep coming on in the summer which it still does i wish we never had it now I mean is it suposed to make this much noise ? why do the radiators keep coming on when i have it set to 5'o degrees ?

- Q:i am looking to buy a home built before 1890 and it MUST remain as is with it's natural gas boiler. how efficent is this system v's using forced air heating. keep in mind this home is 4800 sq ft and is all plaster walls and hardwood floors. i am sure i could help by using the 3 fireplaces but i am still concerned about the boiler having never seen one before.

- alot with natural gas because you dont need to wait for the water to boil like you do with elefctricity!

- Q:Boiler certificate expired, how to do, the specific process is?

- Of the provisions of the review to allow qualified, and in the original certificate issued by the issuing department review of qualified chapter.

- Q:What is the boiler steam

- Boilers can be divided into industrial boilers, power boilers, marine boilers and locomotive boilers; according to the boiler outlet pressure can be divided into low pressure, medium pressure, high pressure, high pressure, subcritical pressure, supercritical pressure boiler;

- Q:I am in the process of installing a hot water gas boiler Weil Mclan CGI 4 . I have seen many boilers placed on a cemented platform. I wonder whether a platform is necessary or can I place the boiler on the floor itself. Any advice will be highly appreciated.

- Nice unit. I just did the same thing 2 years ago. The pad you see under those boilers is for #1: leveling #2 protection against water damage to boiler (should your basement take on water). My friend, If you have to ask that question, I dare say that you've never installed a boiler before. There are a hundred ways to cause injury (or DEATH) if it is not done correctly. Please have someone who is qualified work with you. Keep in mind that should you ever have a fire or worse occur with this unit, and it wasn't installed by a licensed technician, YOU CAN AND WILL VOID YOUR INSURANCE.

- Q:that we keep on gas stove.

- Use okorder

- Q:My boiler has broken unexpectedly, causing loss of heating or hot water. I am a homeowner and, apparently stupidly, thought the boiler would be covered by either my buildings or contents insurance.Basically, i have no money or savings and struggle to pay bills monthly. Of course, it will take up to a year for me to save up for a new boiler, but many people i have spoken to have said there are schemes which could help me with a new boiler.I don't claim any benefits, though i would be entitled to working tax credits if i wanted to applying them. But of course, that would take months! does anyone know of schemes with could help me, or should i just prepare for a cold year?!?

- have you called your local utilities, or local govt ? sometimes they know of organizations that can help. personally i would start calling the churches in my area and ask them to post for any help, you may be very surprised at the hvac/plumbers who may come to your aid. bundles nice work on the links but most of those will take a year just to get an answer, but i like the effort.. another thought though on the engineers, try calling the trade schools and see if the teachers and students have any fixit programs.

- Q:Why is my radiator making the noise of running water, despite the heating being off and the radiator not being the least bit warm?It only does this occasionally. What is the most economic setting to have the boiler on?

- First, if it's a hot water system, check the psi on the boiler. If you don't have an auto feed, you have to maintain 15 to 20 lb. in the system. You could be low on water psi and may have air in the system. Check the psi and bleed the air out of your radiators. If it's a steam system, you shouldn't have any water in the radiators, Unless you have a leak in the hot water coil inside the boiler. But if that was the case, would be getting water coming out your steam vents. Normal setting for temp. on the boiler is 160 for the low setting and 180 for the limit. This is the best answer I can give you without seeing the system. A lot of other things can come into play, but this is the most common problem.

- Q:Boiler energy saving how to achieve environmental protection

- Boiler and auxiliary equipment, energy-saving emission reduction technology Boiler auxiliary equipment is to achieve the combustion medium, burning, burning, burning and material flow smooth basic point, while the technical basis for energy saving and environmental protection.

- Q:what are the heat transfer mode in a boiler system?

- Most boilers utilize radiation, conduction and convection as the modes of heat transfer. Radiation from the burner flame, conduction and convection from the hot gases to heat the boiler tubes and conduction and convection to heat and boil the water. If there is a boiler feed water or combustion preheater, they would utilize conduction and convection.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Homemade Beer Fermentation with CE Certificate

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 500 unit/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

New products

Hot products

Related keywords